Muda, Mura, and Muri: The Toyota 3M Model Explained

| Audience: | Manufacturing and Healthcare Executives, Lean Management and Continuous Improvement Professionals, Operational Leaders and Safety Officers |

| Last updated: | September 2, 2025 |

| Read time: | 15 min |

- Muda (Waste): Cut out non-value-adding tasks like unnecessary steps, idle time, and rework to boost productivity.

- Mura (Inconsistency): Balance workloads and standardize processes to prevent bottlenecks and burnout.

- Muri (Overload): Avoid pushing people or machines beyond limits by improving planning, rest, and ergonomics.

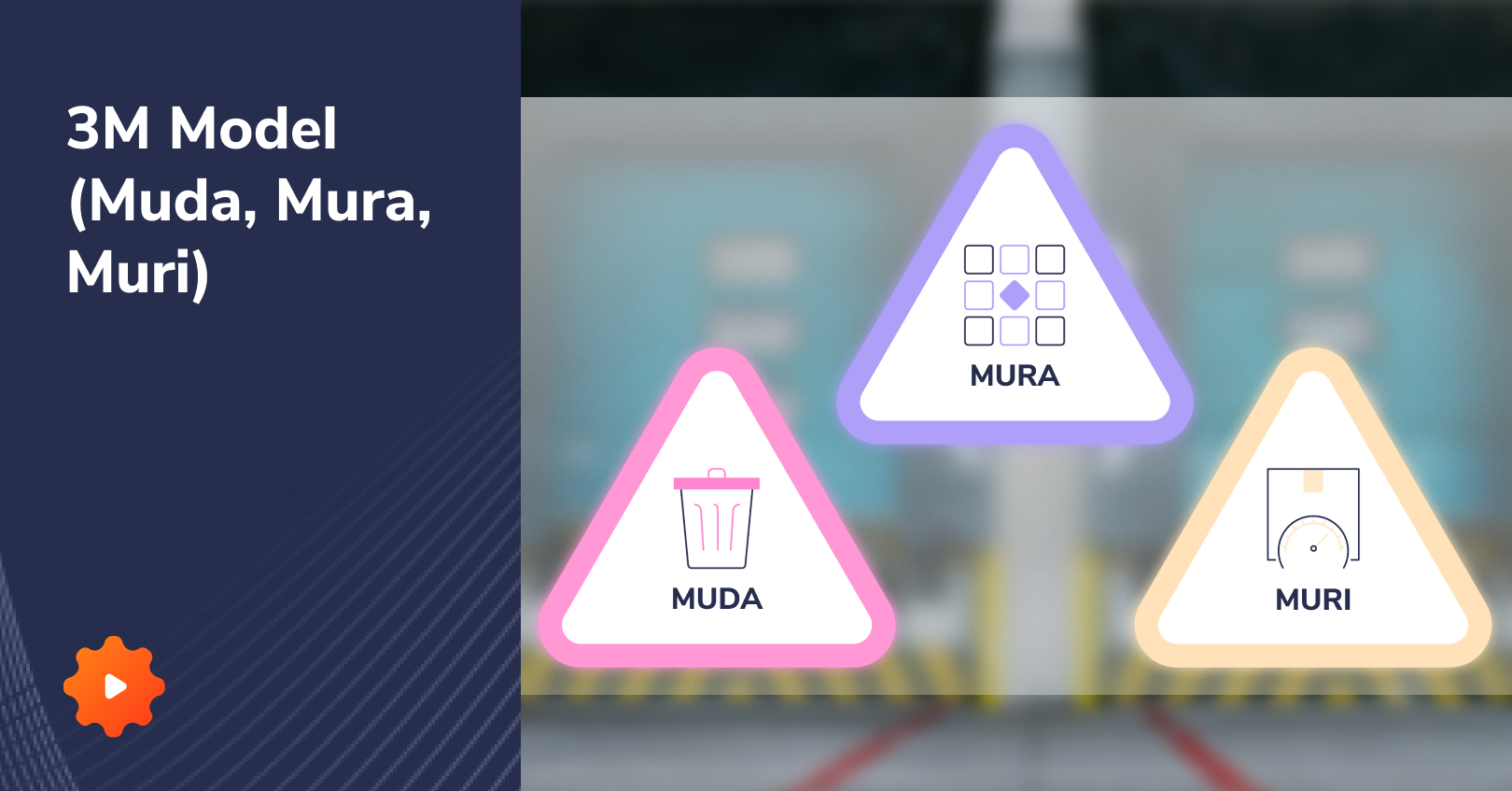

Originally developed as part of Toyota’s lean manufacturing system, the 3M model focuses on three things that slow teams down:

- Muda = waste

- Mura = inconsistency

- Muri = overload

These issues don’t just waste time. They create stress, cause mistakes, and hurt quality.

The good news? Once you learn to spot the 3Ms, you can fix them. And this isn’t just for factories: teams in healthcare, technology, logistics, and even startups employ the same approach.

In this guide, you’ll learn what muda, mura, and muri mean, how they’re connected, and how to reduce them in your work.

Let’s make your workflow smoother, faster, and a lot less frustrating.

What is the Toyota 3M model? Concept and method explained

The Toyota 3M model, Muda, Mura, and Muri, is a framework to streamline your workflow, eliminate waste, and reduce stress.

Toyota’s lean manufacturing philosophy is all about doing more with less: less time, less waste, less effort. It focuses on creating value for the customer while making processes as efficient and smooth as possible. One of the core ideas behind this is the 3M model, which helps teams spot and eliminate problems that slow things down or waste resources.

So, what’s 3M? It stands for:

- Muda (waste): Any activity that doesn’t add value. Think of things like overproduction, waiting, or unnecessary motion.

- Mura (inconsistency): Unevenness in workflows or production. For example, when some team members are overloaded while others are idle.

- Muri (overburden): Pushing people or machines beyond their limits, which leads to stress, mistakes, and breakdowns.

Together, these three help you identify what’s holding your process back.

Here’s why the 3M model matters: When you remove muda, mura, and muri, things start to flow better. You reduce delays, improve quality, and avoid burnout.

By using the 3M model, you’re not just fixing problems; you’re creating a culture of continuous improvement. You’ll see the benefits in productivity, happier employees, and better results for your customers.

To truly understand why this model works, it is helpful to know its origins. Let’s take a quick look at its roots.

Manufacturing leaders leverage Tervene to reduce waste

Where did the 3M model come from?

The 3M model didn’t start in a fancy lab. It originated from real-world challenges in post-World War II Japan.

At that time, Japan had limited resources. Factories couldn’t afford waste. Toyota needed a better way to build cars with fewer materials, fewer workers, and less space. So they got creative.

One of the key people behind this was Taiichi Ohno, an engineer at Toyota. He examined every step in the production line and asked, “Does this add value?” If not, it had to go. That thinking became the foundation of lean manufacturing.

The 3Ms came from Ohno’s observations on the shop floor. He realized that removing these three problems made everything work better.

The idea wasn’t just about making cars. It was about making any process smoother, brighter, and more human.

Today, the 3M model is used far beyond Toyota.

Now that you know the background, let’s dive into the first “M” (muda). You’ll learn what it looks like and how to spot it.

What does muda mean?

Muda is a Japanese word that means waste: anything that uses time, money, or effort but doesn’t add value for the customer. In lean thinking, identifying and eliminating muda is a significant endeavor.

| Type of waste | What it looks like | How to reduce it |

| Transportation | Moving products between locations | Rearrange layout to shorten travel time |

| Inventory | Storing too much stock | Order smaller batches, more often |

| Motion | Extra walking or reaching | Place tools closer to where they’re used |

| Waiting | Idle time between steps | Improve scheduling or handoffs |

| Overproduction | Making more than needed | Align output to actual demand |

| Overprocessing | Doing more work than necessary | Simplify steps or approvals |

| Defects | Errors needing rework or scrap | Improve training or quality checks |

You’ll find muda everywhere: on factory floors and in offices. Think of paperwork that no one reads, meetings that go nowhere, or products sitting in storage collecting dust.

To eliminate muda, start by asking: Is this task truly adding value? If the answer’s no, it might be a waste. Try mapping your process step by step and look for the 7 types of waste, like overproduction or defects.

Cutting muda helps teams move faster, reduce costs, and focus on what matters. And once you start spotting it, you’ll see it everywhere.

But waste isn’t the only issue. Next up is Mura. It’s sneaky, but it can slow down your work just as much.

What is mura, and why does it matter?

Mura means unevenness or inconsistency. It shows up when work isn’t balanced: some days you’re overloaded, other days you’re waiting around. That kind of stop-and-go flow makes everything more complicated.

Mura hurts productivity, quality, and even team morale. It causes bottlenecks, burnout, and delays. And when customers receive their orders late or notice varying levels of quality, they take notice.

Here are some common examples of mura:

- Scheduling → Rushing to meet tight deadlines, then sitting idle

- Demand → Huge spikes followed by slow periods

- Quality → Inconsistent work standards from one shift to another

To reduce mura, you can use a few simple Lean tools:

- Takt time → This sets a steady pace based on customer demand

- Standard work → Clear, repeatable steps so everyone follows the exact best method

- Work leveling (heijunka) → Spreading work evenly to avoid big swings

By smoothing out the flow, you make life easier for your team and deliver more reliably to your customers. Less stress, better results.

Once you start spotting mura, you can fix it, and that’s a big win for everyone.

When things aren’t consistent, people and machines often get pushed too hard. That brings us to the third “M”: muri.

How does muri cause problems?

Muri means overburden; it refers to placing excessive stress on people, machines, or systems. It’s when the workload is just too much, too fast, or too often. And it’s a recipe for trouble.

When you push too hard, mistakes happen. Machines break down. People burn out. Over time, muri leads to low morale, more downtime, and higher costs.

You’ll see muri in situations like:

| Overburdened area | What it looks like | Simple way to reduce it |

| People | Rushing, skipping breaks, frequent errors | Adjust workload, schedule recovery time |

| Equipment | Running non-stop, frequent breakdowns | Build in rest time and preventive maintenance |

| Tasks | Too complex or physically demanding | Simplify steps or use ergonomic tools |

| Processes | Unclear expectations, unrealistic timelines | Clarify goals, improve planning |

| Communication | Endless meetings or unclear messages | Streamline updates, use visual boards |

When you remove muri, everything runs smoother. People feel better, equipment lasts longer, and quality goes up.

You’re not just avoiding breakdowns. You’re building a healthier, more efficient workplace. And that benefits everyone.

You’ve seen the three M’s on their own. Now let’s look at how they connect, and why tackling just one isn’t enough.

Eliminate hidden inefficiencies with Tervene’s tools

How do muda, mura, and muri connect?

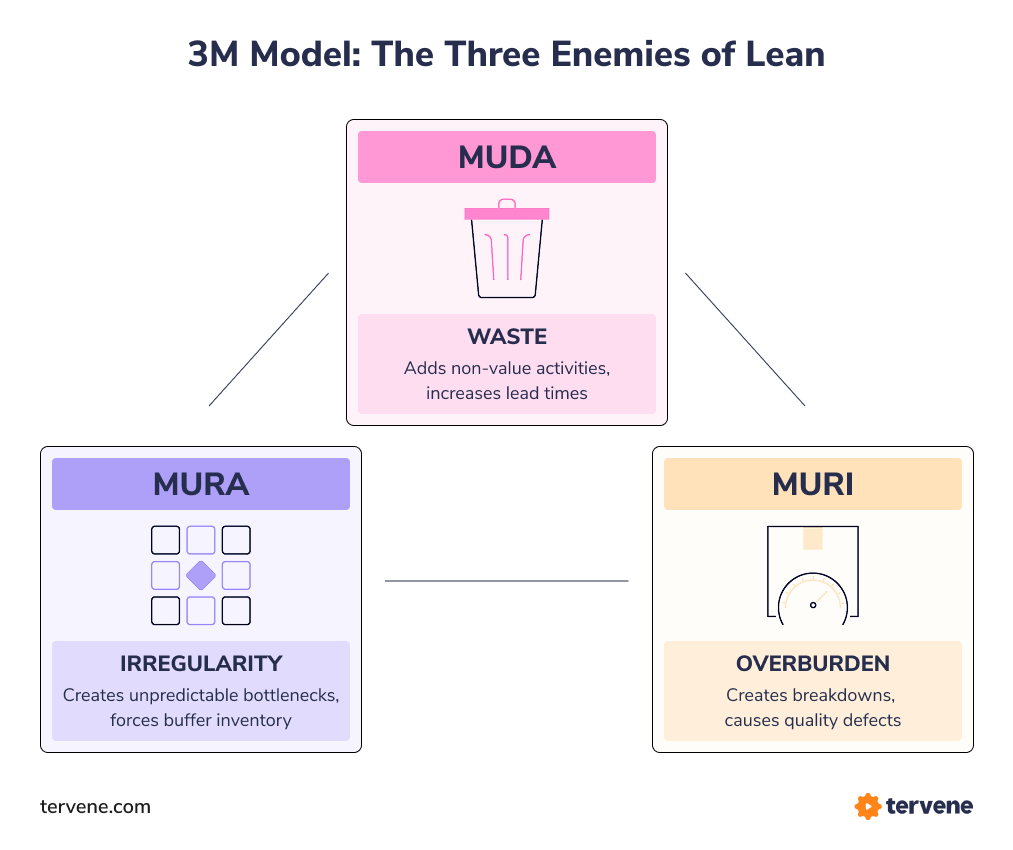

The 3Ms don’t exist in isolation. They’re deeply connected. One often leads to the other.

For example, if your schedule is uneven (mura), some employees may get overloaded during peak times. That’s muri. When people are overworked, they make mistakes or rush, creating muda, or waste, such as defects or rework.

Here’s a simple way to picture it:

- Mura (inconsistency) → causes

- Muri (overburden) → leads to

- Muda (waste)

To help you visualize how the 3Ms affect each other, here’s a table with simple cause-and-effect examples.

| If you ignore… | You might see this happen… | Why it matters |

| Mura | Some shifts are slammed, others are slow | Creates muri on busy days, and muda when idle |

| Muri | Employees rush and make errors | Leads to muda like rework and defects |

| Muda | Work takes longer than needed | Hides mura and muri you haven’t fixed |

If you only focus on removing waste but ignore the root cause (such as inconsistent workloads), the problems will recur. That’s why lean thinking always looks at all three together.

Let’s say a team keeps making errors. You fix the defects (muda), but the real issue is that they’re overloaded (muri) because work isn’t balanced (mura). Solve the imbalance, and the errors begin to disappear naturally.

When you see how they overlap, you can tackle the real issues, not just the symptoms. Fix one, and you’ll often fix the others too.

This isn’t just theory. Companies everywhere are applying the 3M model to solve real problems. Here’s how they do it.

How do companies use the 3M model today?

The 3M model isn’t just a Toyota thing anymore. Companies around the world use it to improve how they work, regardless of whether they’re building cars, writing code, or delivering care.

In manufacturing, teams use the 3Ms to spot delays, machine breakdowns, or excess inventory. For example, a car parts supplier reduced muda by rearranging tools to cut down walking time. They balanced shifts to reduce mura and scheduled regular breaks to avoid muri on their staff.

In logistics, delivery companies use the 3Ms to streamline routes and loading processes. Less waiting (muda), fewer last-minute changes (mura), and no overloaded trucks (muri) mean faster, safer deliveries.

In healthcare, hospitals apply 3M thinking to patient flow. One clinic reduced wait times by balancing appointment scheduling (mura) and redesigning nurse workspaces to minimize extra steps (muda). They also improved shift planning to avoid burnout (muri).

Tech companies use it too. Dev teams reduce muda by cutting unneeded features, fix mura by smoothing out sprint cycles, and prevent muri by setting realistic workloads.

Even startups and service industries benefit. A small agency might utilize the 3Ms to manage client work more effectively: stop overbooking (mura), reduce last-minute crunches (muri), and eliminate repetitive tasks (muda).

The best part? You don’t need a big budget to use this model. Just start by asking: Is there waste, imbalance, or overload here? If the answer is yes, there’s room to improve.

You don’t need to run a factory to use this. Let’s walk through how you can apply the 3M model in your day-to-day work.

How do you apply the 3M model in your work?

You don’t need to be a factory manager to use the 3M model. Whether you’re in a small business, a startup, an office, or a team of one, you can spot and reduce muda, mura, and muri in your daily work.

Here’s a step-by-step guide to help you get started.

1. Observe your process

Start by watching how things happen, not how they’re supposed to happen.

- Walk through your workflow.

- Pay attention to delays, confusion, or repeated effort.

- Look for signs of stress, waiting, or things piling up.

Even just shadowing someone for an hour can reveal issues you’ve never noticed.

2. Ask why

When something feels off, ask why, not just once, but five times if you can. The “5 Whys” method helps you dig deeper past symptoms and uncover the root causes.

Example:

- “Why is this taking so long?”

- “Because we’re waiting on feedback.”

- “Why are we waiting?”

- “Because the reviewer’s overloaded.”

Now you’re uncovering muri and maybe even mura.

3. Spot the 3Ms

Look through the lens of each “M”:

- Muda → Are we doing things that don’t add value? (Extra steps, rework, unused reports?)

- Mura → Is the work uneven or unpredictable? (Last-minute rushes, quiet periods?)

- Muri → Is anyone or anything pushed too hard? (Tight deadlines, heavy lifting, long hours?)

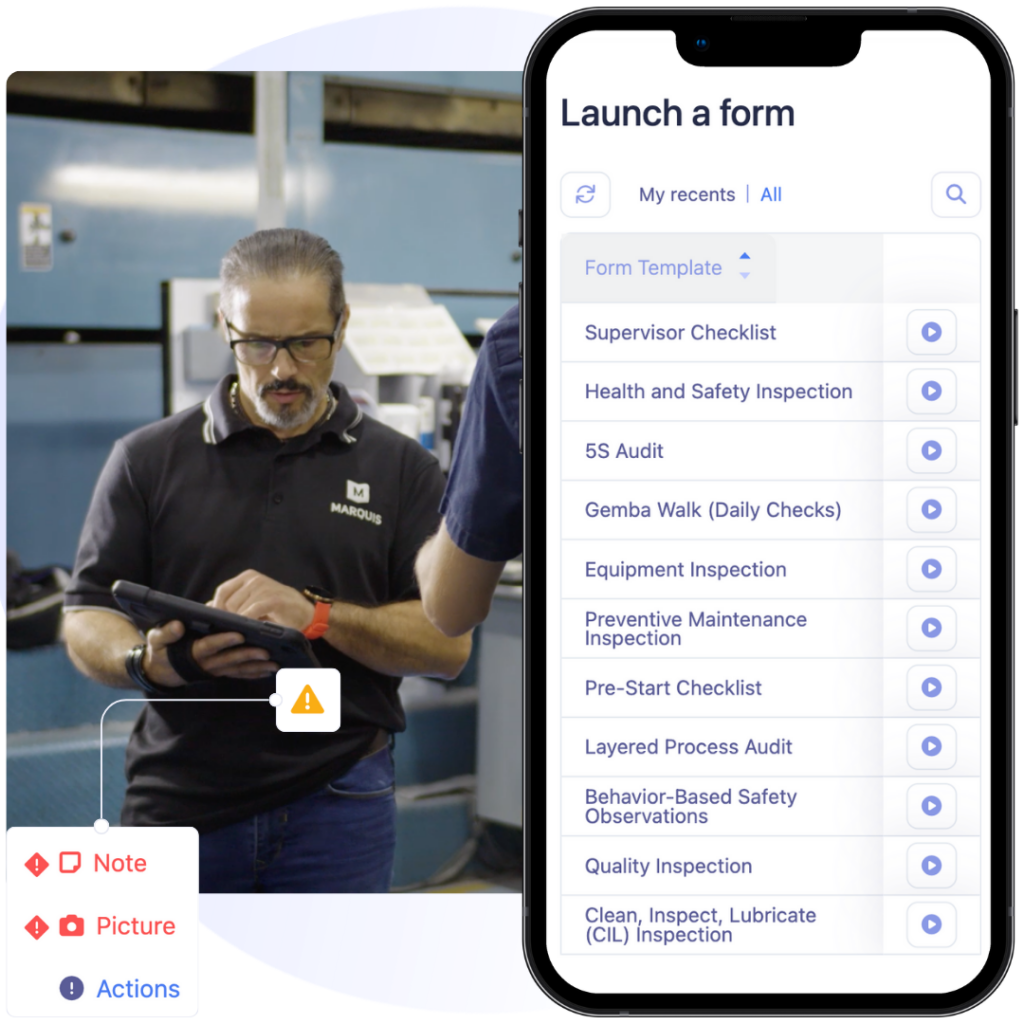

Document what you see with simple notes or checklists.

4. Engage your team

You don’t have to do this alone. Ask your team what frustrates them, slows them down, or causes them to burn out. People closest to the work often know the most.

Try short improvement huddles or informal chats. Keep it open and judgment-free.

5. Use lean tools that support the 3M model

There are a few simple tools you can use to spot and solve problems:

- Value Stream Mapping → Draw your entire process from start to finish and identify areas for improvement, such as waste or bottlenecks.

- 5S → Organize your space (Sort, Set in order, Shine, Standardize, Sustain) to reduce motion and confusion.

- Kaizen → Use minor, continuous improvements instead of waiting for a big fix.

These tools aren’t just for big companies. You can use them to streamline emails, meetings, customer service, or product development.

6. Try digital tools like Tervene

Tervene is a platform that helps teams manage business operations and apply lean practices. You can use it to:

- Standardize tasks and business operations

- Track problems and improvements

- Support team communication

- Spot muda, mura, and muri in real-time

It’s beneficial if you manage multiple teams or locations and want everyone aligned.

You don’t need a major project to start using the 3M model. Just pick one area that feels messy or frustrating. Use the steps above to observe, ask questions, and start making improvements.

Teams using Tervene often see quick wins just by making their routines more consistent. One operations leader shared how it helped streamline communication and meetings:

You’ll be surprised how quickly things get better: less chaos, clearer work, and more time for what matters.

Need help getting started? Use this table to walk through the 3Ms in your workflow.

| 3M | How to spot it | Example | Simple fix |

| Muda | Tasks that don’t add value | Rewriting the same report 3 times | Clarify what’s needed up front |

| Mura | Unpredictable work or demand | 3 deadlines on Monday, none on Tuesday | Spread work evenly over the week |

| Muri | People or tools under too much pressure | One person handles 80% of customer calls | Share workload or add backup support |

When you put this into practice, the benefits become apparent quickly. Here’s what you can expect when you reduce muda, mura, and muri.

What are the benefits of reducing the 3Ms?

When you eliminate muda, mura, and muri, everything works more efficiently. You get more done with less stress, and your team (and your customers) notice the difference.

Here’s what improves when you tackle the 3Ms:

- Efficiency increases → Less wasted time and effort result in smoother workflows and faster results.

- Costs decrease → Fewer mistakes, delays, and unnecessary steps result in cost savings.

- Quality improves → Consistent, well-paced work leads to fewer defects and better outcomes.

You’ll also build a healthier, more motivated team. People work better when they’re not overwhelmed or constantly firefighting. That means:

- Happier teams → Less burnout, better focus, and a stronger sense of control.

- More satisfied customers → Faster service, fewer errors, and more reliable delivery.

Over time, reducing the 3Ms makes your whole organization stronger. You become more agile, more resilient, and better equipped to handle change.

That said, it’s easy to fall into a few traps when using this model. Let’s go over what to watch out for.

What should you watch out for?

Using the 3M model can be a game changer, but only if you apply it correctly. There are a few common pitfalls that can slow you down or lead to frustration.

1. Focusing only on waste (muda)

It’s easy to spot wasted time or materials, so many teams jump straight into cutting muda. But if you ignore mura (inconsistency) and muri (overburden), those same wastes will keep coming back.

For example, fixing delays without fixing uneven workloads won’t last. Always look at the big picture.

2. Overcomplicating the process

Lean doesn’t have to be complex. You don’t need a massive plan to get started. Some teams overthink it, create too many charts, and get stuck in meetings. Start small. Observe. Ask questions. Make one simple change. Then build from there.

3. Ignoring the human side

The 3M model isn’t just about efficiency. It’s about people. If your changes make things more complicated for your team, they won’t stick.

Involve people early. Ask for input. Listen to what frustrates them. Often, they already know where the most significant problems are.

4. Chasing perfection

You’ll never eliminate every waste or imbalance. And that’s okay. Focus on progress, not perfection. Small wins add up over time.

When you keep the 3Ms balanced and stay practical, you’ll create real, lasting improvement.

Now that you know what works (and what doesn’t), let’s wrap it all up with a quick takeaway you can carry forward.

Start using the 3M model today

Suppose there’s one thing to remember about muda, mura, and muri. In that case, it’s this: the 3M model is a practical, people-focused approach to identifying what’s slowing you down and taking action.

Each “M” gives you a different lens:

- Muda shows you where time, effort, or materials are being wasted.

- Mura reveals where things are inconsistent or unpredictable.

- Muri highlights where people or systems are being pushed beyond their limits.

Used together, they help you build more innovative processes, reduce frustration, and improve results without burning people out.

The 3M model isn’t just for factories. It works in any industry, on any team. You can apply it to meetings, emails, customer support, software development, or daily business operations. Anywhere there’s work, the 3Ms can help you improve it.

Start small. Select one workflow and examine it for signs of waste, overload, or inconsistency. Don’t try to fix everything at once. Ask questions. Stay curious. Keep learning.

And remember, you don’t have to do it alone. Tools like Tervene can help you apply lean thinking more easily by standardizing tasks, engaging teams, and identifying issues in real-time.

Continuous improvement is about making things a little better, one day at a time. The 3M model is your guide to doing just that, with clarity, confidence, and less chaos.

Discover Tervene’s Lean Daily Management System

Tervene is a Lean Daily Management System (LDM) that drives operational control, leadership accountability, problem-solving, performance improvement, and decision-making at every organizational level.

Implement a Lean Management System

Build a culture of continuous improvement with tools that strengthen operational control, accountability, and problem‑solving.

Industry leaders use Tervene’s Lean manufacturing tools to eliminate waste, reduce process variation, and deliver more value at every level of their organization.

Discover Tervene’s Lean manufacturing tools .wp-block-media-text li { padding-bottom:5px }

FAQ: 3M Model (Muda, Mura, Muri)

The Toyota 3M model is a lean management concept that focuses on eliminating three key process issues: Muda (waste), Mura (inconsistency), and Muri (overload). It helps organizations streamline operations, reduce inefficiencies, and improve quality.

Muda refers to any activity that consumes resources but adds no value to the customer. There are 7 types of Muda, including overproduction, waiting, excess inventory, motion, transportation, overprocessing, and defects.

Mura means unevenness or inconsistency in workflows. It leads to bottlenecks, idle time, and overburden during peak periods, which reduces productivity and impacts team morale and product quality.

Muri stands for overburden—placing excessive stress on people, equipment, or systems. It often results in errors, burnout, breakdowns, and costly downtime.

These three wastes are interlinked: Mura often causes Muri, which in turn leads to Muda. Addressing all three simultaneously ensures long-term efficiency and improvement.

While born in manufacturing, the 3M model is now used across healthcare, logistics, technology, and services to optimize processes and improve operational flow.

Start by observing daily workflows, identifying signs of waste, inconsistency, or overload, and using lean tools like 5S, Value Stream Mapping, or Standard Work to make improvements.

-

Muda: Repetitive reporting, excessive meetings, or unused inventory.

-

Mura: Uneven workloads between team members or shifts.

-

Muri: Employees skipping breaks or machines running non-stop.

Eliminating the 3Ms improves efficiency, product quality, employee well-being, and customer satisfaction, while reducing costs and operational risks.

Lean tools such as Kaizen, 5S, Heijunka (work leveling), Standard Operating Procedures, and continuous improvement routines support the practical application of the 3M model.