- Break problems down clearly → Define what’s really going on, map current processes, and dig deep with root cause analysis.

- Collaborate on lasting solutions → Bring the right people together to brainstorm, plan, and implement fixes that stick.

- Foster continuous improvement → Track results, refine processes, and share learning so improvements spread across the organization.

Problems pop up every day: missed deadlines, quality issues, delays, confusion between teams. You’ve probably seen quick fixes that don’t last.

That’s where A3 problem-solving comes in. It helps you understand what’s going on, bring the right people together, and create solutions that stick; in manufacturing and beyond.

We’re here to help you get started, so we put together this guide. In it, you’ll learn:

- What lean A3 thinking is and why it works

- When (and when not) to use it

- Who to involve in the process

- Each step, from defining the problem to checking if it worked

- Tools and tips to make it easier in 2025

You don’t need to be an expert. You just need a willingness to slow down, think clearly, and solve the right problem. Let’s get started with the basics.

What is A3 problem-solving? Manufacturing and Six Sigma definition

A3 problem-solving is a simple, structured way to tackle tough problems through a clear, structured path: define the problem, find the root cause, test possible solutions, and make sure the fix lasts. It’s collaborative, visual, and all fits on one page, keeping everyone aligned and focused on real progress.

It comes from Toyota and is part of what made their production system so efficient.

The name “A3” comes from the paper size (11″ x 17″) used to lay out the whole problem (start to finish) on one sheet. That’s the key: clear thinking, all in one place.

A3 thinking helps you:

- Understand the real problem

- Break it down into manageable parts

- Involve the right people

- Focus on facts, not opinions

Just follow a logical flow: define the problem, find the root cause, try countermeasures, and keep what works. Just grab a sheet (or a template, or even a digital tool), walk through each step with your team, and write things down as you go.

It’s all about the thinking behind it. Once you get the hang of it, you’ll solve problems faster and make smarter decisions.

Now that you know what it is, let’s talk about why A3 is especially useful.

Why should you use the lean A3 approach in 2025?

In 2025, things move fast across all industries. A3 problem-solving helps teams tackle issues amid the chaos. Here’s why A3 is worth using today:

- It gives clarity → no more vague problem statements, thanks to the visual aid.

- It aligns your team → everyone sees the same facts and goals.

- It focuses on root causes → not just symptoms.

- It supports lean thinking → cutting waste, improving flow.

- It builds a habit of continuous improvement.

You don’t need a big team or fancy tools. A3 reports are flexible and work across industries. For example, a modern factory used it to cut downtime just by uncovering a small issue in their setup process. A software company used it to reduce customer support tickets by solving a hidden usability problem.

You’ll also see better communication. The one-page format forces you to keep it clear and simple, so even busy execs can quickly get on board.

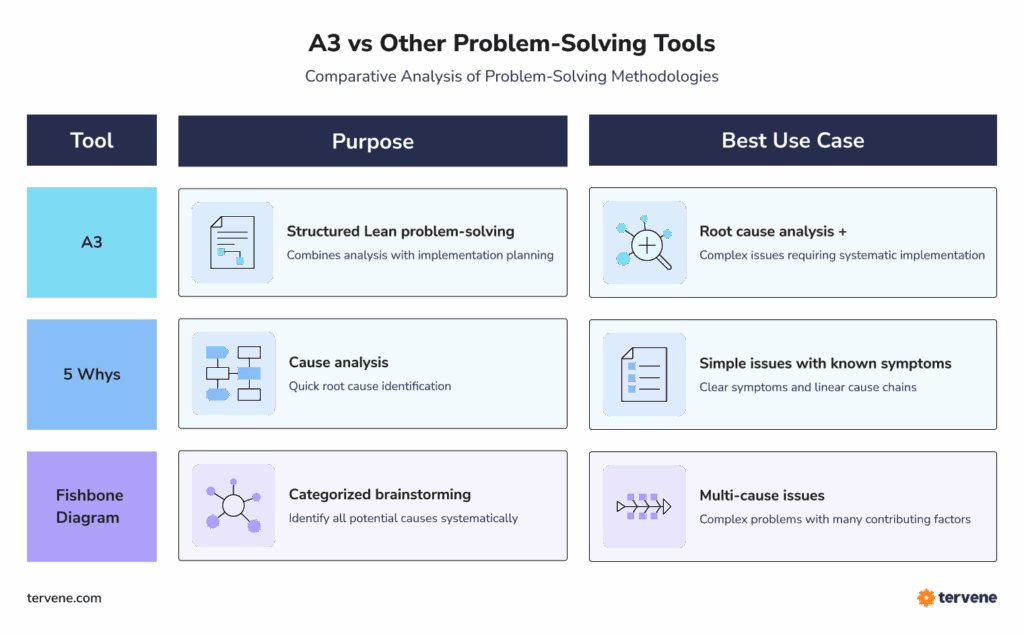

Of course, A3 isn’t for everything. Here’s how to know when it’s the right approach—and when it’s not.

Industry leaders leverage Tervene to solve issues faster

When is A3 the right tool?

A3 problem-solving isn’t for every situation, but when it fits, it’s powerful.

Use it when:

- A problem keeps coming back

- Multiple teams are involved

- Quality or performance is slipping

- The cause isn’t obvious

It’s great for deeper issues that need a clear, team-driven solution. If you’ve tried quick fixes and they didn’t stick, A3 can help you step back and solve the root cause.

But don’t use A3 reports for everything:

- Skip A3 for simple fixes → e.g., refilling a printer doesn’t need a report.

- Don’t use it in emergencies → fast action beats discussion during safety incidents or outages.

- Avoid it without team input → A3 is for collaboration, not solo decisions.

So, how do you know it’s the right time for an A3 document? Look for problems that feel “stuck” or come with lots of opinions but no clear facts. If you hear, “We’ve tried everything,” that’s a strong sign A3 could help.

To make it even clearer, here’s a quick comparison of when A3 works best:

| Situation type | A3 reports | Quick fix | Emergency response |

| Repeating or complex problems | ✅ Best fit | ❌ | ❌ |

| Obvious, easy-to-fix issues | ❌ Overkill | ✅ Ideal | ❌ |

| Time-critical or safety emergencies | ❌ Too slow | ✅ | ✅ Best fit |

| Involving multiple teams or causes | ✅ Effective | ❌ | ❌ |

| Long-term improvement focus | ✅ Strong alignment | ❌ | ❌ |

Once you’ve picked the right problem, the next question is: who needs to be in the room? Let’s build your team.

Who should be involved in building an A3 report?

A3 problem-solving works best when the right people are at the table. A big group? Don’t need one, just the right mix of roles and perspectives.

Here’s who to include:

- Team lead → the person who keeps things on track and guides the process

- Problem owner → someone close to the issue who sees it day to day and has a good understanding of its current condition

- Key stakeholders → people from other departments who are affected or can help

Cross-functional collaboration is essential. Many problems cross team or department lines, so it’s important to bring in different viewpoints. Someone from finance may see costs. Operations might spot delays. Customer service may notice what frustrates users.

When you combine those insights, you get a clearer picture.

Aim for a small but focused team: usually, 3 to 6 people is plenty. That’s enough to get different ideas without slowing things down. Look for people who are:

- Directly involved

- Open to feedback

- Willing to dig into facts

And, don’t just pick managers. The best input often comes from frontline employees who live the problem every day.

When the right people work together, you’ll uncover better insights, make smarter decisions, and create solutions that stick. That’s the heart of good A3 problem-solving.

With the team ready, it’s time to walk through the A3 process, step by step.

Standardize and structure your continuous improvement initiatives with Tervene’s tools

What does the A3 thinking process look like?

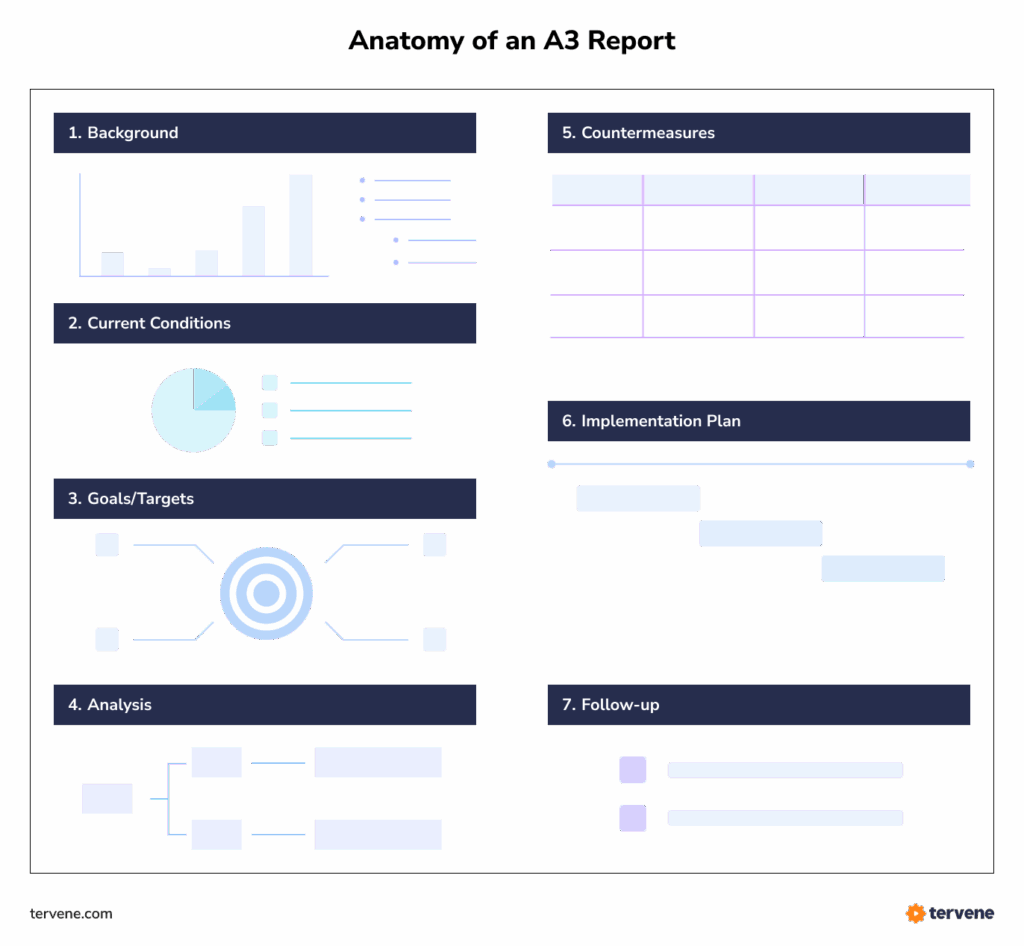

Think of the A3 process as telling the story of a problem: what’s wrong, why it happened, what you’ll do about it, and how you’ll make it stick.

It’s A3 thinking at its core: using visuals, working as a team, testing ideas, and improving along the way. The process is flexible and iterative, so refining steps is just part of the journey.

Before we dive into the details, here’s a high-level view of the full A3 process to keep in mind as you go:

| Step | What you do | Key tools/methods |

| 1. Define the problem | Clarify what’s wrong and why it matters | Problem statement, 5W1H |

| 2. Analyze current state | Understand how things work today | Flowchart, Gemba walk, data review |

| 3. Identify root causes | Dig into why the problem is happening | 5 Whys, Fishbone diagram |

| 4. Propose solutions | Brainstorm and prioritize fixes | Team brainstorming, evaluation grid |

| 5. Create an action plan | Assign tasks, deadlines, and resources | Task list, ownership matrix |

| 6. Check if it worked | Monitor outcomes and measure success | KPIs, before/after comparisons |

| 7. Share & sustain results | Standardize and spread learning | Documentation, communication plan |

And here’s how it all comes together, one step at a time:

1. How do you define the problem clearly?

Start by writing a short, clear problem statement. Focus on facts, not feelings. Avoid blaming people or guessing what the cause is.

Good problem statements answer:

- What’s happening?

- Where and when is it happening?

- How big is the issue?

As an example: “In the last 30 days, 12% of orders were shipped late from Warehouse B.”

Define the gap between what should be happening and what is. Keep your language simple and specific: include timeframes, locations, and impact. Focus on one clear issue at a time.

Once you know the problem, you’ll want to understand exactly what’s happening right now (before you try to fix anything).

2. How do you analyze the current state?

Now it’s time to dig into what’s going on. Don’t rely on opinions. Go to the source and gather facts.

Start by mapping out the process.

Start by mapping the process: use a flowchart, value stream map, or swimlane diagram to see how things actually work. This helps spot delays, gaps, or confusion.

Next, gather data:

- Where are delays or errors happening?

- How often?

- Who’s involved?

To understand what’s happening, use tools that help you gather facts (not guesses!). These are all built into Tervene, so you can keep everything in one place (think PDCA management system).

- Gemba walk – go observe the process firsthand

- Pareto chart – focus on the biggest contributors

- 5W1H – ask who, what, when, where, why, and how

This builds a shared understanding across your team.

Here’s where you dig deeper. Let’s figure out what’s causing the problem, not just what’s on the surface.

3. How do you find the root cause?

Now you’re looking for the “why” behind the problem. Use 5 Whys: keep asking “Why?” until you get to the root cause. It’s simple but powerful.

As examples:

- Why was the order late? → The label was printed late.

- Why was the label printed late? → The printer didn’t work.

- Why didn’t it work? → It wasn’t maintained.

- Why wasn’t it maintained? → There’s no maintenance schedule.

For more complex issues, use a fishbone diagram to explore multiple possible causes.

Now that you’ve found the root cause, it’s time to brainstorm solutions that actually solve it.

4. How do you propose solutions?

Now that you know the root cause, you can brainstorm how to fix it.

Gather your team and come up with multiple ideas and implementation plans. Encourage open thinking, even if some ideas seem small or unusual. Don’t stop at the first fix.

Then, filter the ideas by asking:

- Will it fix the root cause?

- Is it realistic to implement?

- What’s the cost and impact?

You want solutions that are both effective and doable. Choose solutions that support business goals and build in team input.

This is where collaboration helps. You’ll find better answers when different perspectives come together.

A good solution needs a clear plan. Let’s break it down so everyone knows what to do—and when.

5. How do you create implementation plans?

Once you’ve picked your best solution(s), build a clear plan to make it happen. Your action plan, as a critical component of your success, should include:

- Who will do each task

- What needs to be done

- When it’s due

Break work into steps. Assign owners and set clear deadlines. Include communication steps: who needs to be informed, and how. Make it visible and trackable.

Don’t just assume the fix worked. Here’s how to measure results and adjust if needed.

6. How do you check if it worked?

Once your implementation plans are in place, you’re not done. You need to know if it actually worked. Start by defining success metrics upfront. What does “fixed” look like?

You might measure:

- Reduction in defects

- On-time delivery rate

- Customer satisfaction

- Time saved

Monitor for a few weeks or months. Be ready to adjust. Continuous improvement means learning and adapting. Be ready to adjust. A3 continuous improvement means learning from what works and what doesn’t.

If the solution works, great! Now let’s make sure it lasts, and that others can learn from it too.

7. How do you share and sustain the results (A3 continuous improvement)?

The final step is to make sure the fix lasts—and that others can learn from it:

- Share what the problem was, what you did, and what worked

- Use visuals and keep it simple

- Update procedures and training if needed

- Celebrate wins and give credit

- Ask: “What did we learn?”

You don’t have to do this all by hand. Here are some tools that make A3 faster, clearer, and easier to manage.

What tools can help in 2025?

In 2025, you don’t have to manage A3 problem-solving with sticky notes and spreadsheets. There are smart, digital tools that make the process faster, clearer, and easier to manage, especially when you’re working across teams or locations.

Here’s what can help:

1. Digital A3 templates

Skip the paper. Digital A3 forms let you create, edit, and share everything in one place. You can update in real-time, link files, and keep your thinking clear and organized.

Great for remote teams too.

2. Collaboration platforms

Use tools that let your whole team contribute, from anywhere. Platforms like Tervene are designed for structured problem-solving.

You’ll get built-in templates, checklists, and clear task assignments. Everyone stays on the same page.

3. Integrations with project management & ERP tools

Connect your A3 work with tools you already use, like project boards, ERPs, or task trackers. This keeps data flowing and reduces manual updates. It also helps tie improvement efforts directly to operations.

4. AI-based assistants

AI is no longer a buzzword. Tools now help you:

- Analyze data faster

- Spot trends

- Write clear problem statements

- Suggest root causes or corrective actions based on past issues

It’s like having an extra team member focused on insights and clarity.

Tervene brings all of this together. You’ll get a digital workspace designed for structured problem-solving, with features like Gemba walk reporting, task follow-up, and digital A3 forms. All in one platform.

Even simple tools can go wrong if misused. Here’s what to watch out for so your A3 process stays effective.

What are some common mistakes to avoid?

Even though A3 problem-solving is simple, there are a few traps that can trip you up. Knowing what to avoid will help you get better results and save time in the long run.

1. Rushing the process

It’s tempting to jump straight to implementation plans, but slow down. If you skip the thinking steps, you risk solving the wrong problem. Take the time to understand the issue before acting.

2. Skipping root cause analysis

Don’t stop at surface-level symptoms. If you don’t dig deep, the problem will come back. Use tools like the 5 Whys or a fishbone diagram to find what’s causing the issue.

3. Treating A3 as just paperwork

A3 isn’t about filling out a form—it’s about clear, structured thinking. If you treat it like a checklist, you’ll miss the value. Use it as a guide for conversations, collaboration, and learning.

Remember: the goal is to solve the problem and prevent it from happening again. When you treat A3 as a thinking tool (not just a task) you’ll get results that last.

So, ready to try A3?

Where should you start?

Ready to give A3 problem-solving from Toyota a try? Start small and keep it simple.

Pick one real problem in your organization—something that’s been nagging but not urgent. Use it as your pilot project. Choose a small team, block out time, and walk through each step of the A3 process together.

Here’s how to start:

- Choose a manageable issue

- Use a digital A3 template (Tervene is a great option)

- Involve people who know the problem best

- Focus on learning, not perfection

You don’t need to roll it out company-wide on day one. Just show how it works in action. That’s the best way to build trust and get buy-in from others. When people see real results (like fewer delays or better teamwork) they’ll want to join in.

Encourage open discussion, stay curious, and celebrate small wins.

And if you want a tool that makes it easier from day one, explore Tervene’s problem-solving tools. It’s designed to help teams solve problems, track actions, and build a culture of continuous improvement.

Start today, with one problem, one team, and a fresh way of thinking.

Accelerate problem solving with our tools

Enhance your continuous Improvement methods

Frequently Asked Questions (FAQ) About A3 Problem-Solving

A3 problem-solving is a structured, team-based method that helps identify root causes, develop effective solutions, and prevent recurring issues. Originating from Toyota, it uses a single-page (A3-sized) format to document each step—making it clear, visual, and collaborative.

In 2025’s fast-paced work environments, A3 helps teams tackle recurring or complex issues with clarity. It promotes data-driven decisions, cross-functional collaboration, and long-term solutions instead of quick fixes—making it ideal for lean and continuous improvement efforts.

Use A3 when dealing with complex problems, quality drops, recurring issues, or when multiple departments are involved. Avoid it for simple tasks, emergencies, or when a quick fix will suffice.

A small, focused team is best—typically 3–6 people. Include a team lead, someone close to the problem, and key stakeholders from relevant departments (e.g., operations, finance, customer service). Cross-functional input leads to better understanding and smarter solutions.

-

Define the problem clearly

-

Analyze the current process

-

Identify the root cause

-

Propose and evaluate solutions

-

Build an action plan

-

Check if the solution worked

-

Sustain and share the results

Digital A3 templates, collaborative platforms, and AI assistants are top tools in 2025. They streamline teamwork, automate analysis, and enhance data visibility. Integrations with project and ERP systems also reduce manual effort and improve follow-through.

-

Rushing through steps without understanding the root cause

-

Treating it as just documentation, not a thinking process

-

Skipping team input or failing to involve key voices

Taking time to think, involve others, and focus on the real issue is key to success.

Start small: pick one persistent issue, involve a small team, and walk through the A3 process using a digital template. Focus on learning and improvement—not perfection. As confidence grows, scale it to other areas.