- The systematic eight-step problem-solving approach embedded in FMDS delivers thorough analyses and sustainable solutions, moving organizations away from quick fixes to lasting improvements.

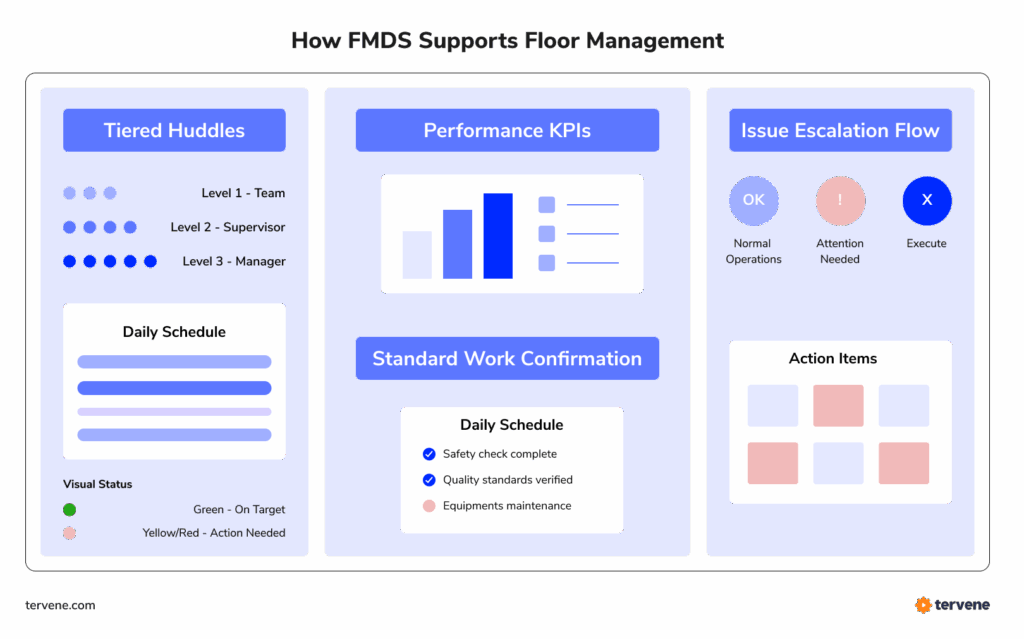

- Visual management tools and daily huddles allow for quick communication and decision-making. At the same time, standardized work processes create the consistency needed for continuous improvement.

- The digital transformation of FMDS improves traditional approaches by delivering real-time updates, remote access, and sophisticated data analysis, resulting in better-informed operational decisions.

Achieving efficiency in manufacturing requires companies to think beyond quality equipment and skilled workers. While these elements may be essential to the efficiency equation, the challenge lies in orchestrating them into a harmonious operation. Many organizations struggle with inconsistent processes, poor visibility, and reactive problem-solving approaches.

Floor Management Development Systems (FMDS) have emerged as a solution, providing frameworks that standardize processes, enhance communication, and drive continuous improvements. This article explores how FMDSs transform manufacturing operations, the technologies involved, and how platforms like Tervene deliver new operational efficiency levels.

What is an FMDS, and what does it stand for? Meaning explained

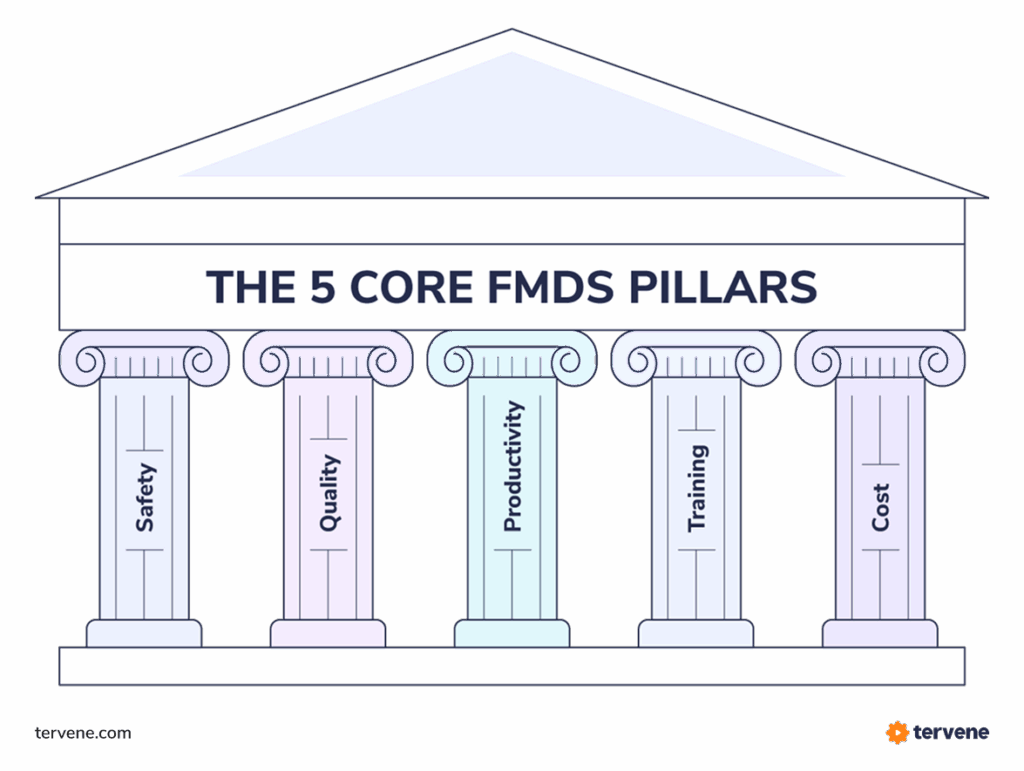

FMDS stands for Floor Management Development System. At its core, an FMDS is a structured approach that develops skills within middle management while simultaneously providing standardized methods to manage production areas. You can think of it as the nervous system of a manufacturing operation—collecting signals, processing information, and coordinating responses across the entire organization.

An FMDS’s primary strength is its ability to offer new levels of visibility into daily operations. When designed and implemented correctly, FMDSs allow managers to spot issues quickly and deploy solutions before they expand into larger problems. This proactive approach is a major departure from traditional reactive management styles.

Rather than operating as a standalone tool, an FMDS integrates visual management, standardized work processes, and systematic problem-solving methodologies into a cohesive system. This integration ensures that every aspect of the operation works together toward a defined, usually efficient goal.

What truly sets an FMDS apart, however, is its emphasis on process management and employee development. To create a sustainable foundation for continuous improvement, FMDSs build capability throughout an organization’s hierarchy, extending beyond simple performance metrics.

The evolution and importance of FMDS: Toyota’s origin

FMDS’s journey from its roots in Japanese manufacturing principles (similar to Kamishibai visual management) to its current status as a global standard is a testament to its enduring value. These systems have evolved from Lean methodologies to meet the increasingly complex demands of modern manufacturing environments. What began as a simple visual management tool has transformed into a sophisticated system that drives operational excellence across numerous industries.

More than just delivering efficiency, an FMDS provides the structural backbone for businesses to maintain consistency while remaining agile. As market demands fluctuate, these systems offer the framework needed to maintain quality and efficiency while adapting to change. This potent combination of stability and flexibility has earned FMDSs a permanent seat at the modern manufacturing table.

The core principles of effective floor management

Standardization is essential for effective floor management. It provides a consistent baseline for measuring improvements and helps identify variations that could impact product quality or efficiency.

Visual management simplifies complex operational data into clear visuals, allowing managers to assess the state of operations and make informed decisions quickly.

Regular Gemba walks enable leaders to gain firsthand insights by observing work processes, fostering employee engagement, and providing immediate feedback.

Leader Standard Work templates ensure consistent management by providing structured routines and accountability, allowing leaders to focus on strategic priorities.

Employee involvement is crucial; engaging workers in problem-solving taps into their valuable knowledge and experience, driving continuous improvement.

Industry leaders leverage Tervene to implement FMDS

The eight-step problem-solving method in FMDS

The Eight-Step Problem-Solving method is a structured, team-based approach to identifying, analyzing, solving, and preventing operational problems.

- Step 1: Problem clarification ensures that everyone understands the issue at hand.

- Step 2: Breaking down complex issues into manageable parts helps teams address problems without feeling overwhelmed.

- Step 3: Setting clear targets gives direction and motivation for improvement; these targets should be specific, measurable, and aligned with organizational goals.

- Step 4: Root cause analysis focuses on identifying the fundamental sources of issues instead of just addressing symptoms.

- Step 5: Teams design countermeasures to prevent the problems from recurring.

- Step 6: Implementing countermeasures requires careful planning to ensure solutions address root causes without creating new problems.

- Step 7: The monitoring phase provides feedback on solution effectiveness, comparing results against established targets to maintain accountability.

- Step 8: Finally, standardizing successful solutions prevents regression and ensures improvements are integrated into the organization’s operations.

Visual management board and communication in FMDS

When implementing an FMDS, visual management boards are key points for important information and decision-making. They convert abstract data into clear visuals that team members can easily understand and act on. Positioned in high-traffic areas, these boards ensure that critical information remains visible.

Daily huddles around these boards are essential in the FMDS framework. These brief sessions—typically 15 minutes—bring teams together to share updates, identify issues, and create action plans. They promote efficiency and ensure that every voice is heard.

Using color-coding and visual cues creates an immediate language that overcomes communication barriers. Red indicates urgent issues needing attention, while green signals smooth operations. This obviousness allows for quick responses, especially in high-pressure situations.

The benefits of implementing FMDS in manufacturing

The impact of FMDS on productivity is clear. Standardized work procedures reduce variability and waste, while systematic problem-solving reduces downtime. These enhancements and optimized resource use lead to significant operational cost savings.

Quality control improves dramatically with FMDS implementation. The systematic approach to identifying and resolving problems catches issues early, reducing defects and rework. This proactive quality management results in fewer customer complaints and a stronger brand reputation.

As Simon Rochette notes from his extensive experience at Tervene,

Rochette also emphasizes how an FMDS “creates more accountability across teams, which makes follow-up easier, and drives a stronger problem-solving culture.”

Employee engagement also rises when workers see their contributions making a real difference. Involving team members in problem-solving and continuous improvement fosters a culture of ownership, which reduces staff turnover and strengthens team cohesion.

Moreover, the accurate data provided by FMDS enhances decision-making at all levels. This improved visibility enables faster, more informed decisions aligning with operational needs and strategic objectives.

Overcoming challenges in FMDS implementation

As beneficial as FMDSs are, they face significant challenges, particularly resistance to change during implementation. Even the best-designed system can fail without user buy-in. Success hinges on strong leadership commitment, clear communication about the system’s benefits, and well-planned strategies that allow teams to adapt gradually to new workflows.

Another common issue is maintaining consistency across shifts and departments. Standardized training programs are essential to ensure all team members understand their roles. Regular audits and reliable management accountability systems help uphold standards and pinpoint areas needing extra support.

Sustaining momentum after initial implementation is also a challenge. To prevent regression to outdated practices, ongoing reinforcement through regular review meetings and recognition of achievements is crucial. Companies should view an FMDS as a fundamental change in operational ethos, not just a project with an end date requiring continuous nurturing.

Standardize and structure management activities with Tervene’s tools

What are the key performance indicators for FMDS?

Safety metrics

Safety metrics are the most critical FMDS performance measurement. Tracking incident rates, near misses, and hazard identifications provide valuable insights into the effectiveness of safety protocols and highlights areas requiring immediate attention.

Quality indicators

Quality indicators come in second, verifying that process improvements are translating into tangible benefits for end users. Organizations can monitor defect rates, first-pass yield, and customer complaints, all providing early warning signals should standards begin to slip.

Productivity KPIs

To quantify the impact of FMDS initiatives and identify opportunities for further optimization, productivity KPIs offer concrete evidence of operational improvements. These measurements help justify continued investment in improvement efforts.

Employee development metrics

These metrics complete the picture by ensuring that workforce capability continues to grow. Tracking training completion, skill progression, and participation in improvement activities helps organizations maintain the human resources needed for outstanding performance.

FMDS 2.0: The technologies driving modern FMDS design

Digital FMDS platforms have dramatically surpassed traditional paper-based systems by offering interactive, real-time tools accessible anywhere in a facility—or the world. These platforms vastly improve visibility and accelerate decision-making by providing immediate access to vital operational data and performance metrics.

Integrating IoT sensors and connected equipment has transformed data collection from a manual chore into an automated process. This digital leap has reduced errors and enabled predictive maintenance that can prevent costly breakdowns before they occur.

With advanced data analytics revealing improvement opportunities and mobile applications liberating FMDS users from the constraints of physical locations, the door is now wide open for manufacturers to boost their operational procedures—and their profitability fundamentally.

Boost your operations with Tervene's FMDS tools

Tervene provides a comprehensive digital platform to help frontline managers and operational leaders standardize routines and drive continuous improvement.

- Define, implement, and track daily, weekly, and monthly management routines with Leader Standard Work (LSW) software to ensure consistent operational execution.

- Enable a powerful Daily Management System with digital tools that support Gemba walks, team huddles, and structured meetings.

- Digitize safety, quality, and equipment checklists to provide the resources frontline teams need to conduct inspections and audits directly from mobile devices.

- Drive operational excellence with software that delivers structured problem-solving, systematic issue tracking and prioritization, and visual dashboards for informed data-driven decisions.

Not ready to go digital?

FAQ about FMDS (Floor Management Development Systems)

FMDS stands for Floor Management Development System. It’s a structured framework designed to standardize daily management routines, enhance operational visibility, and support continuous improvement in manufacturing environments.

An FMDS improves operational efficiency, reduces downtime, enhances quality control, boosts employee engagement, and drives a culture of continuous improvement through standardized processes and proactive problem-solving.

FMDS integrates an eight-step problem-solving method that helps teams clarify issues, identify root causes, implement countermeasures, and sustain improvements—moving from reactive fixes to lasting solutions.

Visual management boards display key operational data, enabling fast, transparent communication. Combined with daily huddles, they support quick decision-making and help teams stay aligned on priorities and performance.

Typical challenges include resistance to change, inconsistent adoption across shifts, and sustaining momentum post-implementation. Success depends on leadership commitment, proper training, and ongoing reinforcement of best practices.

Key performance indicators include safety metrics (incident rates), quality indicators (defect rates), productivity KPIs (output per hour), and employee development metrics (training completion, skill progression).

FMDS 2.0 refers to the next generation of digital FMDS platforms that leverage IoT, mobile apps, real-time data, and advanced analytics—offering greater visibility, faster decision-making, and higher levels of operational excellence.