Master the Gemba Walk: Essential Checklists & Questions

| Audience: | Manufacturing and Healthcare Executives, Lean Management and Continuous Improvement Professionals, Operational Leaders and Safety Officers |

| Last updated: | August 7, 2025 |

| Read time: | 11 mins |

- Gemba Walk checklists are essential for standardized process improvement.

- Practical checklists should be tailored to specific roles and focus on key performance indicators.

- Implementing a Gemba Walk culture can increase efficiency, improve quality, and enhance employee engagement.

Understanding the meaning of a Gemba Walk

Anyone who’s ever worked in a process-heavy environment like manufacturing is well aware that, unfortunately, issues rarely show up early in neat, comprehensive reports. Usually, by the time they’re discovered, it’s too late.

For this reason, numerous Lean practitioners implement an effective and straightforward principle to tackle this — visit the Gemba, in other words, the actual place where work is done.

A Gemba Walk isn’t your average factory floor walk. It’s a purposeful practice where executives leave the office to observe how things truly function, speak with the workers, and identify opportunities that they would never notice on a dashboard.

Fundamentally, this framework is based on three simple concepts:

- Go and See – Observe all processes in real time, directly where the work takes actual place, rather than assuming how they work based on metrics and results.

- Ask Why – When something feels off, engage directly with frontline workers who know the job best, and dig into the “why”, instead of simply treating surface-level symptoms.

- Show Respect – Acknowledge frontline expertise, listen to feedback, and involve teams in identifying improvement opportunities.

The majority of businesses use Gemba Walks in an attempt to simultaneously enhance performance and foster a culture of continuous improvement.

When conducted regularly, these walks build employee trust, reveal minor inefficiencies before they snowball into costly problems, and produce noticeable improvements in productivity, quality, and safety.

And when Gemba Walks are combined with a structured checklist, teams stop relying on memory or gut feeling. Instead, every visit becomes a repeatable system for spotting problems, fixing them early, and keeping operations sharp and efficient.

What is a Gemba Walk checklist?

A Gemba Walk checklist is a form with questions and points of inspection that team leaders, managers, and executives use during their Gemba Walks. Thanks to its structured approach, team leaders, managers, and directors go to the workplace (or Gemba in Japanese) to identify inefficiencies, gather insight, and engage with frontline employees.

These checklists assist whoever carries out the Gemba Walk every step of the way, ensuring that everything is being reviewed and optimized.

Gemba Walk Checklists aim to generate improvement opportunities and to proactively identify issues before they impact production (Quality, Health and Safety, and Productivity).

Gemba Walk Checklists help managers to:

- Observe Processes: Systematically assess the performance of tasks.

- Detect Issues: Identify potential problems and deviations from standards.

- Engage with Employees: Actively involve and question frontline workers.

- Spot Improvement Opportunities: Seek ways to optimize processes and enhance efficiency.

- Document information: Collect observations, annotate, and take photos.

The great thing about Gemba Walks is that they’re applicable across all industries. For instance, in healthcare, Gemba Walks help ensure that patient safety protocols, staff workflows, and operational efficiency are continually monitored and improved.

The importance of standardized checklists

When not standardized, Gemba Walks may yield inconsistent outcomes. Without a structured checklist, managers conducting spontaneous Gemba Walks may address the first issues they stumble upon. This approach can vary widely depending on who is performing the walk.

Bringing consistency

However, standardized checklists bring consistency. Standardized questions establish consistent operational control for all departments, shifts, and production units. This consistency also streamlines training new supervisors and managers who can follow the procedure.

Enhancing support for frontline workers

Standard Gemba walks are a powerful tool that empowers frontline workers. When they encounter a potential issue, they can confidently wait for their supervisor’s scheduled Gemba Walk, knowing that the standardized questions will address their concerns.

This structured approach ensures steady and reliable support throughout the day, facilitating clear communication and giving workers a sense of control over their work environment.

Gemba Walk checklists promote control and facilitate Leader Standard Work while ensuring frontline workers receive the support they need.

Familiarizing yourself with key questions

A Gemba Walk isn’t a test or an evaluation of the workforce; instead, it is a collaborative method centered around assessing worker availability, job planning, materials, equipment, and information. By being well-acquainted with the critical questions used for validation, frontline workers and team leaders become active agents in the Gemba Walk process, fostering a sense of engagement and ownership.

Workers must understand that their supervisors conduct Gemba Walks to assist them in finding solutions rather than as a means of punishment. This comprehension fosters greater adherence to this valuable practice, encouraging open communication and collaboration across the entire organization.

What do Gemba Walk checklists help validate?

The manager’s role involves validating elements affecting key performance indicators tied to the organization’s objectives. This proactive approach includes improving workplace safety, reducing customer complaints, minimizing rework, and meeting delivery goals.

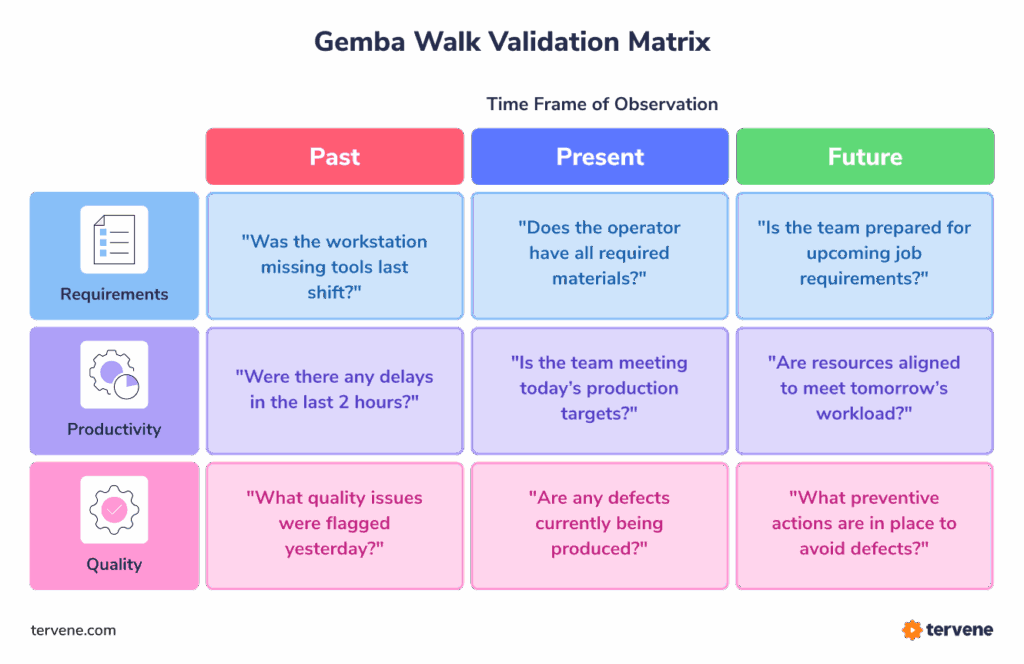

Identifying issues at various time points:

- Past Issues: This phase involves formulating questions to prevent the recurrence of past problems.

- Current Issues: This phase focuses on immediate action, issue resolution, task assignment, and information sharing with relevant stakeholders.

- Future Issues: This phase emphasizes preventive measures to avert potential problems.

Question formulation depends on the following:

- Time frame: Past, Present, or Future.

- Category: Requirements, Productivity, Quality.

- Subject: Workers, Information, Material, Equipment.

Gemba Walk checklists are used by managers to verify all the elements that have a direct impact on KPIs, such as process stability, equipment reliability, and workforce readiness. Not only does a structured walk uncover what’s working and what’s not, but it also shows whether daily operations are actually meeting the standards your team has set.

Checking 5S during Gemba Walks

One of the simplest ways to confirm that standards are being followed on the shop floor is by observing 5S compliance— Sort, Set in Order, Shine, Standardize, and Sustain.

Managers can evaluate these standards during Gemba Walks in real time by looking for 5S indicators like tools returned to their designated spots, workstations free of unnecessary items, and visual labels or markings being followed.

Consider integrating a 5S system into your Gemba Walks as a set standard for keeping workstations organized, safe, and efficient.

This ensures that all tools, materials, and equipment are exactly where they should be, and helps prevent small inefficiencies or safety risks from turning into larger production problems down the line.

Industry leaders leverage Tervene to structure their Gemba Walks

Choosing the best Gemba Walk questions

Begin by identifying the specific deviations from the standard you aim to uncover. Next, formulate questions that facilitate the identification of issues, data collection, process evaluation, and employee insights. To ensure the relevance of the potential problems raised, focus on their actionability – their potential for actionable steps.

Ensure that:

- Questions are aimed at finding solutions rather than assigning blame.

- Questions pinpoint pertinent deviations.

- Potential issues directly affect the organization’s key performance indicators.

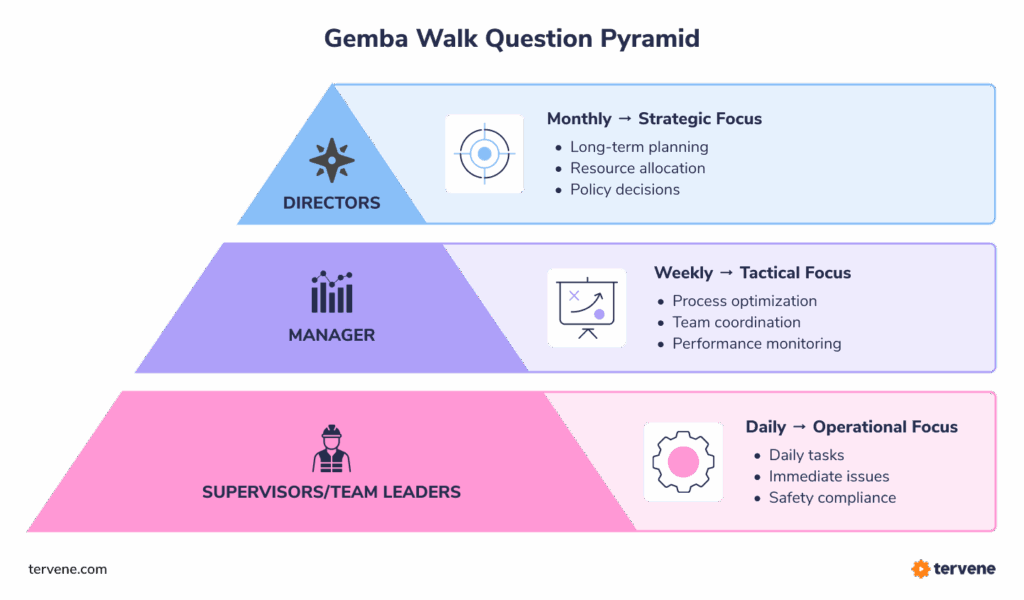

Examples of Gemba Walk questions for each role

It’s crucial to tailor Gemba Walk questions to the specific roles of the individuals executing them. This alignment with the responsibilities and concerns of each position within the organization not only makes the process more effective but also makes each team member feel valued and integral to the process.

For instance, team leaders focus on immediate issues and team productivity, production managers address operational aspects, and executives oversee strategic objectives.

Here are some examples of Gemba Walk questions for different roles.

Gemba Walk checklist for team leaders

- “Have there been any unforeseen quality-related problems in the past two hours?”

- “Are Health and Safety standards upheld?”

- “Is the worker at his station?”

- “Is the 5S standard respected?”

- “Does the production rate follow the schedule?”

- “Does the worker know the next priority?”

- “Does the employee have all the required tools for the next task?”

- “Are there any other issues to address?”

Gemba Walk checklist for managers

- “Are there any issues to transfer to a higher management level?”

- “Have there been any unforeseen quality-related problems in the past two hours?”

- “Is the equipment working properly? Does it need maintenance?”

- “Does the department need more people for the next job?”

- “Is the 5S standard being maintained? Are there any suggestions for improvement?”

- “Is the team leader aware of the priorities?”

- “Are we meeting our overall production targets for the day/week?”

- “Are there any other issues to talk about?”

- “Did the team leader perform his two Gemba Walks?”

Gemba Walk checklist for executives and directors

- “Are Health and Safety standards respected?”

- “Could we reduce waste?”

- “Are there any critical issues or obstacles affecting our strategic goals?”

- “How well are we aligning our operational practices with corporate objectives?”

- “Are we investing in the right technology and resources to stay innovative?”

- “What measures are in place to foster a culture of continuous improvement? Are they effective?”

- “Is our overall performance meeting key performance indicators (KPIs)?”

Each role’s dedicated checklist ensures that the correct issues are addressed, enabling the organization to meet its goals effectively at different management levels. Much like operator rounds, this approach promotes a more systematic and comprehensive presence of all levels of management on the shop floor.

Download free Gemba Walk checklists and templates

Gemba Walks: 12 Steps, Checklists & Templates

How many questions should supervisors go through?

The number of questions on the Gemba Walk checklist is optional as long as the entire process can be completed within 15 to 25 minutes. Too many questions on the list can overwhelm leaders, making it challenging to identify all issues effectively. Keep the questions concise and impactful.

Additionally, when discussing identified problems with workers, it’s recommended to inquire about the “what,” “why,” and “how” aspects. It’s more effective to ask fewer, broader questions and delve deeper into your understanding of the issues.

Relevant Tervene solutions

Implementing a Gemba Walk structure in manufacturing

As previously mentioned, the main goal of implementing Gemba Walks is to create a structured routine that becomes ingrained in daily operations, not just to walk the shop floor and observe.

In order to guarantee that every team and manager maintains a consistent strategy over time, here’s a quick rundown of the key steps to establish a systematic Gemba Walk structure within an organization:

- Update the Organizational Chart: Ensure your company’s organizational chart is current and accurately represents your team’s structure.

- Introduce the Gemba Walk: Conduct an introductory meeting to present and explain the Gemba Walk to the team.

- Develop Gemba Walk Checklists: Create specific checklists tailored to each role and your objectives.

- Establish a Regular Schedule: Set a consistent, recurring schedule for Gemba Walks to ensure they happen at planned intervals and to promote Leader Standard Work.

- Individually Shadow Team Leaders: Take the time to shadow each team leader individually during their first Gemba Walks to allow for observation and support.

- Schedule Improvement Meetings: Organize follow-up improvement meetings to discuss findings and develop action plans.

- Sustain the Gemba Walk: Implement measures (feedback mechanisms, standardized documentation, etc.) to ensure your process’s ongoing effectiveness and sustainability.

Once the structure is in place — roles are assigned, teams are trained, and checklists are ready, each individual Gemba Walk follows its own process, which we’ll cover next.

Steps in a Standard Gemba Walk Process

Every Gemba Walk adheres to a set procedure that keeps the visit focused and actionable. While the implementation plan sets the stage, these steps describe what truly occurs during each shop floor walk:

- Plan the Walk – Decide on the location, timing, and key focus points for the visit.

- Go to the Gemba – Visit the site to see how processes are running in real time.

- Engage with Employees – Ask questions, gather feedback, and understand the “why” behind what you observe.

- Document Observations – Capture notes, photos, or digital checklist entries for follow-ups.

- Follow Up on Findings – Assign actions, escalate issues when needed, and ensure all improvements are tracked.

Every step makes the walk measurable and purpose-driven, transforming random observations into a repeatable cycle of improvement.

Benefits of digital Gemba Walks

Digital Gemba Walks ensure consistent and accurate data capture, fostering a culture of continuous improvement and operational excellence.

Features like mandatory questions and automated follow-up actions streamline issue tracking and the implementation of improvements. Customizable digital checklists offer flexibility and support data-driven decision-making, allowing teams to access historical data, address issues proactively, and drive sustainable productivity improvements.

By automating routine tasks and providing real-time insights, Digital Gemba Walks empower teams to make informed decisions faster, resulting in more efficient workflows and higher overall performance.

Real-World impact: Safran's success

Safran Cabin Canada showcases how Gemba Walks can propel tangible improvements. They’ve embraced the practice by requiring multiple Gemba Walks daily. The first walk directly informs their daily meetings and calls for immediate action.

Also, frontline managers are tasked with conducting a deeper analysis of at least one issue daily by utilizing tools like Quick Response Action Plans, 5 Whys, or A3 problem-solving. This thoroughness ensures that problems identified during Gemba Walks are actively addressed through structured problem-solving and resolution plans.

Watch this video to see how Safran Cabin Canada (formerly Zodiac Aerospace) leverages Tervene’s full potential.

Tervene’s Gemba Walk solution

Tervene’s mobile solution streamlines and automates Gemba Walks, enabling organizations to create standardized checklists that enhance operational control.

With features like real-time data capture, task tracking, and issue assignment, Tervene empowers managers to proactively identify issues, take immediate action, and resolve problems more effectively.

This not only boosts operational efficiency but also fosters a culture of continuous improvement across all levels of the organization — exactly what Gemba Walks are designed to achieve.

FAQs about Gemba Walk checklists & questions

A Gemba Walk checklist is a structured form managers use to guide their observations and interactions during Gemba Walks. It contains specific questions and points of inspection to ensure consistency and effectiveness in identifying issues and driving improvements.

Standardized checklists help to maintain consistency across different teams, shifts, and production units. They ensure that all managers are addressing the same critical areas, promoting operational control and facilitating Leader Standard Work, thereby enhancing your sense of responsibility and control.

When creating questions, remember that you are empowering yourself to directly impact your organization’s key performance indicators. Ensure that the questions are actionable, solution-oriented, and relevant to the specific role of the person conducting the Gemba Walk.

Some common mistakes include:

- Conducting Gemba Walks too infrequently or irregularly.

- Failing to involve frontline employees in the process.

- Not following up on identified issues with corrective actions.

- Using generic checklists that are not tailored to specific roles or objectives.

The frequency of Gemba Walks can vary depending on the organization’s needs and industry. However, a good rule of thumb is to conduct them regularly, such as weekly or bi-weekly, to ensure ongoing monitoring and improvement.

The five steps of a Gemba Walk are:

- Go and See – Observe the work process at the actual place where it occurs.

- Ask Why – Engage with employees to understand the process.

- Respect People – Show respect for the people involved in the work.

- Make Improvements – Identify areas for improvement.

- Follow Up – Ensure actions are taken based on observations.

The three P’s of a Gemba Walk are:

- Process – Observing and improving the work process.

- People – Engaging with the people involved in the process.

- Place – Ensuring that the environment supports efficient work.

At the Gemba, you can expect to see real-time operations, including process flow, employee performance, and potential inefficiencies. The goal is to spot opportunities for improvement, engage with employees, and understand the root causes of issues.