Manufacturing Process Audits: Types, Examples & Complete Guide

| Audience: | Manufacturing and Healthcare Executives, Lean Management and Continuous Improvement Professionals, Operational Leaders and Safety Officers |

| Last updated: | October 3, 2025 |

| Read time: | 15 min |

- Four main types of audits: system, process, product, and compliance, each targeting a different area of performance.

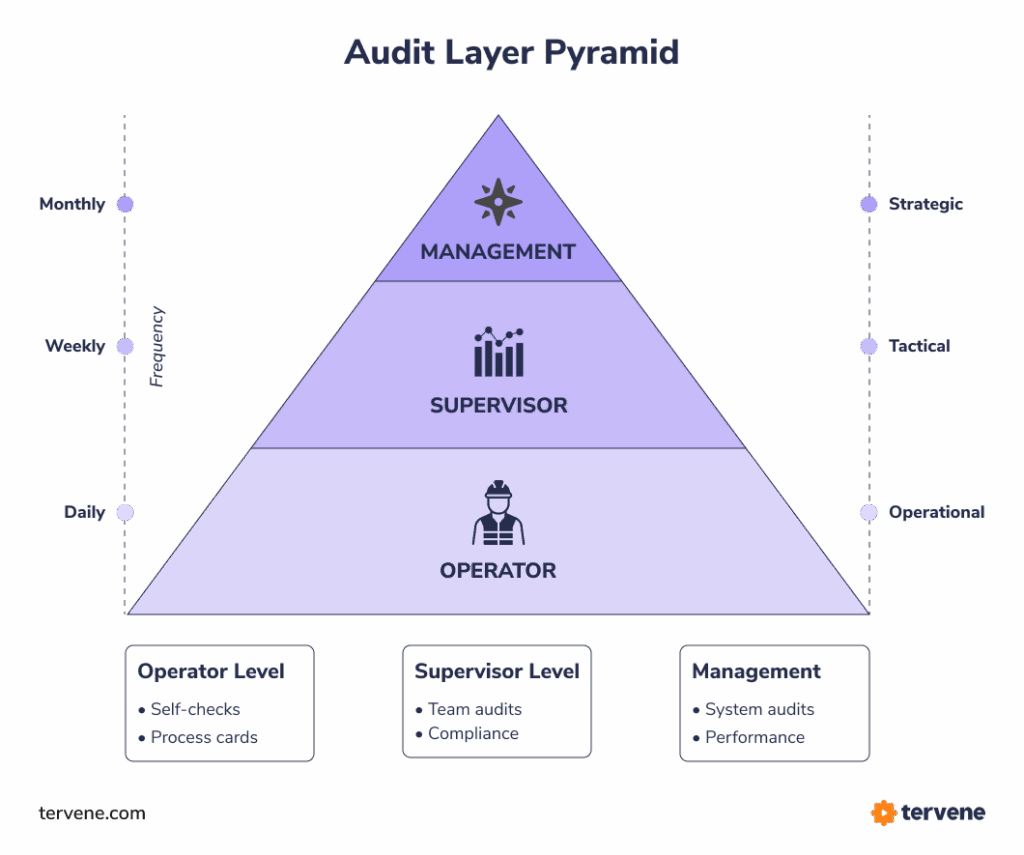

- Layered Process Audits (LPAs): involve operators, supervisors, and managers at different frequencies to maintain discipline and prevent defects.

- Audit checklists and follow-ups: structured criteria, clear documentation, and corrective actions ensure findings translate into real improvements.

No manufacturing plant can run smoothly at all times. Issues will always emerge. The question is how early a business can detect them.

Imagine an operator misunderstanding instructions at the beginning of a shift or equipment slowly drifting out of calibration with nobody noticing. These minor issues can quickly escalate into costly recalls, accidents, or lost productivity. Wouldn’t it be best to detect those issues on the spot, before they snowball into something serious?

This is where manufacturing process audits come into play. Instead of waiting until issues arise at the final inspection, teams can identify problems and fix them in the early stages through structured audits. As a result, there are many fewer defects, less downtime, and consistently smooth manufacturing operations.

In this article, we’ll explore the most common and effective manufacturing audits and how they work, helping your business ensure production quality control, compliance, and continuous improvement.

What Is a Manufacturing Process Audit?

A manufacturing process audit is a systematic examination of the production process that inspects and verifies that everything is done according to the proper standards and procedures.

In plain terms, it’s a thorough check-up of the manufacturing line that verifies operators follow work instructions, machines are set correctly, and materials and tools are used properly.

The main goal is to uncover any deviations, inefficiencies, or non-compliance in the manufacturing process to correct them before they lead to defective products or safety issues.

Keep in mind that there is no golden standard of auditing manufacturing processes. Instead, there are several main audit frameworks for businesses to choose from, varying in objectives, roles, schedules, and scope.

How Many Types of Audits Are There in the Manufacturing Industry?

There are four main types of manufacturing process audits: system audits, process audits, product audits, and compliance audits. Each type focuses on a different aspect of operations, from the overall management system to specific processes, finished products, or regulatory requirements.

What Is a Process Audit? Manufacturing Audit Scope Types and Examples

First off, we can categorize manufacturing process audits by scope, or in other words, by the primary focus of the audit:

1. System audits look at the big picture, meaning your entire management framework. They confirm that policies, structures, and procedures are strong enough to consistently deliver quality products.

2. Process audits dive into specific operations. For instance, auditors may observe how work is actually done on the shop floor: Are instructions followed? Is the machinery running as it should? Any bottlenecks or variations? The goal here is to verify both efficiency and compliance at the process level.

3. Product audits focus on inspecting finished output. A batch or single product is checked against all quality control and customer requirements, for example, pulling a vehicle off the line for a bumper-to-bumper inspection.

4. Compliance audits confirm that your operations meet all internal policies and external regulations, from OSHA safety standards to environmental requirements and beyond.

In practice, many audits combine these scopes or create their own hybrid approaches. The great thing is that manufacturing process audits can be tailored to your unique operations. You decide if you’re examining the whole system, a particular process, a product output, or a compliance area (or some combination) based on your objectives.

Manufacturing Process Audit Methodologies

There are numerous manufacturing process audits for companies to choose from, depending on their operations and goals. Each approach has its own primary focus and advantages, and most companies create a combination of several methods to create a tailored program for their operations.

As an example, businesses may run weekly Layered Process Audits (LPAs) to ensure standard procedures are consistently followed, while conducting quarterly compliance audits to ensure all regulations are being followed.

The one thing that all types of manufacturing audit frameworks have in common is that they work toward the same goal: proactively stopping issues in their tracks, validating process performances, and identifying opportunities to improve manufacturing operations.

What Is a Layered Process Audit?

Layered Process Audits (LPAs) are one of the most common methods of keeping manufacturing processes under continuous check. LPAs were initially created for the auto industry as a means of enforcing standardized work processes and detecting errors before they escalate into defective products.

Nowadays, they’ve become popular in virtually all production settings where process discipline is paramount, from manufacturing and electronics to health care and beyond.

The “layered” portion refers to who conducts the audits and with what frequency. Those closest to the work (shift supervisors and line workers) conduct the most frequent inspections, sometimes even daily, targeting low-level process details such as machine settings, tool calibration, and operator technique.

Mid-level managers audit less frequently, perhaps weekly, to examine the process as a whole and ensure front-line audits are resulting in improvements. And at the top layer, plant managers or executives audit monthly or quarterly to examine and adjust all the strategic, high-level production decisions.

The great thing about LPAs is that every team member, from line workers to executives, is involved in these audits one way or another, fostering a culture of inclusion and continuous improvement. Ideally, every single person in the organization should have the freedom to voice their concerns and suggest improvements.

LPAs’ greatest advantage is that they stop issues before they ever get to the customer. Rather than waiting to examine finished products, LPAs examine process inputs and variations, which research has shown result in about 75% of manufacturing defects.

Naturally, functional and effective LPA implementation requires serious initial planning and ongoing discipline from everyone involved. Roles have to be assigned, checklists for all layers have to be created, and each audit has to be followed up on.

But once established, LPAs foster a culture of accountability and continuous improvement. Everybody knows they have a voice and that each process could be audited at any moment, and that collective responsibility helps maintain high standards at all times.

Layered Process Audits Checklist Template

Launching a Layered Process Audit (LPA) program doesn’t have to be complicated, but it does require structure and follow-through. Here’s a simple breakdown on how to set it up effectively:

1. Define the purpose and scope: Clarify what your LPAs are meant to achieve. Are you targeting a specific production line, quality risk, or regulatory requirement? Decide which processes and standards each audit layer should verify, and ensure workers across all layers clearly understand these goals.

2. Build a layered audit team: Select auditors from different organizational levels: line leaders for daily operations checks, department managers for weekly oversight, and senior leaders for monthly or quarterly reviews. Ideally, the business could also assign a program coordinator to keep everything organized.

3. Create focused checklists: Each layer needs a short, targeted checklist, ideally 10–12 items, covering the most critical process steps or risk points. Keep the questions simple, preferably yes/no or pass/fail, to make spotting non-conformances quick and unambiguous.

4. Set a consistent schedule: Decide how often each audit should occur. The most common LPA rhythm includes daily front-line audits, weekly manager-level audits, and monthly or quarterly executive checks. Stick to a calendar and avoid skipped audits. Start small if needed, then scale frequency as the team adapts.

5. Train and communicate: Before launch, train auditors on how to perform LPAs and emphasize that the goal is improving processes, not blaming individual workers. Let all team members know why audits are happening. This transparency encourages cooperation and honesty.

6. Execute, document, and act: Perform audits on schedule, record all findings, and assign corrective actions right away for any deviations. Simple fixes (like a missing safety guard) should be addressed immediately, while recurring issues go to engineering or quality teams for root-cause analysis.

7. Review and improve: Regularly review audit data to spot trends and recurring failures, and adjust checklists or processes accordingly. Close the loop by confirming that lower-level findings are resolved, and celebrate achieved improvements to reinforce the value of these audits.

When done correctly, LPAs create a continuous feedback loop where process adherence is constantly monitored and improved. Companies that sustain regular LPAs often see a measurable drop in defects and a stronger, more accountable organization culture.

Industry leaders use Tervene to streamline audits, inspections, and corrective actions

Industry-Specific Audits

Each industry has its own unique requirements, and therefore, the same is true for how audits are performed. Although the underlying fundamentals of manufacturing process audits are the same everywhere (validate process, identify gaps, facilitate improvement), the particular frameworks or focuses may differ by industry.

Effectively, industry-specific audits start with the overall concept of a process manufacturing audit and then specialize in the industry’s particular requirements, risk points, and associated standards.

Businesses should always know the industry standards and best practices for auditing in their specific sector, as they usually derive from industry associations or regulatory authorities and are customized to cover the common failure modes within that industry.

To get a better understanding, let’s take a look at one of the most audit-intensive sectors, the automotive industry, and explore how its individual standards influence process audits.

Automotive Industry: IATF & ISO TS 16949 Audits

IATF is the global quality standard that governs automotive manufacturing audits. Specifically tailored for automotive manufacturing, it requires organizations to maintain a rigorous internal audit program covering their entire operation, from the quality management system to individual processes and final products.

Manufacturers must audit every production process across all shifts within a three‑year cycle, ensuring that tools like PFMEA (Process Failure Mode and Effects Analysis), control plans, and documented checks are regularly implemented and maintain effectiveness. In practice, this transforms the audit process from just verifying that operators follow instructions to confirming that all process risks are understood, monitored, and actively controlled.

ISO/TS 16949, while still referenced in automotive manufacturing, is the predecessor to IATF. It was officially replaced in 2016 but carried the same core intent: enforce a structured, comprehensive audit system that drives defect prevention and process consistency.

In addition, the CQI-8 Layered Process Audit (LPA) guideline, published by the Automotive Industry Action Group (AIAG), plays a central role in helping manufacturers apply IATF requirements on the shop floor. CQI-8 provides a structured framework for LPAs, ensuring that audits at all organizational levels consistently verify standard work, detect process risks early, and sustain process discipline.

Many automakers merge these mandatory IATF audits with additional auditing frameworks, for instance LPAs, to achieve near‑zero defect manufacturing performance.

Digital Manufacturing Process Audits

In the era of Industry 4.0, digital audits are transforming how manufacturers check their processes. The audits themselves, whether process, compliance, or LPA, haven’t changed much.

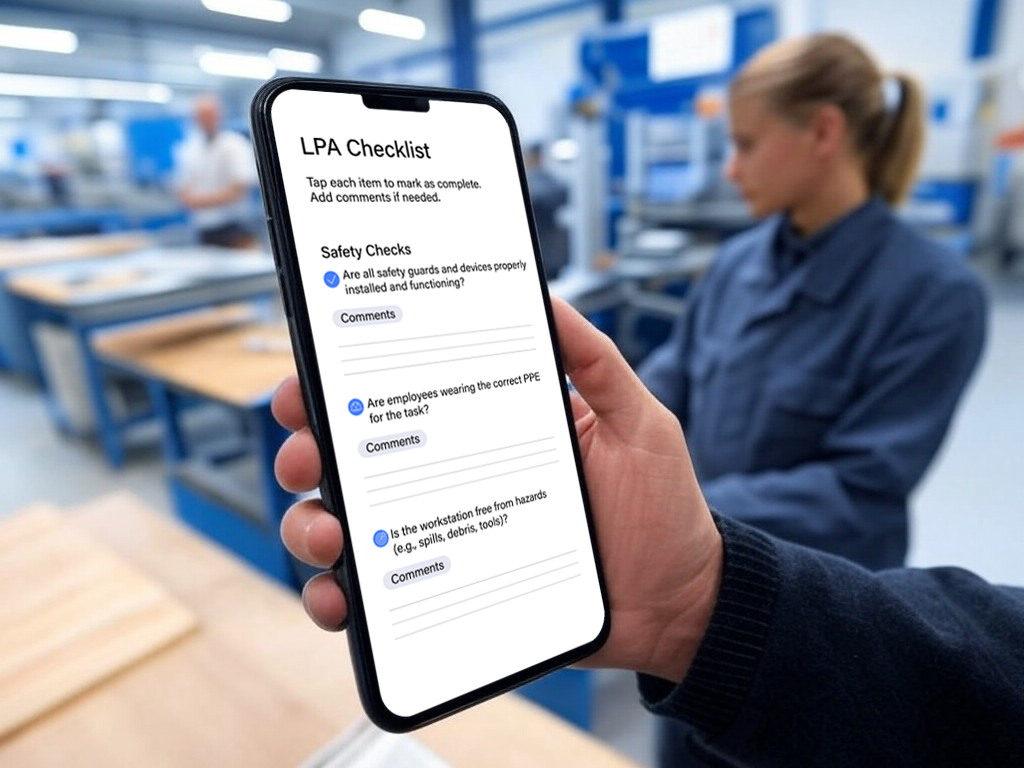

What has changed is how they’re conducted and managed. Instead of clipboards and Excel sheets, auditors now use digital tools like Tervene to create and operate their checklists, schedule audits, communicate, and log observations.

This technological change significantly simplified the entire manufacturing process audit. For instance, a shift supervisor can walk through the shop floor with a digital checklist, take a photo of a misaligned part, and immediately turn in the audit.

Management gets results right away, and if something is noted “Not OK,” the software can automatically generate a follow-up action or assign the right person for the task.

The major advantages of digital audits include:

- Real-time data and analytics: Immediate insight into results, automated dashboards, and trend tracking across shifts or site, no manual reporting required.

- Streamlined scheduling and responsibility: Automated reminders and audit assignments keep the cadence on track without constant manager follow-ups.

- Rich data capture: Photos, videos, and notes provide visual evidence and context for faster, more accurate problem-solving.

- Efficient corrective actions: Non-conformances can generate tasks on the spot, and progress is tracked automaticall, dramatically improving closure rates.

For large plants or multi-site operations, digital audits are a real game-changer. They enable remote visibility, eliminate paperwork, and create a truly data-driven approach to continuous improvement. In many cases, the investment quickly pays for itself in efficiency gains and prevents issues.

Here’s how Tervene helps manufacturing companies digitalize manufacturing process audits according to Rendy Samson, Continuous Improvement Coordinator at Manac:

It’s an all-in-one system that includes all the activities that support our daily management system: meetings, shift handover, improvement opportunities, audits, information center. For continuous improvement, we do problem-solving at its source. We are working with Lean principles, A3s, and the PDCA cycle.

Discover Tervene’s auditing tools

PCB Audit Checklist

When talking about manufacturing audits, we mostly refer to internal processes. But there is one more piece to the puzzle, and that is auditing the manufacturing suppliers.

A Process Control/Process‑Based (PCB) manufacturing audit is a methodical assessment of a supplier’s capacity to continually fulfill an organization’s production and quality control requirements. It audits their supply quality, processes, quality systems, compliance, and risk management to create a reliable and future-proof supply chain.

A robust PCB manufacturing audit must focus on five main points:

1. Quality System and Documentation: Ensures the supplier has an operational quality management system in place with defined procedures, their own internal audits, and a non‑conformance handling process. Documentation should be current, accessible, and actively used to drive process discipline, not just a binder on a shelf.

2. Equipment and Process Control: Evaluates how production processes are controlled and monitored. Are machines maintained and calibrated? Are key steps monitored with in‑process inspection or statistical process control (SPC)? Good control of equipment and processes minimizes variability and avoids defects before they occur.

3. Risk Management and Compliance: Verifies compliance with regulatory, safety, or environmental standards, and examines how the supplier recognizes and mitigates these risks. A solid partner will have concrete procedures in place for corrective actions and contingency planning to avert potential disruptions.

4. Materials and Traceability: Inspects that all materials are properly sourced, stored, and tracked. Complete traceability, from incoming raw material to finished product, reduces the danger of undetected quality problems and enhances a company’s potential for rapid response to any issues.

5. Reliability and Continuous Improvement: Looks for evidence that the supplier actively measures performance, addresses findings, and improves over time. A culture of continuous improvement is a strong indicator of long‑term reliability.

Performing PCB audits, ideally on‑site, assures businesses that their suppliers are qualified and able to sustain quality and consistency under real operating conditions. Periodic supplier audits ensure your supply chain remains functional at all times and prevent any expensive surprises down the line.

Importance of Auditing the Manufacturing Process

While it may feel like a ton of extra work, the importance of audits cannot be overlooked. They’re one of the most powerful tools for protecting quality, efficiency, and your bottom line in the long run. By systematically checking how each process is performed, audits deliver numerous benefits that ripple through the entire manufacturing operations.

1. Catch defects before they happen. Audits verify that every step is performed correctly, stopping process deviations before they create defective products. Preventing scrap and rework upstream saves both money and reputation.

2. Reduce waste and lower costs. Well‑controlled processes mean less scrap, fewer warranty claims, and less wasted labor. Audits often uncover inefficiencies like bottlenecks or redundant steps, leading to leaner, more cost‑effective operations.

3. Improve consistency and product quality. When processes are followed the same way every time, product quality stabilizes and variation drops. Over time, that consistency strengthens customer satisfaction and brand reliability.

4. Strengthen compliance and risk management. Regular audits ensure safety protocols and regulatory requirements are met. Spotting a skipped checklist internally is far better than facing an accident or a failed external audit.

5. Boost efficiency and throughput. Auditors often notice small opportunities to streamline, like reducing unnecessary movement or idle machine time. Closing these gaps keeps cycle times closer to the ideal and lifts overall productivity.

6. Drive continuous improvement and engagement. Audits create a built‑in feedback loop, encouraging employees to identify problems and contribute ideas. When workers see issues addressed, they feel heard and become active partners in improvement.

7. Reinforce training and accountability. Audits ensure standard work sticks, highlight where retraining is needed, and demonstrate that leadership is engaged on the shop floor. Visible participation from managers sends a clear message: process discipline matters.

In short, process audits act as your safety net, catching problems early on, surfacing proactive opportunities for improvement, and uniting teams around quality. Skipping them might feel easier in the short term, but in manufacturing, they keep potential costly issues at bay and maintain long-term operational excellence.

Internal Manufacturing Process Audit Checklist

Understanding how manufacturing process audits work in theory is half the battle. Implementing them into existing operations while ensuring they are systematic, collaborative, and lead directly to improvement is a whole other story.

Here’s a simplified yet practical step‑by‑step approach to running internal manufacturing process audits:

1. Define objectives and scope: Decide exactly what you’re auditing and why. Are you checking compliance with ISO 9001, internal procedures, or safety standards? Is it a specific line, department, or full system audit? A clear scope keeps the audit focused and efficient.

2. Set criteria and prepare: Determine what you’ll audit against, internal work instructions, control plans, or regulatory requirements, and review these documents before stepping onto the floor. Look at past audit findings or non‑conformances to know where potential risks might lie.

3. Schedule and assign auditors: Pick a time when the process is active, and assign trained auditors who are independent of the area being audited. A lead auditor plus an observer works well for larger operations; small teams may only need one.

4. Conduct the audit at the Gemba: Go to the real place, observe the process, and engage operators with open‑ended questions: “Can you show me how you verify this step?” Compare what’s happening to what should happen. Check calibration dates, quality logs, and records on the spot. Stay objective, note evidence carefully, and keep the tone constructive. Audits are for improvement, not policing.

5. Document findings: Record each finding with clear evidence: what was expected, what was observed, and whether it’s a non‑conformance or positive observation. Specific examples (product serials, photos, timestamps) make follow‑up easier and prevent disputes.

6. Hold a closing meeting: Brief the area supervisor on what you found, clarify any questions, and thank the team for their cooperation. This keeps the process transparent and ensures no surprises in the report.

7. Report, assign actions, and follow up: Compile a concise audit reporting system with all findings and assign corrective actions with clear owners and deadlines. Verify completion and effectiveness, sometimes through a quick re‑audit. Closing the loop is what turns an audit from a checklist exercise into real process improvement.

When internal audits are consistent and constructive, they become less about “passing or failing” and more about revealing the truth of the process. Teams learn to view audits as support, not punishment, and external audits become easier because issues are caught and corrected long before outsiders arrive.

Tervene helps you build a robust audit program that strengthens processes, reduces risks, and ensures compliance

Manufacturing process audits are one of the best ways to catch issues early, improve consistency, and drive continuous improvement, but running them manually can be a real headache. Tracking checklists, schedules, and follow‑ups across multiple layers often turns into an admin burden that slows teams down.

Tervene simplifies the entire process, enabling manufacturing leaders to plan, execute, and follow up on audits in real time, whether it’s standardized LPAs or customized internal checks.

Auditors can create digital checklists on a mobile device, attach photos, and instantly trigger corrective actions all in one single platform. Managers get dashboards, reminders, and automated tracking, so nothing slips through the cracks and every non‑conformance is followed through to closure. By digitizing your audits, you get faster feedback, stronger accountability, and the visibility to continuously improve your operations.

Tervene makes audits effortless

- Perform your audits on mobile or tablet

- Build custom checklists

- Schedule periodic audits

- Report and monitor audit compliance throughout your team

FAQ: Manufacturing Process Audits

The 5 C’s of audit are Criteria, Condition, Cause, Consequence, and Corrective Action. They provide a structured way to document findings: compare the process against the standard (criteria), identify the current state (condition), determine why the gap exists (cause), explain its impact (consequence), and define how it will be corrected (corrective action).

The five key stages are: 1) Planning, 2) Preparation, 3) Fieldwork/Execution, 4) Reporting, and 5) Follow‑up. This sequence ensures the audit is systematic, from defining objectives to verifying that corrective actions are completed.

An LPA (Layered Process Audit) is a structured audit method where multiple organizational levels (frontline supervisors, managers, and executives) perform regular checks on the same process. LPAs focus on verifying that standard work is followed and catching process deviations before they create defects.

A manufacturing process audit involves planning the scope, preparing a checklist or criteria, observing the process on the shop floor, documenting findings, and following up on corrective actions. Auditors compare what is happening in real time against documented procedures and standards to ensure compliance and identify improvement opportunities.

They help identify process deviations early, prevent defects, improve product consistency, and ensure compliance with safety and quality standards. Regular audits also support continuous improvement and reduce operational risk.

A process audit evaluates how work is performed, checking if operators follow procedures, machines are calibrated, and controls are effective. A product audit inspects the final output to verify it meets quality and customer requirements.

Frequency depends on risk level and operational needs. Critical processes may be audited daily or weekly, while broader system or compliance audits are often conducted quarterly or annually. Layered audits combine multiple cadences.

Auditors use checklists, control plans, and audit forms to verify compliance. Many manufacturers now use digital audit software for real‑time data capture, scheduling, and tracking corrective actions.

A strong checklist covers process steps, equipment conditions, operator practices, documentation, and safety or regulatory requirements. It should focus on critical factors that affect product quality and process reliability.