12 Steps to Implement Layered Process Audits in Manufacturing

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | July 15, 2025 |

| Read time: | 7 min |

- Boosts Quality & Compliance: LPAs reduce defects, ensure regulatory compliance, and support operational excellence in manufacturing and healthcare.

- Structured & Scalable: Audits use standardized checklists and defined frequencies across all organizational layers.

- Drives Accountability: LPAs create visibility into frontline operations and promote a culture of ownership and continuous improvement.

This guide provides a straightforward and insightful resource to understand and implement a Layered Process Audit (LPA). Discover the 12 steps for integrating LPAs into operational frameworks.

What is a Layered Process Audit?

Layered Process Audits (LPAs) are structured evaluations spanning multiple organizational levels to ensure adherence to established processes and enhance performance within a quality management system.

Frontline employees, middle management, and upper management all participate in LPAs. Auditors utilize specific checklists aligned with their authority level to examine diverse workplace areas, standards, and criteria to guarantee compliance.

What are the three core layers of process audits?

LPA is a system built on 3 distinct layers, each of which exists for a particular reason and plays its unique role. You’ve got frontline staff, middle management, and top leadership — all looking at the exact same set of processes, but from very different angles. That’s what makes the audit actually work.

First layer: the floor-level view

This is where frequent, day-to-day checks occur, conducted by team leaders, shift supervisors, and other operators who are closest to the shop floor action. They’re always the first to notice if something is off, be it a missing step or a safety shortcut, and therefore are responsible for catching potential issues early on before they grow into bigger, often more expensive problems.

Second layer: the manager lens

Managers step in less often, usually weekly, but their role is just as critical. They don’t simply check if rules are followed — they look at whether the entire process is holding up. Is that recurring issue identified in the first layer actually fixed, or just band-aided? Are frontline audits being done properly? They connect the dots and start spotting patterns that might not be obvious to those with boots on the ground.

Third layer: leadership involvement

This one’s often overlooked, but it could potentially be the most important. When plant managers or senior leaders step into an audit, it sends a message — this stuff matters. Rather than micromanaging, they focus on the bigger picture: long-term trends, systemic issues, and whether the entire process is supporting company goals.

These three layers reinforce one another. It’s not about hierarchy, it’s about perspective. When all three layers are working cohesively, the LPA becomes a functioning loop of accountability, insight, and constant improvement.

Benefits of Layered Process Audits

Implementing a layered process audit (LPA) program can bring numerous benefits to an organization. Some of the key advantages of LPAs include:

- Enhanced Quality Management: LPAs help ensure that manufacturing processes are effective and efficient, reducing the risk of defects and improving overall product quality.

- Increased Efficiency: By identifying and addressing potential issues early on, LPAs can help streamline processes, reduce waste, and improve productivity.

- Improved Compliance: LPAs help companies meet industry regulations and uphold quality standards, reducing the risk of non-compliance and costly rework. Quality and compliance go hand-in-hand when process control is maintained across all layers.

- Reduced Defects: LPAs can help identify and address potential defects early on, reducing the risk of costly rework and improving overall product quality.

- Improved Customer Satisfaction: By ensuring that products meet quality and safety standards, LPAs can help improve customer satisfaction and loyalty, and reduce the number of customer complaints in the long run.

- Cost Savings: LPAs can help reduce costs associated with rework, scrap, and warranty claims, improving overall profitability.

- Improved Employee Engagement: LPAs can help engage employees in the quality management process, improving morale and motivation.

- Continuous Improvement : LPAs provide a framework for continuous improvement, helping organizations to identify and address areas for improvement.

- Improved Workplace Safety: LPAs help catch hazards early, reinforce safe practices, and build accountability. Paired with safety management tools, they strengthen your prevention efforts and overall safety culture.

Industry leaders leverage Tervene to perform their audits & inspections

Steps to implement a Layered Process Audit

1. Learn About LPA Best Practices

In implementing a Layered Process Audit (LPA), it’s essential to grasp the best practices that underpin its effectiveness. Here are three of the most critical LPA best practices:

- Inclusive Engagement: The involvement of employees at all levels, from frontline operators to upper management, builds a collaborative and thorough auditing process.

- Focus on Prevention: LPAs emphasize identifying and preventing issues before they escalate to reduce the likelihood of defects or errors in the final product.

- Standardization: Layered Process Audits often involve standardized checklists and procedures to ensure consistency in auditing processes across different levels and areas.

Conducting layered process audits effectively requires adherence to best practices, such as educating leadership, setting clear objectives, and forming an audit team. Implementing a Lean Management System can support these efforts by reinforcing daily discipline, standardization, and a culture of accountability — all essential for a successful LPA rollout.

2. Assemble a Team

To kickstart a Layered Process Audit program, identify key stakeholders and ensure representation from each layer involved in the LPA process. This team should include at least one representative from frontline employees, middle management, and upper management. Assign clear roles and responsibilities, such as program lead, training specialist, documentation or data manager, communication liaison, and more.

Emphasize the importance of cross-functional collaboration to promote a culture of full organizational participation. A well-structured and collaborative team lays the foundation for the successful execution of the LPA program and gathers insights from all organizational levels to create a culture of continuous improvement.

3. Identify Processes (LPA Scope)

Defining the scope of a Layered Process Audit involves methodically identifying critical processes and requires consideration of essential business functions. By pinpointing these auditable processes, including various layers of the manufacturing and production process, the LPA scope accommodates the specific needs and priorities of the organization.

For instance, auditing the production line, supplier selection, procurement, quality control, and inventory management ensures adherence to quality standards while maintaining the supply chain’s integrity. Regular audits of equipment maintenance procedures are crucial to prevent breakdowns, enhance reliability, and sustain consistent production.

4. Build Custom LPA Checklists, Forms & Templates

A robust Layered Process Audit involves tailored checklists for each auditable area. Preparing thoughtful audit questions is essential. This preparation includes listing various types of questions custom-made to specific audit objectives. Incorporate open-ended questions to encourage detailed responses. By crafting practical audit questions, your LPA process gains depth and precision in uncovering vital process insights.

Utilizing layered process audit checklist templates can standardize and streamline the checklist-building process, ensuring consistency and thoroughness in audits.

Discover Tervene’s LPA tools

5. Schedule Audits

The frequency of Layered Process Audits depends on the organizational level overseeing the audit. Proximity to the audited area influences audit frequency. For instance, line supervisors may conduct daily audits, while plant managers may opt for a monthly cadence.

Moreover, LPA schedules play a pivotal role in implementing Leader Standard Work. Establishing a structured LPA schedule for regular assessments is vital. Auditors can select from daily, weekly, monthly, or custom recurrence options to consistently uphold diligence and meet deadlines. This strategic integration ensures a systematic and efficient approach to audit planning aligned with the principles of Leader Standard Work.

6. Determine Project Schedule

This step highlights the foundational role of a well-structured schedule in the LPA initiative’s success. Leveraging visual tools, such as a Gantt chart, aids in translating this schedule into a dynamic timeline. The Gantt chart provides a clear, intuitive representation of each audit step to promote effective communication and coordination.

Beyond a chronological display, it strategically enhances transparency, identifies dependencies, and ensures seamless alignment of every facet of the Layered Process Audit with the predetermined schedule.

7. Assign Multiple Layers of Auditors

In assigning auditors across different management layers, articulate a transparent process to build a competent audit team. This selection involves a strategic approach where team leaders may audit frontline operators, managers audit team leaders, and so forth. Following this structured process, each management layer becomes actively involved in the audit cycle.

8. Provide LPA Team Training

From upper management to floor staff, delineate the training requirements for auditors and team members. It’s also important to recognize the diverse skill set needed at each level (floor staff might require more training). This exercise must encompass valuable resources and varied training methods tailored for LPA education.

9. Establish Escalation and Problem Resolution Procedures

Identify specific support teams and define their roles, then indicate accessible communication channels for reporting and seeking assistance. Clearly outline an issue escalation hierarchy based on severity and complexity and develop a structured communication cascade that facilitates bottom-up and top-down information flow. This proactive approach ensures a resilient and responsive operational framework capable of swiftly addressing challenges.

10. Conduct the Layered Process Audit

Executing a Layered Process Audit involves a systematic approach supported by thorough process audit checklist reviews and keen observations. The audit process is structured to ensure comprehensive coverage and emphasize the importance of meticulous examination. This step-by-step execution calls for checklist scrutiny and on-site observations. It is pivotal for uncovering insights and fostering continuous improvement.

11. Record, Analyze the Findings, and Roll Out Corrective Action Plans

Post-audit, the meticulous process begins with documenting findings to record positive observations and areas requiring improvement. These reported results are then systematically analyzed to discern trends, recurring issues, and potential areas for process enhancement.

Identifying discrepancies lays the foundation for strategic corrective actions and proactive improvements. This step emphasizes the importance of continuous monitoring and auditing improvement while integrating a dynamic feedback loop.

12. Reviewing and Continually Improving the LPA Program

Layered Process Audit programs must go through an ongoing evolution. This progression involves a reflective examination of the LPA implementation process and incorporating valuable feedback from auditors and stakeholders. The strategic management of corrective and preventive actions when discrepancies are identified is also crucial.

A robust feedback loop is established to sustain the LPA program when audit results and improvement actions are shared with relevant stakeholders, enhancing overall quality management processes. This commitment to transparency is critical in building awareness and fostering a culture of accountability.

The CQI-8 Layered Process Audit Guideline

For organizations seeking to implement LPAs by the book, the CQI-8 Layered Process Audit Guideline is a valuable resource. Initially developed by the Automotive Industry Action Group (AIAG), this guideline provides in-depth insights, standardized practices, and a reference point for enhancing the effectiveness of process performance across a variety of industries.

At its core, CQI-8 is about making LPAs repeatable, reliable, and actually useful. It outlines everything from how often audits should happen and how roles and responsibilities are divided across layers of your team, to how to write meaningful checklist questions that surface real issues.

Overcoming Common Challenges in LPA Implementation

Implementing a layered process audit program can be challenging, but there are several strategies that can help overcome common obstacles. Some of the key challenges and solutions include:

- Lack of Buy-In: Educate leadership and employees on the benefits of LPAs and involve them in the implementation process to ensure buy-in and support.

- Limited Resources: Prioritize processes and focus on high-risk areas to ensure that LPAs are effective and efficient.

- Complexity: Break down complex processes into smaller, more manageable sections, and use checklists and templates to simplify the audit process.

- Resistance to Change: Communicate the benefits of LPAs and involve employees in the implementation process to reduce resistance to change.

- Limited Training: Provide regular training and support to ensure that employees have the skills and knowledge needed to conduct effective LPAs.

Leveraging Technology for Efficiency in LPAs

Technology can play a key role in improving the efficiency and effectiveness of layered process audits. Some of the ways that technology can be leveraged include:

- Digital Checklists: Use digital checklists to simplify the audit process and reduce errors. For example, digitizing your 5S audit checklist is an effective way to standardize frontline checks and reinforce lean practices during daily LPAs.

- Audit Software: Use audit software to streamline the audit process, track findings, and analyze data.

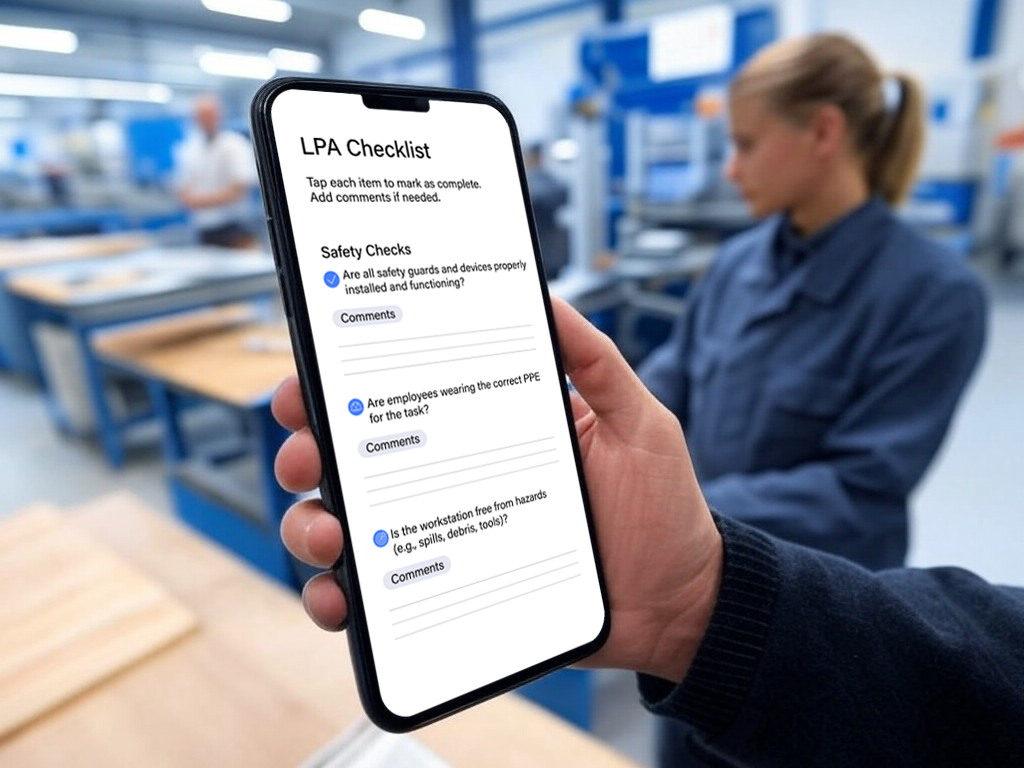

- Mobile Devices: Use mobile devices to conduct audits and collect data in real-time. A digital audit and inspection app can help streamline the process by standardizing how observations are captured, logged, and shared across teams.

- Data Analytics: Use data analytics to identify trends and patterns in audit data, and to inform continuous improvement initiatives.

- Cloud-Based Solutions: Use cloud-based solutions to store and share audit data, and to facilitate collaboration and communication.

By leveraging technology, organizations can improve the efficiency and effectiveness of their LPA programs, and achieve greater benefits from their quality management initiatives.

Layered Process Audit Software

Tap into the full potential of Layered Process Audits (LPAs) through successful implementation with Tervene. Seamlessly integrate your existing LPA processes in the application and benefit from a user-friendly interface. Experience real-time monitoring and reporting capabilities that provide valuable insights for swift decision-making.

Tervene’s platform helps streamline layered process audits by providing instant updates, scheduling, and streamlined communication, enhancing the efficiency and effectiveness of the auditing process.

Access comprehensive training and support resources to empower your team and optimize your audit management. For an in-depth exploration and advanced tools, see Tervene in action.

Tervene: Leader of digital LPA tools

Tervene is a leading provider of digital Layered Process Audits. Our tools empower organizations to enhance quality, efficiency, and compliance. With a proven track record across manufacturing and healthcare industries, Tervene helps hundreds of clients reach new heights of operational performance.

Tervene makes LPAs effortless

- Perform your LPAs on mobile or tablet

- Build custom LPA checklists

- Schedule periodic LPAs

- Report and monitor LPA compliance throughout your team

FAQ: Layered Process Audit (LPA)

A Layered Process Audit is a structured auditing approach that involves multiple levels of an organization—frontline staff, supervisors, and senior leaders. Each level uses standardized checklists to verify adherence to operational processes, safety protocols, and quality standards.

All organizational levels, including operators, team leaders, department managers, and executives, should take part. Their involvement ensures alignment and accountability throughout the organization.

In manufacturing, LPAs help detect quality issues early, reduce scrap, and maintain process reliability. In healthcare, they ensure compliance with safety procedures and clinical standards, minimizing patient risk and regulatory non-conformance.

-

Reduced defects and rework

-

Increased compliance with regulations (ISO, FDA, etc.)

-

Higher process efficiency and consistency

-

Better employee engagement and ownership

-

Improved customer satisfaction and cost control

-

Stronger culture of continuous improvement

Frequency depends on organizational level. For example:

-

Frontline leaders: daily or shift-based audits

-

Department heads: weekly audits

-

Plant managers or directors: monthly reviews

Focus on high-risk and critical operations such as:

-

Production lines and workstations

-

Equipment maintenance

-

Supplier quality

-

Clinical procedures (healthcare)

-

Safety and compliance protocols

-

Custom or templated audit checklists

-

A clear audit schedule

-

Escalation and resolution workflows

-

Audit tracking software like Tervene

-

Data analysis dashboards

Digital platforms like Tervene enable real-time data capture, simplify scheduling, and support mobile audits. They also enhance traceability, ensure timely corrective actions, and provide insights via analytics.

Provide role-based training that covers:

-

Audit objectives and procedures

-

Checklist usage

-

Observation techniques

-

Escalation protocols

Training should be continuous and adapted to each level’s responsibilities.

Post-audit steps must include:

-

Documenting findings

-

Analyzing recurring issues

-

Assigning corrective actions with deadlines

-

Following up on resolutions

-

Sharing outcomes with all stakeholders

-

Lack of management buy-in

-

Resistance to change

-

Inadequate training

-

Resource constraints

-

Poor follow-through on corrective actions

Overcome them by securing leadership support, prioritizing training, and using digital tools to track accountability.

Yes. LPAs are particularly valuable in meeting requirements set by ISO 9001, IATF 16949, FDA regulations, and internal QMS standards. Regular audits prove due diligence and process control.

Tervene simplifies LPA implementation through:

-

Mobile and web audit platforms

-

Real-time reporting

-

Digital checklists

-

Automated scheduling

-

Escalation management

-

Continuous improvement tracking

It centralizes your audit data and accelerates problem resolution across departments.