Leader Standard Work Template, Checklist and Example

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | August 23, 2024 |

| Read time: | 6 mins |

- Customizing your calendars with our free downloadable templates.

- Downloading our 4-week implementation eBook for a step-by-step guide.

- Exploring Tervene, our LSW software.

Leader Standard Work (LSW) unlocks operational excellence by defining and standardizing a manager’s daily, weekly, and monthly tasks. In turn, it eliminates process variation and establishes a framework for proactive leadership.

In this article, we’ll delve into the details of LSW, highlight the benefits, provide sample checklists, and suggest practical template ideas.

From manufacturing to healthcare facilities, we’ve guided hundreds of organizations like yours on their journey to LSW mastery. Our approach will transform your managers into strategic leaders who unlock your team’s full potential and ensure that every action aligns with your overarching company goals.

What is Leader Standard Work?

Leader Standard Work is an established set of routines, processes, and tasks that guide managers towards consistent and efficient performance. Its core purpose is to incorporate structured actions and tools into leadership practices to problem-solve faster, collaborate smarter, and keep everyone on the same page.

Implementing Your LSW Program

These steps will help you standardize your supervisors’ and managers’ routines, ensuring that all essential tasks and activities are performed consistently and according to a schedule.

- Identify Key Tasks and Activities:

Assign responsibilities to each tier of leadership, from shop floor to boardroom. Review job descriptions, standard operating procedures, and other relevant documentation to distribute the right tasks to the right people.

- Group Tasks and Management Activities:

Categorize tasks and activities into daily, weekly, and monthly frequencies. This method establishes a consistent workflow, giving supervisors and managers a sense of control and organization.

- Create a Calendar:

Place your routine tasks on a shared calendar so all stakeholders know exactly when, where, and how each task will be unfolding. Best practice: use a digital calendar tool for clarity and accessibility.

- Monitor and Adjust:

Continuously monitor the routine’s effectiveness and adjust as needed. You may notice that some tasks need to be performed more or less frequently or may be better off assigned to another leader.

- Train and Coach:

Train new supervisors and managers on all relevant standardized routines to ensure they understand their responsibilities and the timing of critical activities.

LSW Templates and Checklists

Start mapping out your LSW routine with templates and checklists

Task Ideas for Your LSW Calendars

Need inspiration? Start building your calendar with whichever routine tasks apply to your leadership teams.

- Gemba walk

- Shop floor tour

- Waste tour

- Kickoff flour tour

- Safety inspection

- Monthly EHS audit

- Quality assurance inspection

- 5S process checklist

- Behavior-based safety audit

- Fire hazard and emergency audit

- Layered process audit (LPA)

- Setup procedure audit

- LOTO process audit

- Preventive maintenance inspection

- Respond to emails

- Check progress of ongoing projects and adjust schedules

- Review daily attendance

- Daily huddle

- Production meeting

- Daily management meeting (DMM)

- Weekly plant review

- Pre-shift meeting with production team

- One-on-one meeting

- Shift handover

- Quality assurance meeting

- QRQC meeting

- Board performance meeting

- Preventive maintenance meeting

- Continuous improvement committee meeting

- Health and safety committee meeting

- Brainstorming session

- Coaching and training session

- Project management

- Performance evaluation/employee feedback

Relevant Tervene Solutions

Inspiration: Daily Management Activities

Keep tabs on your company’s everyday productivity with these routine task ideas:

- Review daily production reports and adjust plans as necessary.

- Conduct a daily meeting with supervisors to discuss any issues or concerns.

- Perform safety inspections and ensure adherence to safety protocols.

- Monitor quality control processes and address any problems that arise.

Inspiration: Weekly Management Activities

These weekly LSW responsibilities will keep all levels of management in sync and enable continuous improvement:

- Hold regular department head meetings to discuss progress, challenges, and areas of improvement.

- Analyze production data to identify trends and opportunities.

- Conduct training sessions to develop employee skills and knowledge.

- Meet with suppliers to discuss pricing and delivery terms.

Inspiration: Monthly Management Activities

Monthly tasks tend to focus more on big-picture objectives and long-term progress monitoring.

- Set a monthly meeting with senior management to review the organization’s performance.

- Reassess and update employee training programs.

- Analyze customer feedback and implement improvements to products and services.

Sample Schedule: A Day in the Life of a Leader

This sample schedule outlines the core activities that make for a successful leader. Adapt the specific allocation to align perfectly with your unique role and priorities.

| Time | Activity / Task |

|---|---|

| 7:00 am | Kickoff meeting with the frontline team (5 minutes) |

| 7:30 am | Walk through departments to observe operations (15 minutes) |

| 8:00 am | Hold a daily management meeting to review reports and adjust plans as necessary (30 minutes) |

| 9:00 am | Respond to emails and voicemails from staff, customers, and suppliers (1 hour) |

| 10:00 am | Conduct a safety inspection (30 minutes) |

| 11:00 am | Lunch break (1 hour) |

| 12:00 pm | Conduct performance evaluations and provide feedback to staff (45 minutes) |

| 1:00 pm | Check the progress of ongoing projects and adjust schedules as necessary (30 minutes) |

| 2:00 pm | Meet with quality, health, and safety department heads to discuss progress, challenges, and areas of improvement (45 minutes) |

| 3:00 pm | Analyze operational data to identify trends and opportunities for improvement (30 minutes) |

| 4:00 pm | Conduct an end-of-shift proactive Gemba Walk to identify issues and noncompliance (15 minutes) |

| 4:30 pm | Hold a shift handover meeting with the incoming team (10 minutes) |

Weekly Leader Standard Work Example

This sample plan outlines a high-performing leader’s core weekly activities. Tailor this template to suit your company and goals.

Monday | Data-Driven Planning

- Review last week’s production data.

- Conduct a floor walk using a checklist to evaluate the production process.

- Meet with team leads to discuss issues or concerns.

- Develop a plan to meet production targets for the week.

Tuesday | Collaboration & Optimization

- Hold a weekly management meeting with department heads.

- Check equipment and machinery for defects.

- Respond to emails and voicemails from staff, customers, and suppliers.

- Meet with team members to discuss opportunities for improvement.

Wednesday | Continuous Improvement

- Conduct a standard Gemba walk to identify potential waste and improvement opportunities.

- Review and update ongoing continuous improvement initiatives.

- Develop a plan to address issues identified during the week.

Thursday | Quality & Control

- Perform a 5S audit using a checklist.

- Review and address quality control results.

- Manage inventory levels and coordinate with procurement.

- Walk the site to ensure proper shutdown procedures are followed.

Friday | Strategic Planning & Support

- Conduct a health and safety inspection.

- Review progress toward production targets.

- Identify areas needing additional support or resources.

- Update production targets for the upcoming week.

10 Steps to Implement Leader Standard Work in 4 Weeks

How Calendars Help Managers & Supervisors

A standardized management calendar clearly outlines expected tasks and activities while establishing a culture of accountability and responsibility. This simple but critical approach minimizes the risk of overlooking crucial tasks by clearly laying them out and making them accessible to the entire team.

Tasks can be assigned to specific owners, and collaborators can be added for a layer of support and accountability.

The calendar also allows you to set the time and frequency of each task to guarantee they are completed on time and consistently.

Many management calendars even offer color coding functionalities, which can improve visual management by allowing you to identify tasks and their status at a glance quickly.

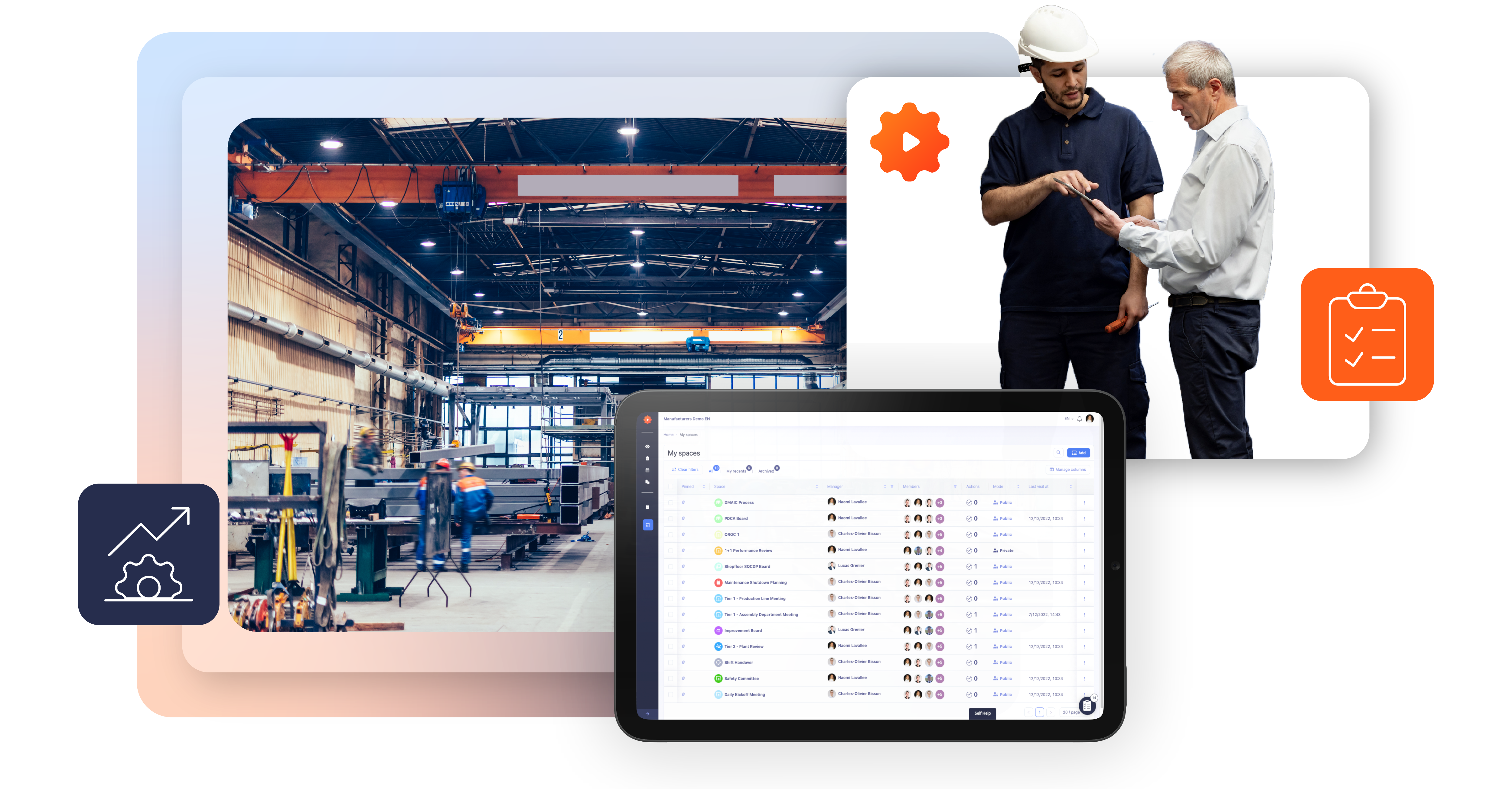

The Must-Have Software for Ops Leaders

Tervene has all the tools you need to implement, maintain, and optimize a Leader Standard Work program. It provides simple and effective frameworks for Gemba walks, tiered meetings, audits, inspections, and more, making it easier than ever to manage and track routine responsibilities.

Take the first step towards a more efficient and organized Leader Standard Work program.

FAQ About LSW

LSW is a system that defines a manager’s essential daily, weekly, and monthly tasks. It ensures consistent routines and prioritizes activities that directly impact your goals.

- Increased Efficiency: LSW eliminates wasted time and ensures critical tasks are completed.

- Improved Communication: It promotes clear communication between leaders and teams.

- Standardized Practices: LSW establishes consistent routines across all management levels.

We recommend following these steps:

- Utilize our free Leader Standard Work Templates & Checklists to customize your daily, weekly, and monthly schedules.

- Download our free 10 Steps to Implement Leader Standard Work in 4 Weeks eBook for a detailed roadmap.

- Explore Tervene, our all-in-one LSW management software, to streamline task management and gain valuable insights.

The free downloadable templates offer customizable calendar formats for daily, weekly, and monthly schedules. They also come with pre-populated task ideas to jumpstart your LSW routine, saving time and effort.

Yes! Tervene is our all-in-one software designed to simplify LSW program management. It allows you to schedule tasks directly into leader calendars, track progress, and gain valuable insights.

LSW applies to managers at all levels, from supervisors to executives. It helps ensure everyone is working towards the same goals and that critical tasks aren’t overlooked.

More Articles From Our Experts

Here’s the Ultimate Leader LSW Handbook. Drive Lean leadership efficiency and ensure operational excellence at all management tiers.

From promoting accountability to fast-tracking onboarding and increasing visibility, discover the 9 benefits of Leadership routines.

Spot improvement opportunities, anticipate issues, and drive operational excellence with these 6 Gemba Walk App Essential Features.