Lean Management System Explained: From Basics to Performance

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | December 10, 2025 |

| Read time: | 9 mins |

- An LMS uses digital tools to sustain continuous improvement through standardized practices.

- Implementing an LMS boosts efficiency, reduces waste, and enhances employee engagement.

- Successful LMS adoption requires a company-wide commitment and digital tools to streamline the transition and foster continuous improvement.

A Lean Management System is a technical and organizational solution for structuring continuous improvement in your organization. Lean Management software provides the framework for maintaining a steady, sustainable pace toward Lean’s long-term objectives. Here are explanations about the benefits of Lean Management Systems and our advice for implementing them.

What is a Lean Management System?

A Lean Management System (LMS) is a methodological framework for fostering a lean culture within an organization. It helps teams stay aligned around clear objectives and remain consistent in applying improvements as part of everyday work.

An LMS for an organization is the equivalent of a computer’s operating system. It involves digital solutions to help organizations apply the core principles of Lean, which we’ll break down shortly.

The meaning of lean in business and manufacturing

Lean manufacturing is an entire shift in mindset and philosophy. At its core, it’s about creating the most customer value with the least waste. The method initially gained traction in automotive production, but has now become the backbone for efficiency across nearly every industry.

What defines Lean? It’s about staying obsessed with the customer, spotting waste where others don’t see it or miss it, and, most importantly, giving frontline teams the room to question how things are done and the freedom to contribute solutions to the issues.

In day-to-day work, Lean helps companies identify friction and remove it before it ever becomes a problem. It’s the reason why teams stop doing three extra steps that no one can justify. And it’s why the entire workflow feels smoother, faster, and a lot less frustrating without cutting corners or sacrificing quality.

Industry leaders leverage Tervene to implement lean manufacturing tools

The 5 principles of lean manufacturing and production

Lean is built on five principles, and when embedded in daily routines, they can fundamentally transform how an organization operates.

1. Define lean value and operations

Everything starts here. What does the customer actually care about? Not what you think is essential. But what they truly value. Getting clear on this avoids waste and aligns everyone on what matters most.

2. Map the value stream

Once the end goal is clearly defined, businesses can trace how the entire work flows across their team, identifying every step in every process, and cutting what doesn’t add value. This step is brutal (in a good way), and it’s where most companies realize how much bloat has piled up over time.

3. Create lean workflows

Lean companies don’t operate in fits and starts. They aim for a smooth, consistent flow of work that minimizes waiting, bottlenecks, and handoff chaos. When flow works, everything speeds up. Without burning people out.

4. Establish pull

Instead of pushing work downstream and hoping for the best, Lean systems focus on pull. Doing work only when there’s actual demand. It’s smarter, leaner, and helps teams stay responsive.

5. Pursue perfection

No Lean journey is ever truly “complete.” Teams are encouraged to spot issues, share ideas, and keep improving daily. Continuous improvement is a philosophy that keeps the system alive and evolving.

Core Methods of Lean Manufacturing

That being said, technology plays a crucial role in structuring a lean organization. Here are the critical elements for performance and improvement management:

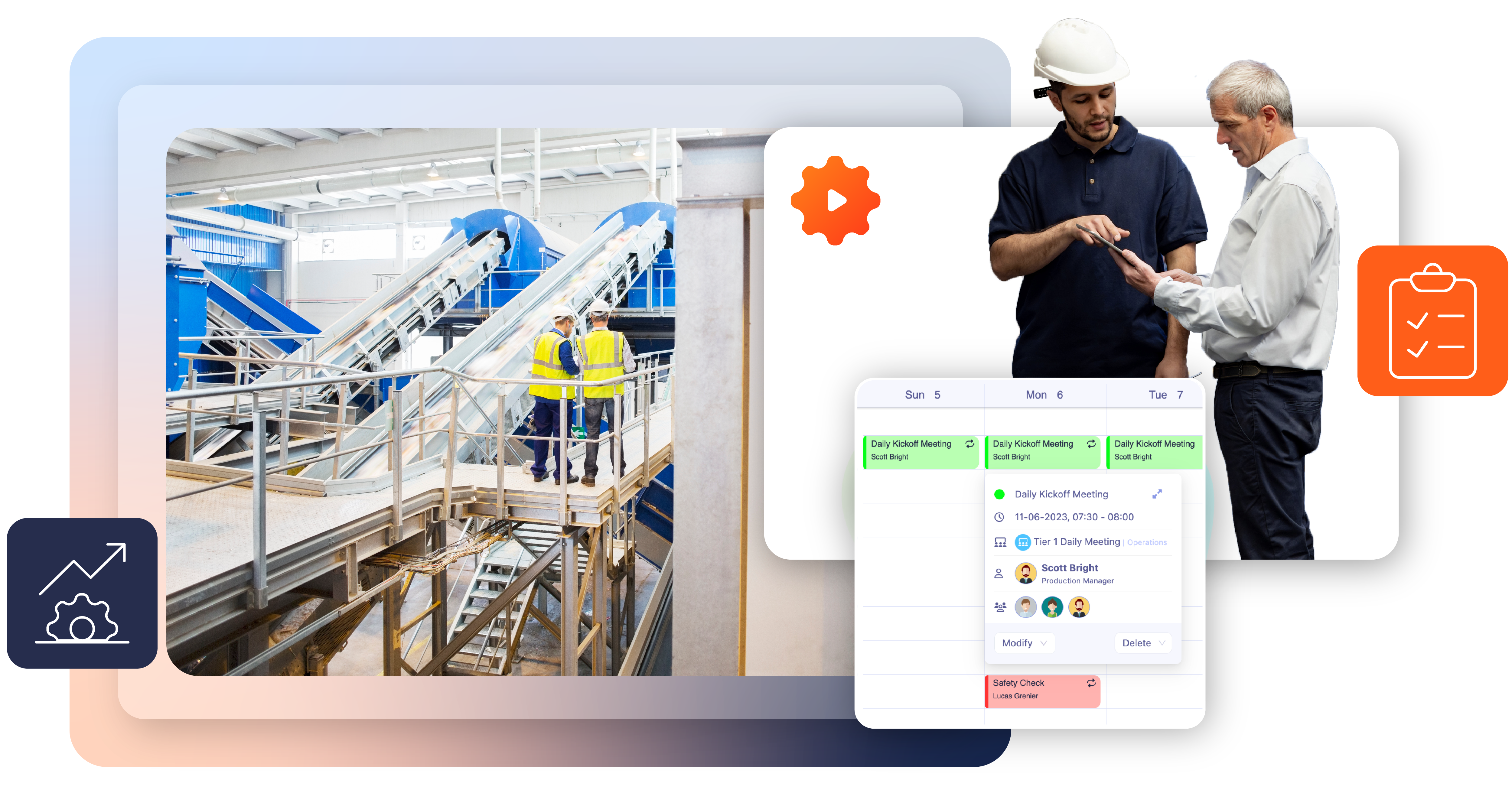

Leader Standard Work (LSW)

Leader Standard Work is a structured approach to standardize routines, skills, and tools. LSW’s objective is to eliminate process variation and boost efficiency. It contributes to Lean Daily Management, which focuses on daily operations (including Gemba Walks, where leaders go to the front lines) to ensure alignment with goals and continuous improvement.

Visual Management

Visual Management is critical to Lean because it enables clear communication and breaks complex data into actionable insights. Such methods and tools include SQCDP (Safety, Quality, Cost, Delivery, and People) indicators and Kanban boards with an overview of tasks and workflows.

Digital solutions include personalized and automated reports with dashboards embedded in collaboration platforms (through iFrame).

The Japanese 5S lean methodology and initiative

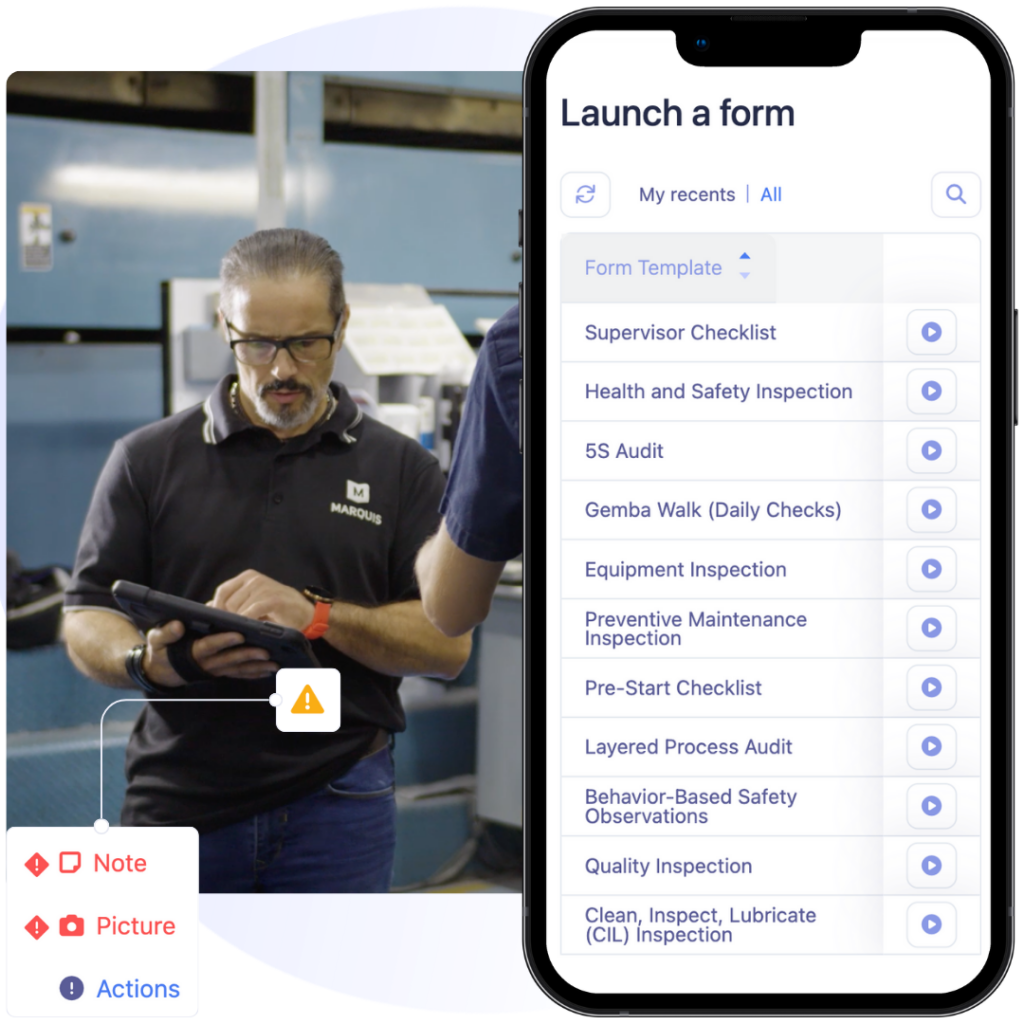

The Japanese 5S Lean Methodology aims to create a more organized and productive workspace. In English, the 5S stands for Sort, Set in Order, Shine, Standardize, and Sustain. In addition, a 6Th S emphasizes the importance of Safety.

For instance, with Tervene’s software, you can digitize your 5S audit checklist, build custom checklists, track actions, and generate reports.

Just-in-Time (JIT) manufacturing

Just-in-Time (JIT) is a basic lean production method that tries to make only what is needed, when it is needed, and in the right amount. JIT eliminates unnecessary stockpiling and overproduction waste, reducing excess inventory, shortening lead times, and improving cash flow.

Within a Lean Management System, JIT is supported by digital scheduling, real-time data visibility, and synchronized planning across teams and suppliers, helping businesses effectively respond to customer needs and reduce waste at every stage of the supply chain.

Continuous improvement

Continuous Improvement is the ultimate goal of a lean strategy. Project management and task-tracking software make it easier to follow continuous improvement methodologies such as PDCA (Plan-Do-Check-Act) cycles and Kaizen.

Standardize and structure lean manufacturing processes with Tervene’s tools

Implementing an LMS model

Implementing an LMS requires a company-wide change, but digital Lean manufacturing tools can help fast-track it. In fact, Lean Daily Management (LDM) systems can be set up in 4 to 8 weeks to help build Lean habits and manage continuous improvement and daily operations in the workplace. Managers also need a framework to standardize their practices, prioritize objectives, and support their teams.

With Tervene’s Leader Standard Work software, team leaders, supervisors, and managers can define and use templates to execute daily, weekly, and monthly tasks. Most importantly, LSW fosters proactive supervision and control over daily operations. With structured Gemba Walks, periodic inspections (Health, Environment, Safety, and 5S audits), and daily checks, managers can progressively move away from firefighting mode and adopt a more proactive approach.

How leading companies roll out an LMS

There’s no one-size-fits-all approach, but most successful Lean transformations follow a similar structure. Here’s how many industry leaders implement their systems:

- Audit your current state: Start by identifying pain points in your existing business processes. Especially anything that slows down operations, causes waste, or creates misalignment between teams.

- Set clear improvement goals: Whether it’s cutting lead times, improving cross-team accountability, or reducing defects, define what success looks like in the early stages — and make it measurable.

- Choose the right platform: Select tools that go beyond simply spreadsheets and whiteboards. Look for a reliable digital system that supports audits, Gemba Walks, follow-ups, and seamless employee collaboration.

- Standardize workflows and routines: Roll out Leader Standard Work templates, checklists, and review cadences to build structure and consistency into your daily operations.

- Train teams and empower leaders: A system only works if people actually use it. Therefore, provide managers with the proper training and ownership they need to drive change effectively from the front line.

- Track performance and adjust continuously: Use dashboards and performance reviews to measure progress across key activities, surface recurring issues, and fine-tune the entire Lean system over time.

By following this structured rollout, companies can truly integrate Lean philosophy into their operations and build an authentic culture of continuous improvement, rather than just a collection of tools.

It’s also how they strengthen operational control, increase accountability, and make problem-solving part of the everyday rhythm.

That’s why industry leaders across manufacturing, logistics, and services rely on Tervene’s Lean Management tools. With the right system in place, teams work smarter, together.

Benefits of implementing an LMS

Lean Management Systems help companies streamline processes through standardized work and digitized processes. They also increase efficiency and productivity, reduce waste, and improve quality and customer satisfaction, providing companies with countless tangible benefits.

For example, with Tervene’s Lean Daily Management System, our customers are 58% faster at performing audits and addressing nonconformances. They also identified and solved 3.3 more issues in the first six months.

Moreover, an LMS enhances employee morale and engagement. This human factor is crucial as many lean projects lose momentum after initial bursts of improvement. Over time, teams can lose motivation and resist change because they get lost in the daily hustle and bustle and lack a long-term perspective. In fact, between 50% to 95% of lean projects fail because companies rely on tools and techniques without fully embracing the continuous improvement goal at the heart of lean.

A unified LMS facilitates the data collection, analysis, and communication teams need to measure their progress. With this shared structure and culture, teams can embrace change and feel empowered to seek opportunities for continuous improvement.

Challenges of traditional Lean Management approaches

Resistance to change can stifle Lean initiatives. Companies accustomed to traditional paper-based systems often need to pay closer attention to how their tried-and-true systems are time-consuming, inefficient, and error-prone. Additionally, they undervalue the cost of maintaining a paper trail and face compliance risks.

The bigger issue? These systems hide problems. If your audits live on paper, no one sees the gaps until it’s too late. If your meetings happen without structure, issues fall through the cracks. And when everyone has their own “version” of the process, improvement turns into guesswork.

It’s not that these teams don’t care. It’s that they’re flying blind. Without a shared, visible structure, even the most well-intentioned Lean efforts lose momentum. Fixing this isn’t just about going digital. It’s about making your business processes transparent enough to actually manage.

Go digital with your LMS

Bringing Lean principles to life starts with the right systems. While Lean thinking sets the direction, a digital LMS gives your teams the structure, visibility, and consistency to follow through.

With Tervene’s management software, you benefit from standardized, digitized practices and stronger collaboration across teams, helping managers and frontline teams stay aligned with priorities and keep improvement efforts on track.

Implementing a Lean Management System can take just a few weeks. But to make it stick, you need a 360° approach, one that connects leadership, operations, and frontline teams.

That’s why leaders worldwide trust Tervene to help them turn strategy into everyday action and take complete control of their continuous improvement journey.

Implement a Lean Management System

Take control of your operations. Build a culture that delivers.

- Strengthen accountability and problem-solving across your team

- Eliminate waste and reduce variation in your processes

- Drive measurable value at every level of your organization

FAQ

A lean management system (LMS) is a structured framework that helps organizations apply and sustain Lean principles, improve performance, and eliminate waste through standardized, continuous improvement practices.

Lean manufacturing is a methodology focused on delivering the most value with the least resources by reducing waste, improving flow, and continuously optimizing every part of the production process.

The core principles include: defining customer value, mapping the value stream, creating flow, and establishing pull, all aimed at achieving continuous improvement.

Sort, Set in Order, Shine, Standardize, and Sustain. Five steps to create an organized, efficient, and safe work environment.

Tervene’s platform is a real-world example, offering digital tools that help leaders standardize processes, track performance, and lead continuous improvement initiatives.

JIT is a Lean method that produces only what’s needed, when it’s needed, in the exact amount required. Reducing inventory, waste, and lead times.