Operator Rounds: A 2026 Guide for Smarter Oversight

| Audience: | Manufacturing and Healthcare Executives, Lean Management and Continuous Improvement Professionals, Operational Leaders and Safety Officers |

| Last updated: | September 10, 2025 |

| Read time: | 12 min |

- Identify the early warning signs of inefficient, outdated, or unclear rounds.

- Learn how to modernize inspections with tools that boost safety, quality, and accountability.

- Follow a practical rollout plan to engage teams, reduce downtime, and build a culture of continuous improvement.

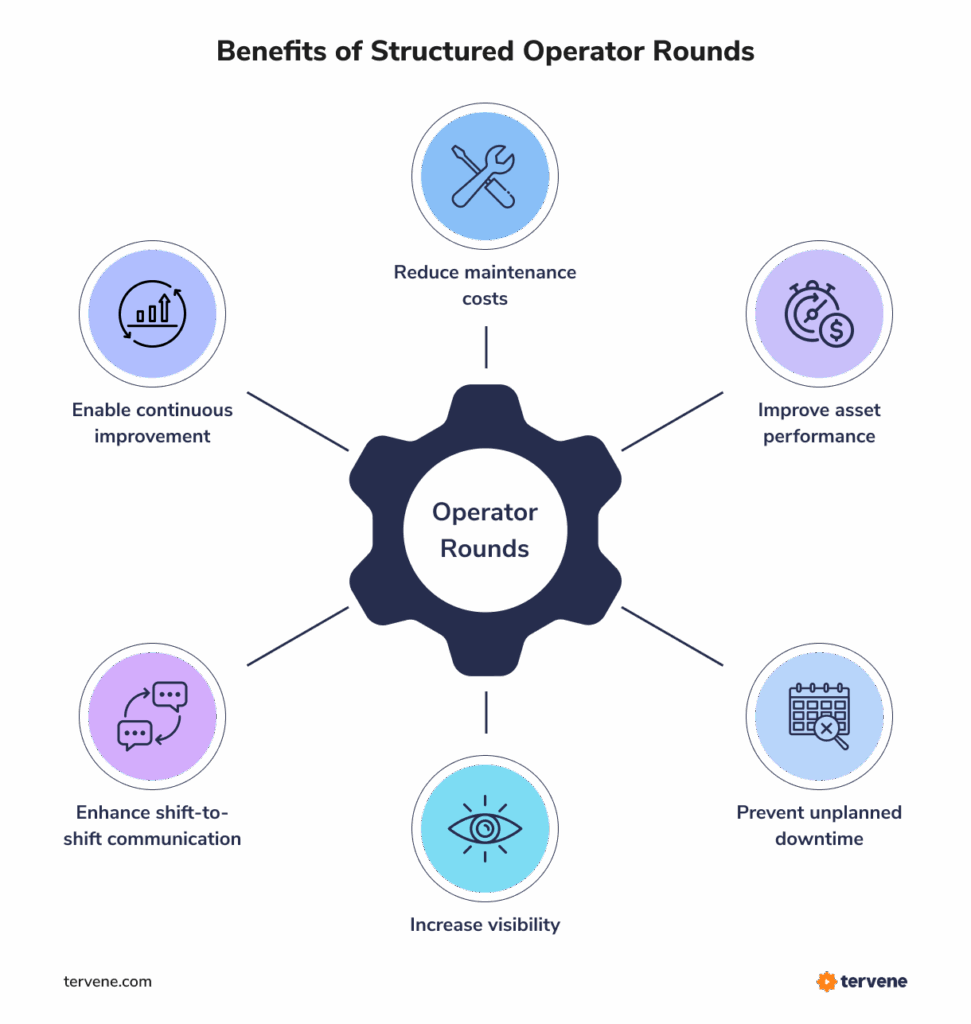

Operator rounds are routine checks that keep your equipment running and your workplace safe. Workers (operators) walk the floor, inspect machines, record data, and catch issues early. These rounds are simple, but when done right, they can prevent downtime, boost efficiency, and cut maintenance costs.

That’s why, in 2025, streamlining operator rounds isn’t optional. Labor shortages, rising maintenance costs, and tighter production schedules mean you’ve got to work smarter, not harder.

This guide is for plant managers, team leads, and anyone looking to improve frontline operations. You’ll learn how to spot issues, pick the right tools, roll out changes, and build a process that works better every day.

We’ll start with the essence and importance.

What are plant operator rounds?

At their core, operator rounds are about keeping your equipment running smoothly and your facility safe. They’re routine walk-throughs where operators check machinery, note readings, and spot problems before they become big issues.

The main goal? Catch early signs of trouble and keep things working efficiently. You’re looking, listening, feeling, and sometimes even smelling for anything out of the ordinary.

Here’s what these rounds usually include:

- Checking gauges, meters, and control panels

- Logging key data like temperatures, pressures, and fluid levels

- Inspecting equipment for leaks, noises, or vibrations

- Reporting or fixing minor issues on the spot

- Making sure safety protocols are followed

But rounds aren’t always smooth. The good news? Most of them are fixable with better tools and clearer processes. We’ll show you all the details in a moment.

Now that you’ve got a clear answer to the question, ‘What is the role of an operator?’, let’s take a closer look at how to improve their processes.

How do you spot inefficiencies in your current process?

Before you can streamline anything, you’ve got to spot what’s not working.

Operator rounds might look fine on the surface, but hidden inefficiencies can build up over time. The key is knowing what to look for, what data to track, and how to get honest input from the people doing the work every day.

So, how do you know when your current process isn’t working?

Signs your operator rounds need a revamp

You might not realize your rounds are off-track until issues pile up. Here are some red flags:

- Inconsistent reporting: Operators log different information for the same checks. That’s a sign the process isn’t clear, consistent, or leaves room for human error.

- Missed problems: Small issues turn into big ones because nobody caught them early.

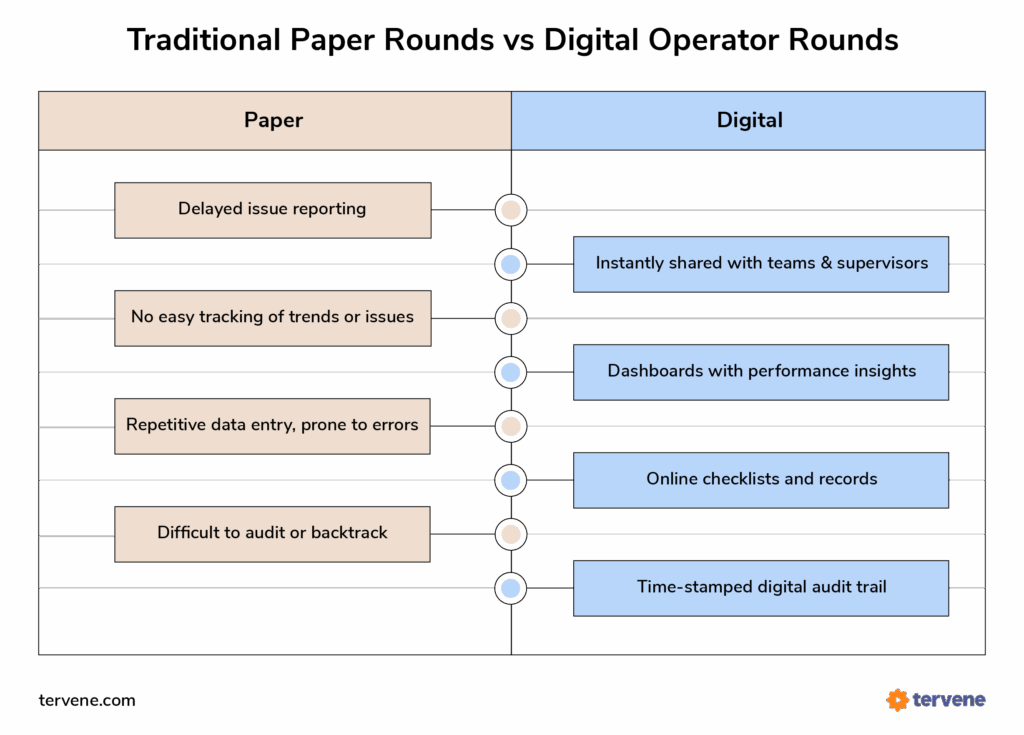

- Too much paperwork: If rounds feel like a paperwork exercise, not a value-add, it’s time to modernize.

- Slow response to issues: If it takes too long for reported problems to reach the right people, your communication flow is broken.

- Low morale or complaints: If workers feel like the rounds are pointless or a waste of time, they probably are.

If you’ve noticed even one of these, that’s your cue to take a closer look. And don’t worry, there’s always a fix. The next step is knowing what to measure.

Data you should be tracking with digital operator rounds

Start by tracking a few simple things like completion rate and time on task (we’ll cover a few more metrics a bit later). You don’t need a fancy system to start tracking. Even a basic spreadsheet can give you insight, but digital tools like Tervene can make this much easier over time. You can:

- Monitor live KPIs

- Track audit and routine plant inspection results

- Spot trends and take action fast.

It’s your go-to tool for structured rounds and smarter decisions. It helps managers stay proactive and in control every step of the way.

So, data tells one part of the story. But your operators see the process up close every day.

Relevant Tervene tools

How to gather honest feedback from operators

This part’s key. Your operators are on the front lines. They know where the process gets stuck. But you’ve got to make it safe and easy for them to share.

Here’s how to do it:

- Ask simple questions: Try “What’s slowing you down during rounds?” or “What do you wish you could change?”

- Use quick check-ins: Don’t wait for formal meetings. Casual chats during shift changes can reveal a lot.

- Anonymous surveys: Sometimes people are more honest when their name’s not attached.

- Involve them in solutions: Don’t just collect feedback—act on it. If they see their ideas making a difference, they’ll keep talking.

Make it clear you’re not looking to blame anyone. You’re just trying to make the job easier, safer, and more effective.

Once you know where the problems are, it’s time to explore tools that can help solve them.

What tools and technologies can help?

If you want to streamline operator rounds, tech is your best friend. The right tools can cut down on wasted time, improve accuracy, and help you catch problems before they snowball.

Let’s break down the main tools that can make a big impact:

| Tools | Description |

| Mobile apps and digital checklists | Paper logs are easy to lose and hard to share. Mobile apps solve that. Workers can complete operator inspection checklists, shift log issues, and snap photos—all from a smartphone or tablet.Everything’s saved instantly and shared with the right people. |

| IoT sensors and real-time data | IoT (Internet of Things) sensors continuously track machine health, like temperature, pressure, vibration, and more. Instead of waiting for a round to spot a problem, you get alerts the moment something goes off track.It’s like having extra eyes on every machine, 24/7. |

| AI and predictive maintenance | AI tools analyze data from your rounds and sensors to predict when a machine might fail. That means fewer surprises and more planned fixes.You stop reacting and start staying ahead. |

| Integration with CMMS and EAM systems | When your rounds connect directly to your CMMS (Computerized Maintenance Management System) or EAM (Enterprise Asset Management), everyone’s on the same page.Issues logged in rounds can instantly trigger work orders or routine plant inspections. |

Consider, for example, Tervene. It helps you digitize daily routines, lead smarter meetings, and solve issues faster. You’ll track KPIs in real time, standardize audits, and boost team accountability. And all in one easy-to-use platform.

Tervene connects your leadership team with the tools to run smoother shifts. Use it to:

- Structure daily management

- Standardize leader routines

- Capture frontline insights

- Lead better meetings

It’s built to help you fix issues before they grow.

Still, with so many tools and features out there, how do you know what’s right for your team?

How do you choose the right operator rounds tool?

Picking the right tool doesn’t have to be difficult. All you need is to focus on your needs, ask the right questions, and involve the people who’ll actually use the tool.

Start by asking vendors smart questions:

- How easy is it to use on the shop floor?

- Can it work offline?

- How does it handle photos, comments, or issue tracking?

- Does it integrate with our current systems?

- What does onboarding and support look like?

You’ll want tools that are simple, flexible, and actually work for frontline teams, not just for management.

Start with mobile device access and digital checklists. These benefits make it easy for operators to log tasks, flag issues, and stay on track—all from a phone or tablet. No more digging through paperwork or chasing down lost forms.

Real-time issue tracking is another must. When something goes wrong, you want to know right now, not at the end of the shift. The faster you catch problems, the faster you can fix them.

Clear dashboards and reporting help you see what’s really going on. You’ll spot trends, track progress, and make smarter decisions without having to dig through messy spreadsheets.

As we mentioned earlier, look for tools that integrate with your CMMS or EAM system. That way, your rounds feed directly into your maintenance workflow—no double entry, no dropped info, just a clean handoff.

Additionally, make sure the tool fits your process. Customization options let you tweak operator inspection checklists, workflows, and alerts to match how your team actually works, not the other way around.

And finally, involve your operators early.

They’re the ones using the tool daily. Let them test it. Ask what they like, what’s confusing, and what would make their job easier. If they’re on board, adoption will be way smoother.

And, don’t forget budget and ROI.

Consider not just the upfront cost, but the time you’ll save, the maintenance costs you’ll reduce, unplanned downtime you’ll avoid, and the efficiency you’ll gain. A good tool should pay for itself quickly.

Once you’ve picked the right solution (we hope it’ll be Tervene), it’s time to put it into action. A solid rollout plan makes all the difference.

What’s the best way to roll out new processes?

Gemba Walks: 12 Steps, Checklists & Templates

Even the best system won’t work if you rush it. Rolling out a new operator round process takes planning, patience, and strong communication. Here’s how to do it without the stress.

You need to start by mapping out key steps. Don’t flip the switch overnight. Give yourself time to:

- Review and update current checklists

- Choose and test the right tool

- Train your team

- Phase in the new process

Create a clear timeline with goals, deadlines, and who’s responsible for what. Keep it realistic. A rushed rollout usually leads to confusion and pushback.

A plan’s no good without training.

Training should be simple, hands-on, and role-specific. Show operators exactly how the new process helps them, not just the company. Short sessions, job aids, and quick follow-ups can go a long way. And don’t forget about supervisors—they need to lead by example.

Even with training, change can be tough.

Expect some pushback, especially if people are used to the old way. Be open. Ask for feedback and listen. Explain the “why” behind the change—fewer breakdowns, less paperwork, and an easier workday. Highlight early wins and celebrate them.

Want to ease into the change? Start small.

Choose one area, team, or shift to test the new process. Gather feedback, make improvements, and build confidence before expanding. A phased rollout lets you fix issues early and build momentum.

After rollout, it’s time to check what’s working.

How do you measure success? Operator rounds best practices

You’ve rolled out your new operator rounds. Now, how do you know it’s working? Success isn’t just about checking boxes. It’s about real improvements on the floor. The key is tracking the right numbers and staying open to ongoing feedback.

To measure progress, compare a few simple metrics from before and after the change. Look at:

- Round completion rate

- Number of issues logged

- Response time to fix problems

- Equipment downtime

- Repeat issues on the same assets (and overall performance of assets)

These give you a quick snapshot of how things are going.

Beyond the KPIs, pay attention to what’s actually changing on the floor. Are your operators spending less time buried in paperwork? If the process is smoother and faster, that’s a win.

Check in with supervisors, too. Are they getting cleaner, more accurate reports without chasing people down or guessing what happened during a shift? That’s a good sign that your rounds are more reliable.

And what about your maintenance team? If they’re catching issues earlier and fixing things before they break, your new process is doing its job.

If day-to-day work feels smoother and fewer things are slipping through the cracks, that’s real success.

Still, don’t just set it and forget it. Check in regularly with your team. Ask:

- “What’s working well?”

- “What’s slowing you down?”

- “What would you change?”

Use this feedback to tweak your process. Keep improving over time. You’ve built a better process; now what? Let’s look at where operator rounds are headed next.

What’s next for operator rounds?

Operator rounds are changing fast, and the future looks smart, connected, and more efficient than ever. If you want to stay ahead, it helps to know what’s coming next.

You’ll see more companies moving from paper to fully digital, if they haven’t already. But it doesn’t stop there. Look out for:

- More mobile-first tools for real-time reporting

- Standardized data across shifts and teams

- Easier access to insights for managers and operators alike

Everything is moving toward faster decisions and fewer surprises on the floor.

Some of the biggest shifts will come from tech. AI is already helping predict equipment failures. In the future, it’ll go even further, flagging potential issues before anyone notices them. Automation will handle routine data collection, while robots may assist with rounds in hard-to-reach or hazardous areas.

But don’t worry! These tools won’t replace operators. They’ll support them. You’ll still need sharp eyes, quick thinking, and human judgment. The tech just helps you focus on what matters most.

The best way to keep up with change? Get ready now.

Start small: embrace digital tools like Tervene, encourage learning, and get your team comfortable with change. The more adaptable your process is now, the easier it’ll be to plug in new tech later.

Also, invest in people. Give your frontline teams the training and tools they need to grow alongside the tech.

So, for now, you’ve got the tools, the plan, and the vision. Let’s wrap it all up with some final thoughts and your next steps.

Final thoughts: where to start today?

Streamlining operator rounds is all about doing things better. With the right approach, you’ll save time, reduce downtime, and make life easier for your team.

Let’s quickly recap what you’ve learned in this guide:

- Operator rounds are key to catching issues early and keeping operations smooth.

- Inefficiencies are often hiding in plain sight—track them, measure them, fix them.

- Tools like mobile apps, IoT, and AI can make a big difference.

- Choose solutions that fit your team, involve your operators early, and deliver measurable value.

- Rollouts work best when you plan, train, and start small.

- Success comes from continuous improvement and listening to your team.

Now it’s your turn. Don’t wait for the “perfect” time to start. Pick one area of your current process and take the first step. Even a small change (like switching from paper to a mobile checklist) can have a big impact.

To make the process easier, try Tervene. It’s built for frontline teams, combining:

- Digital checklists

- Gemba Walks

- Issue tracking

- Team communication

- Actionable insights

Plus, all these things are in one place. It’s a great way to simplify your rounds without sacrificing quality or control.

And finally, keep learning. Explore other tools, talk to your team, and keep refining your process. Operator rounds aren’t just a task—they’re a chance to build a stronger, smarter operation.

You’ve got what you need. Now go make it happen

Gemba Walk Software

More Articles From Our Experts

Boost efficiency, quality, and safety with Gemba Walks—see how leaders solve problems on the floor with real-world examples and structured approaches.

Here’s the Ultimate Leader LSW Handbook. Drive Lean leadership efficiency and ensure operational excellence at all management tiers.

Uncover how a Daily Management System can elevate operational excellence and boost team efficiency in our comprehensive guide.

FAQ: Streamlining operator rounds in 2025

Operator rounds are routine inspections performed by plant operators to check equipment, monitor performance, and identify potential issues early. These rounds help ensure workplace safety, reduce downtime, and improve operational efficiency.

In 2025, labor shortages, rising maintenance costs, and tighter production schedules make it essential to streamline operator rounds. A modernized, efficient process helps plants work smarter — not harder — and keeps operations running smoothly.

Common signs of inefficiency include inconsistent reporting, missed issues, too much paperwork, delayed problem resolution, and low morale. Gathering operator feedback and tracking key metrics like completion rates and downtime can help you identify what needs improvement.

Mobile apps for digital checklists, IoT sensors for real-time equipment monitoring, AI for predictive maintenance, and integration with CMMS/EAM systems all help streamline and modernize operator rounds.

Look for tools that are easy to use on the shop floor, work offline, support real-time issue tracking, integrate with your existing systems, and can be customized for your team’s workflows. Involve operators in the selection process to ensure adoption.

Plan your rollout carefully: update current checklists, test tools, train your team, and phase in changes. Start small, gather feedback, and continuously improve based on operator input and performance data.

Track metrics like round completion rates, number of issues logged, response times, equipment downtime, and repeat problems. Monitor improvements in operator efficiency, communication, and overall workplace safety.

Operator rounds are becoming more connected, data-driven, and mobile-first. Expect more AI-powered insights, standardized processes across teams, and tools that help operators and managers make faster, smarter decisions — all without replacing human judgment.