Top 12 Lean Manufacturing Tools You Should Master in 2026

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | October 10, 2025 |

| Read time: | 19 min |

- Explore 12 proven lean tools, from 5S and Kanban to Poka-yoke and TPM, and learn when and how to apply each one.

- See how these methods improve flow, quality, and teamwork, so you can cut costs, boost efficiency, and keep customers happy.

- Get practical tips to turn lean knowledge into action, starting small, building momentum, and creating a culture of continuous improvement.

Lean manufacturing is all about creating more value with less waste. It helps teams improve processes, cut unnecessary steps, and deliver better results faster. While it first took off in factories, lean thinking now works in almost every industry: from manufacturing to healthcare to tech.

So, why are lean tools still important in 2025?

Because businesses face constant pressure to do more with less. Markets shift. Customer expectations rise. Technology changes fast. Lean tools help you stay agile, efficient, and focused on what really matters.

When you master lean tools, you’ll:

- Solve problems faster

- Improve team collaboration

- Reduce costs and waste

- Increase customer satisfaction

- Build a culture of continuous improvement

This guide is here to help you do exactly that.

You’ll discover lean manufacturing tools worth mastering in 2025. Not all tools fit every situation, so we’ll help you choose the right ones for your needs.

More than that, you’ll get a clear path to mastery. You’ll know what each tool does, when to use it, and how to apply it in your work.

Lean can seem complex at first. Our goal is to make it simple, practical, and easy to apply, so you can start seeing results right away. Let’s get started.

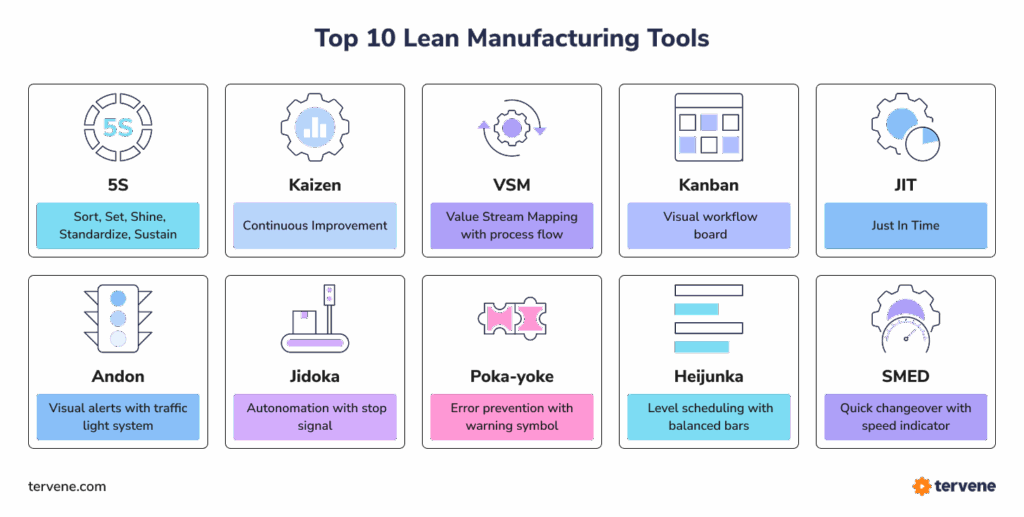

What are the top lean manufacturing tools and techniques you should know? 12 examples

So, what lean tools should you focus on in 2025? That’s exactly what this section will cover. Before we dive in, here’s a quick overview of the 12 tools we’ll cover.

| Tool | What it helps companies do |

| 5S | Organize and clean your workspace |

| Value Stream Mapping (VSM) | See and improve workflow |

| Kaizen | Drive daily continuous improvement |

| Kanban | Visualize and manage workflow |

| Poka yoke | Prevent mistakes before they happen |

| Just-in-time (JIT) | Reduce inventory and produce on demand |

| Jidoka | Build quality into the manufacturing process |

| Standardized Work | Improve consistency and training |

| Takt Time | Balance production to customer demand |

| Hoshin Kanri | Align goals with daily actions |

| Heijunka | Level and smooth production flow |

| Total Productive Maintenance (TPM) | Reduce equipment downtime |

And here are the top 12 lean manufacturing tools in details.

What are 5S tools, and why are they the foundation of a lean system?

If you’re new to lean, 5S is the perfect place to start. It’s simple, practical, and gives you quick wins. More importantly, it builds the habits and mindset that drive lean success.

5S is a lean system for creating an organized, efficient, and safe workspace. It stands for:

- Sort → get rid of what you don’t need

- Set in order → arrange what’s left so everything has a place

- Shine → clean the space so it’s easy to spot problems

- Standardize → create simple routines so everything stays organized

- Sustain → build habits so the system lasts over time

When your workplace is clutter-free and well-organized, employees waste less time. It’s easier to spot issues. Safety improves. Morale goes up. And lean practices become much easier to apply.

Here are some practical ways to start using 5S:

- Walk the workspace and tag anything you don’t need (red-tagging works great)

- Create clear labels and visual guides so tools and materials are easy to find

- Schedule regular cleaning, and treat it as a key part of the job

- Develop simple checklists to keep everything consistent

- Hold quick 5S audits to make sure good habits stick

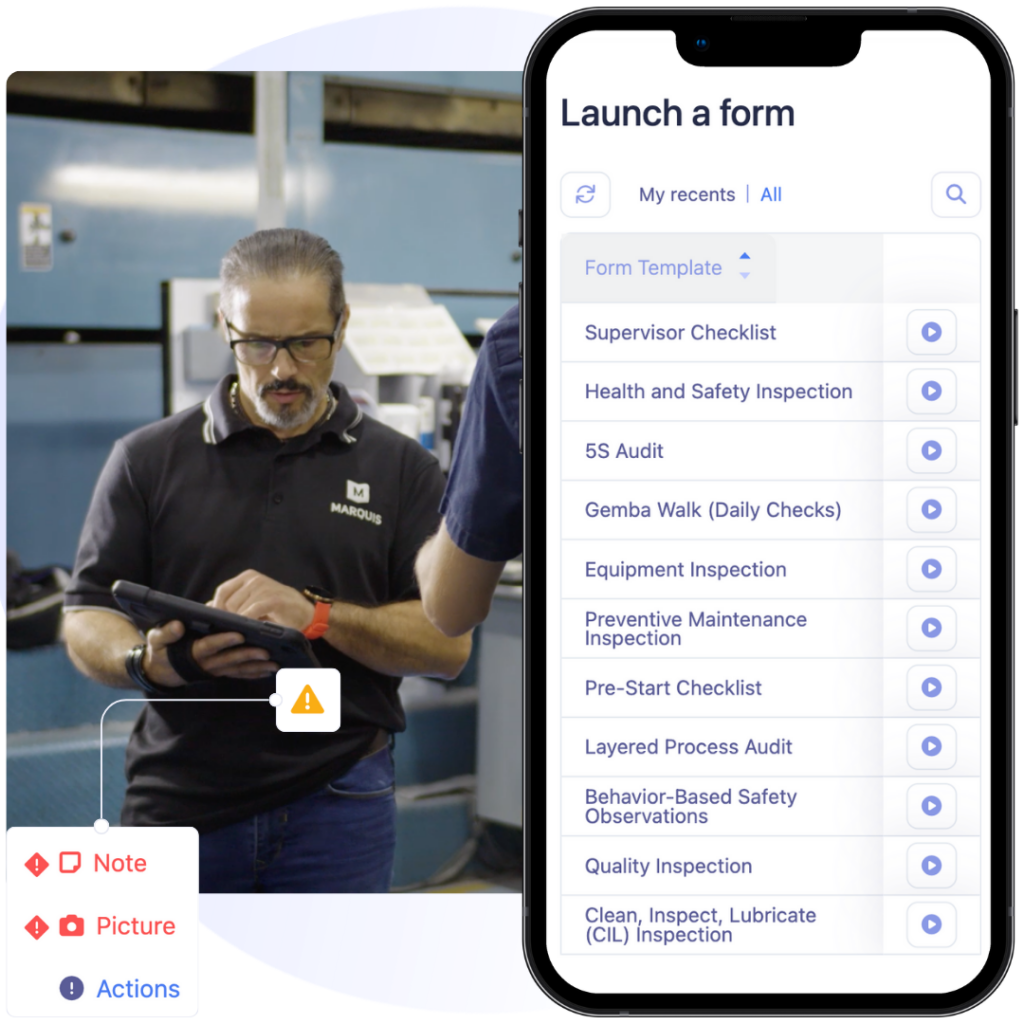

Tervene, as your lean management software, can help by giving you digital checklists and audit tools that make 5S routines easier to manage and follow.

And remember: start small. Focus on one area first. As you see the benefits, you’ll naturally want to expand.

How does Value Stream Mapping work?

Value Stream Mapping (VSM) helps companies see how work flows through their process, and where they get stuck. It’s one of the most effective lean tools for spotting waste and finding ways to improve flow.

Here’s the idea: You create a simple visual map of your manufacturing process, step by step. You show how materials, information, and tasks move from start to finish. Along the way, you highlight where delays, bottlenecks, and waste occur.

When you can see the process, it’s much easier to improve it.

You’ll use VSM to:

- Identify waste → spot unnecessary steps, delays, and rework

- Improve flow → make work move faster and smoother

- Visualize the process → get everyone on the same page about how things really work

A few practical steps to get started:

- Pick a product or service to map

- Walk through the entire process (don’t rely on guesswork)

- Draw each step on a big sheet of paper or digital tool

- Add key info: times, delays, inventory, handoffs

- Highlight areas of waste or inefficiency

- Brainstorm ways to streamline the process

You don’t need fancy software: a whiteboard or paper works just fine to start. You can map your processes digitally in Tervene, so your team can update and share improvements in real-time.

Once your team sees the process clearly, they’ll often suggest simple fixes right away. Over time, VSM helps you create smoother, faster, more efficient operations.

Industry leaders leverage Tervene to implement lean manufacturing tools

What is Kaizen, and how can you practice it daily? Continuous improvement tools

Kaizen means continuous improvement. It’s one of the core ideas behind lean manufacturing and one of the easiest to start using every day.

The basic concept is simple: You and your team look for small ways to improve the work, every day.

You don’t need big projects or fancy equipment. You focus on small changes that, over time, make a big impact.

Kaizen helps you build a continuous improvement culture, where everyone’s always looking for ways to do things better.

When you practice kaizen daily, you’ll:

- Solve problems faster

- Boost efficiency

- Make work easier and safer, reduce human error

- Engage your team in improvement

- Deliver better results for customers

Here are some easy ways to practice kaizen:

| Activity | Example |

| Ask “What can we improve today?” | Morning team huddle |

| Identify a small change to test | Repositioning tools for better reach |

| Share one improvement with the team | Post on improvement board |

| Log ideas for future improvements | Kaizen notebook or Tervene app |

| Recognize team contributions | Quick shout-out in daily meeting |

Also, you can use Tervene to track and share daily kaizen ideas, so improvements stay visible and momentum builds. And remember: it’s about steady progress, not perfection.

How can Kanban help you manage workflow?

Kanban is a simple, visual way to manage work. It helps you see what’s being done, what’s waiting, and what’s next, all at a glance.

The heart of Kanban lead methodology is visual scheduling. You use a board (physical or digital) with columns that show different stages of work, like To Do, In Progress, and Done. Each task is shown on a card that moves across the board as work progresses.

This makes the entire workflow visible to everyone. No guessing. No confusion. Pure lean productivity.

Kanban also helps you limit work-in-progress (WIP). This is key. When too much work is started at once, progress slows down. Employees get stuck multitasking or waiting.

By setting WIP limits, you encourage the team to finish tasks before starting new ones. This keeps the flow steady and smooth. You’ll see improvements like:

- Faster delivery times

- Fewer bottlenecks

- Less stress for the team

- Higher quality results

Here’s how to start using Kanban:

- Set up a simple board with key stages of your workflow

- Add tasks as cards and move them as work progresses

- Set WIP limits for “In Progress” work

- Review the board regularly to spot and fix flow issues

- Adjust your plan and improve as you go

Kanban helps you improve efficiency without adding complexity. And digital Kanban boards in Tervene can help you manage work visually, especially across multiple teams or locations. It’s flexible, easy to learn, and works for any team.

Once you try it, you’ll wonder how you ever managed without it.

Eliminate hidden inefficiencies with Tervene’s tools

What is Poka yoke and how does it prevent errors?

Poka yoke means mistake-proofing. It’s a lean tool that helps you design processes so that it’s almost impossible to make certain types of errors.

Instead of fixing mistakes after they happen, poka yoke helps you prevent them before they occur.

The idea is simple: build in checks, guides, or failsafes so that tasks can only be done the right way. This reduces defects, saves time, and improves quality, all without adding extra inspection work.

Here are a few common mistake-proofing techniques:

- Physical guides that ensure parts can only be installed the correct way

- Color coding to match components or materials

- Sensors that detect missing parts

- Alarms that alert operators when something’s out of place

- Fixtures that prevent incorrect assembly

You’ll see these in action in real factories every day:

- A jig that only holds a part if it’s oriented correctly

- A connector that only fits one way, avoiding cross-wiring

- Weight sensors that stop the line if a component is missing

- Assembly tools that won’t release unless torque is within spec

Poka yoke doesn’t have to be high-tech. Often, the simplest solutions are the best.

When you use poka yoke, you’ll:

- Cut down on rework

- Save time

- Improve safety

- Increase product quality for organizations

It’s one of the easiest ways to drive big improvements in reliability, and it’s a must-have tool in any lean environment.

How do you apply Just-in-time (JIT)?

Just-in-time (JIT) is all about producing only what’s needed (when it’s needed!) and in the right amount.

Instead of building up large stockpiles of parts or products, you produce items based on actual demand. This helps you avoid the costs and risks of excess inventory.

When you apply JIT, you’ll:

- Free up space

- Reduce inventory waste

- Cut storage costs

- Respond faster to changes in demand

- Improve cash flow

Here’s how to start using JIT:

| Step | What to focus on |

| Understand demand | Analyze customer order patterns |

| Plan and align production with demand | Produce only what’s needed |

| Work with suppliers | Order smaller, more frequent batches |

| Shorten setup/changeover time | Reduce downtime between products |

| Use visual triggers | Kanban cards or digital signals |

Remember: JIT as a lead methodology isn’t about cutting inventory to zero overnight. It’s about finding the right balance so you stay lean without running out.

Done well, JIT will help you work more efficiently, cut waste, and stay flexible in a fast-changing world.

What is Jidoka and why is built-in quality important?

Jidoka is a lean methodology that means “built-in quality.” The idea is simple: catch problems early (right when they happen), instead of finding them later.

When you detect defects early, you avoid passing bad work down the line. That saves time, cuts rework, and protects your customers from poor-quality products.

Jidoka also means empowering workers to stop production if they spot an issue. This is key. Instead of letting problems pile up, your team takes action right away.

When you build jidoka into your manufacturing process, you’ll:

- Improve product quality

- Reduce waste and rework

- Solve problems faster

- Build trust and ownership within your team

Here’s how you can apply jidoka:

- Install sensors that stop machines if a defect is detected

- Train workers to pause production if something looks wrong

- Design processes so it’s easy to spot problems (visual cues help)

- Encourage a “quality first” mindset, where stopping for quality is always supported

For example:

- On an assembly line, a worker pulls a cord (andon) to stop the line if a defect is found

- A machine automatically halts if a measurement goes out of tolerance

- Visual guides make incorrect parts or assemblies obvious

When you focus on built-in quality, you prevent issues instead of fixing them later. This leads to smoother operations and happier customers.

Jidoka is one of the best ways to create a culture of quality, and it works in any type of manufacturing.

How can standardized work bring lean productivity?

Standardized work is one of the most practical tools in lean manufacturing. It helps you make sure the best way of doing a job is captured, taught, and followed, every time.

At its core, it’s about documenting best practices. You take what works best (the safest, fastest, most reliable method) and write it down in a simple, clear format. This becomes the standard for how the work should be done.

When you have good standards in place, you’ll:

- Improve consistency

- Reduce mistakes

- Make training easier

- Support continuous improvement

Another key benefit is training for repeatability. With standardized work, new team members can quickly learn the right way to do the job. Experienced workers can stay sharp and consistent. Everyone knows what’s expected, which keeps quality high.

Here’s how to start using standardized work:

- Watch how the best work is done. Talk with experienced team members

- Write simple, clear instructions (with photos or diagrams if needed)

- Train everyone using the same standards

- Post the standards where the work happens; easy to see and use

- Keep improving: update the standards when better ways are found

Tervene makes it easy to document standardized work and share updates instantly with your team If you want reliable results, day after day, standardized work with Tervene is a must.

What is takt time and how does it balance production?

Takt time is one of the simplest ways to bring balance to your production process. It helps you set the right pace, based on what your customers actually need.

The word takt comes from the German word for “rhythm” or “beat.” In lean terms, it means matching the pace of production to customer demand.

You figure out how often you need to produce a unit to meet demand, and then adjust your workflow to match that rhythm. Not too fast, not too slow.

When you work to takt time, you’ll:

- Reduce overproduction

- Avoid bottlenecks

- Keep production flowing smoothly

- Deliver on time

You’ll also be able to identify bottlenecks faster. If one step can’t keep up with takt time, that’s your signal to take action, maybe by improving flow, fixing equipment, or adding resources.

Here’s how to apply takt time:

- Calculate takt time by dividing available production time by customer demand

- Share that takt time with the team

- Adjust the workflow to meet that pace

- Monitor performance and flow, KPIs

- Make improvements where needed to keep pace steady

For example, if customers need 240 units per shift, and you have 480 minutes to work, your takt time is 2 minutes per unit. Now the team knows exactly how fast each unit should move through the process.

Takt time helps you run lean, smooth, and in sync with your customers, which is exactly where you want to be.

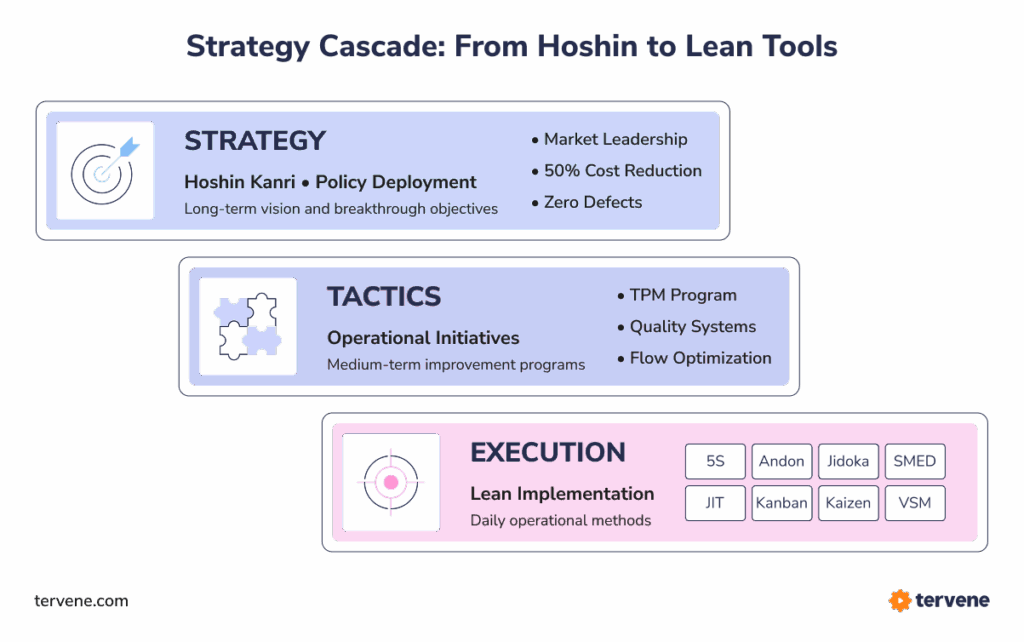

How does Hoshin Kanri align your goals?

Hoshin Kanri is a simple but powerful way to connect strategy with daily work. It helps make sure everyone in the organization is moving in the same direction toward the goals that matter most.

Think of it like this: you’ve got big-picture objectives. But unless those goals shape what happens on the factory floor every day, they stay just words on paper. Hoshin kanri bridges that gap.

You’ll use it to:

- Translate long-term goals into clear, actionable plans

- Align teams across all levels

- Stay focused on priorities and your plan

- Track progress and adjust along the way

Here’s how it works in practice:

- Define key goals (for the year, quarter, or longer)

- Break those goals into smaller targets for departments and teams

- Identify the actions needed to hit each target and KPIs

- Communicate the plan clearly, so everyone knows their role

- Check in regularly, review progress, and make adjustments

Hoshin Kanri helps you avoid scattershot efforts. You’ll focus energy where it counts, keep teams aligned, and make steady progress on your most important goals.

What is Heijunka and how does it smooth production flow?

Heijunka is all about leveling demand so your production runs smoothly, without the ups and downs that cause problems.

In most businesses, customer orders don’t come in a steady stream. Some days are busy. Some days are slow. If you try to match production exactly to those swings, it puts a lot of stress on your systems and your employees.

Heijunka helps you even things out. You plan and spread work more evenly over time, so you can handle demand without rushing or scrambling.

When you apply heijunka, you’ll:

- Reduce stress on systems and equipment

- Make workloads more balanced for your team

- Avoid last-minute firefighting

- Improve flow and efficiency, overall equipment effectiveness

- Deliver more consistently to customers

Here’s how to get started:

- Collect data and analyze customer demand patterns

- Break larger orders into smaller, regular batches

- Build a mixed schedule: producing different products in small batches across the day or week

- Adjust setup processes so switching between products is easy

- Monitor and fine-tune the schedule as demand shifts

For example, instead of producing 1,000 units of Product A one week and 1,000 units of Product B the next, you’d produce a smaller mix of both products each day.

This steady rhythm reduces stress on your systems and makes it easier to keep quality high. Over time, you’ll see smoother production, happier teams, and more reliable delivery to customers.

How can Total Productive Maintenance (TPM) reduce downtime?

Total productive maintenance helps you keep equipment running smoothly, so you can avoid unplanned downtime.

The key idea is simple: involve everyone in equipment care, not just the maintenance team. Operators, supervisors, and maintenance staff all work together to keep machines in top shape.

Instead of waiting for things to break, you take a proactive approach. You spot issues early, handle small problems before they turn into big ones, and keep everything running at peak performance.

When you apply TPM, you’ll:

- Reduce unplanned downtime

- Extend equipment life

- Maximize asset efficiency

- Improve safety

- Boost product quality

Here’s how to get started:

- Train operators to handle basic maintenance (cleaning, inspection, lubrication)

- Create simple daily checklists with KPIs

- Encourage teams to report small problems right away

- Schedule regular preventive maintenance

- Track equipment performance to spot trends

- Celebrate wins, because every improvement helps

By involving everyone in equipment care, you’ll build a culture of shared responsibility. Machines won’t just “belong” to maintenance anymore: the whole team will help keep them running well.

When equipment runs reliably, everything else gets easier. You’ll see smoother flow, fewer delays, and better results across the board.

TPM is one of the most practical ways to maximize asset efficiency and a must-have for any lean manufacturing environment.

How do you choose which lean methods to master first?

With so many lean tools out there, it can feel a little overwhelming at first. But you don’t have to master everything at once. The key is to start where it matters most.

First, take time to assess your current processes. Walk the floor. Talk to your team. Look at where problems tend to pop up. Maybe it’s downtime, quality issues, or inventory piling up. This gives you a clearer picture of where lean tools can help.

Next, look for quick wins. Which tools could give you fast, visible improvements? Small wins build momentum and get your team engaged.

For example, if the workplace is disorganized, start with 5S. If flow is slow, try value stream mapping. If quality is inconsistent, look at poka yoke or standardized work.

At the same time, make sure you’re aligning with business goals. What’s most important right now: cutting costs, improving delivery, boosting quality? Choose tools that will help you get there.

Here’s a simple way to decide:

- Assess where the biggest problems or opportunities are

- Identify tools that can deliver quick wins

- Prioritize tools that align with key business goals

- Start small and master one tool at a time

- Build on your success and expand from there

You’ll learn faster, get better results, and keep your lean journey moving forward, step by step. And tools like Tervene can really help here, giving you one place to manage lean tools and track progress.

Turning these principles of lean management into manufacturing action

Learning lean tools is a great start, but the real value comes when you put them into action. And remember: mastering lean tools is a journey. You don’t have to do everything at once.

Start with what makes sense for you. Look at your current challenges. Choose one or two tools that can help right away. Build from there.

As you go, you’ll discover that small, consistent efforts lead to big results. Every plan and improvement, no matter how small, moves you closer to your goals.

And don’t be afraid to bring technology into the mix. Digital lean tools can really help, making it easier to track progress, share information, and stay on top of improvement efforts.

To help you turn lean knowledge into action, here’s a simple plan to follow. You can revisit it anytime to stay on track.

| Action step | Why it matters |

| Pick 1-2 tools to focus on first | Keeps things simple and doable |

| Walk the floor and observe | Helps you spot real opportunities |

| Involve your team from the start | Builds engagement and ownership |

| Plan and track small improvements daily | Creates momentum |

| Share results and celebrate wins | Keeps the team motivated |

| Adjust and improve as you go | Supports continuous progress |

| Use digital tools like Tervene | Makes tracking and scaling easier |

Lean management software

One great option to explore is Tervene. It’s a digital platform designed to support lean practices on the shop floor. You can:

- Standardize processes

- Plan and run daily management routines

- Track actions and improvements

- Drive better communication between teams

Trying Tervene can make your lean journey smoother, especially if you want to scale lean across multiple teams or sites.

Most importantly, keep going. Lean is a mindset and a way of working. The more you practice, the more it becomes part of your culture.

So pick a tool, plan and take action, and keep improving. You’re on the right path, and the results will follow.

Implement a Lean Management System

Build a culture of continuous improvement with tools that strengthen operational control, accountability, and problem‑solving.

Industry leaders use Tervene’s Lean manufacturing tools to eliminate waste, reduce process variation, and deliver more value at every level of their organization.

Discover Tervene’s Lean manufacturing tools .wp-block-media-text li { padding-bottom:5px }

Lean Manufacturing FAQ

Lean manufacturing is a process improvement approach that focuses on creating more value for customers with fewer resources. It aims to eliminate waste, improve efficiency, and build a culture of continuous improvement.

Lean tools help companies stay competitive in fast-changing markets by reducing costs, increasing productivity, improving product quality, and responding quickly to customer needs. In 2025, lean methods remain essential as technology and customer expectations evolve rapidly.

Here are 12 lean tools worth mastering:

-

5S: Workplace organization and standardization

-

Value Stream Mapping: Visualizing and improving workflows

-

Kaizen: Daily continuous improvement

-

Kanban: Visual workflow management

-

Poka-yoke: Mistake-proofing processes

-

Just-in-Time (JIT): Producing only what’s needed

-

Jidoka: Built-in quality control

-

Standardized Work: Documenting best practices

-

Takt Time: Balancing production with demand

-

Hoshin Kanri: Aligning strategy with daily actions

-

Heijunka: Leveling production flow

-

Total Productive Maintenance (TPM): Minimizing equipment downtime

Begin by:

-

Assessing where your biggest problems or inefficiencies are.

-

Picking one or two tools that can deliver quick, visible improvements.

-

Prioritizing tools aligned with your business goals (e.g., reducing defects, improving delivery times).

-

Starting small and expanding as your team gains confidence.

5S is a simple, foundational lean system to organize and maintain a clean, efficient workspace. It stands for:

-

Sort (remove what’s unnecessary)

-

Set in Order (arrange items clearly)

-

Shine (clean the area)

-

Standardize (establish routines)

-

Sustain (keep habits going)

Starting with 5S helps build the mindset and discipline that supports all other lean practices.

Kanban uses visual boards and cards to track work as it moves through stages like To Do, In Progress, and Done. This transparency:

-

Reduces bottlenecks

-

Limits work-in-progress

-

Improves delivery speed

-

Keeps teams aligned

Poka-yoke means “mistake-proofing.” It involves designing processes, tools, or systems so errors are automatically prevented or made obvious. Examples include:

-

Color coding parts

-

Physical guides that prevent misassembly

-

Sensors that detect missing components

Sustaining lean practices requires:

-

Standardizing work procedures

-

Regularly training teams

-

Tracking results and progress

-

Celebrating small wins

-

Continuously refining processes

Using visual management and daily huddles can help keep momentum going.

Lean tools improve customer satisfaction by:

-

Delivering consistent quality

-

Reducing lead times

-

Minimizing errors and defects

-

Creating smoother, faster processes

When your operations run efficiently, customers get better products faster.