Hoshin Kanri: Lean Planning Method to Align Goals and Daily Tasks

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | September 12, 2025 |

| Read time: | 8 min |

- It bridges the gap between top-level strategy and frontline execution by aligning objectives across all departments and teams.

- It follows a seven-step process that includes vision-setting, goal cascading, daily management, and regular reviews to stay on track.

- Its visual tool, the X-matrix, maps long-term goals, annual priorities, improvement projects, and KPIs, keeping everyone focused on what matters most.

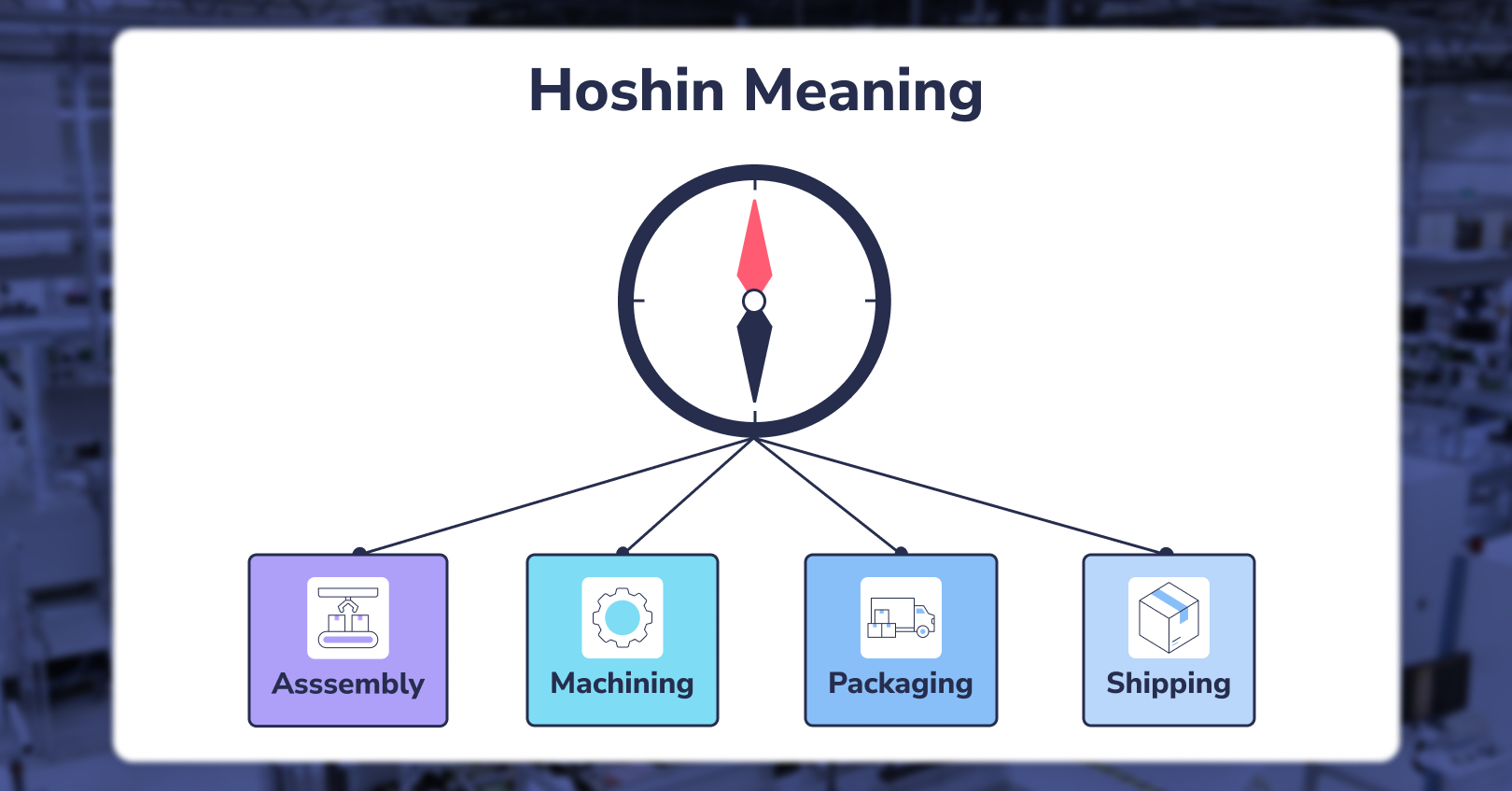

Every manufacturing leader knows how hard it is to turn a strategic, big-picture plan into actionable daily tasks. Hoshin Kanri, sometimes referred to as policy deployment, is a Lean management method that tries to close that gap. Think of it as your company’s strategic compass, making sure that everyone in the organization is working toward the same goals. In this article, we’ll explore the concept of Hoshin Kanri, how to plan and apply it in a business environment, and how modern software can streamline this process.

What Does Hoshin Kanri Mean? Definition And Examples

Hoshin Kanri is a Japanese strategic planning methodology that aligns the day-to-day efforts and long-term goals of the entire organization. Translated literally as “direction” (hoshin) and “management” (kanri), this method helps businesses clearly define the strategic direction at the top of the organizational chart and drive it down, department by department, worker by worker.

What that does is ensure that every action on the shop floor is being guided by, and striving toward, your company’s “True North” strategic objectives.

When done right, everyone, from executives to operators on the front lines, has the top goals in mind and a clear understanding of how their work drives the company toward its objectives.

You may be wondering whether implementing Hoshin Kanri is worth the trouble. Here are its key benefits:

- Precise strategic focus → priorities are clearly outlined, easing decision-making and ensuring that everyone is working toward the same goals.

- Organizational alignment → by aligning all organizational planning (sometimes referred to as “catchballs”), Hoshin Kanri ensures every department sets collective aims.

- Prioritizing resources → Hoshin Kanri makes it simple to decide what’s most important, efficiently allocating manpower and resources so there’s no wasted effort on unrelated work.

- Ongoing progress monitoring → all progress towards strategic objectives is tracked through regular monitoring to enable early responses, free from bureaucratic delay.

Hoshin Kanri has been credited by several world-class manufacturers for accomplishing astounding performance improvement. As a real-world example, when Ingersoll Rand implemented Hoshin Kanri as its operational management system, they reported significant waste cut down and stronger organizational alignment, where all workers clearly understood how their efforts were contributing to the overall company success.

Through aligning its people, processes, and projects using Hoshin planning, Ingersoll Rand experienced rapid growth, and this is just one of many examples.

What Is The Hoshin Kanri Execution Process?

The great thing about Hoshin Kanri is that its planning and management methodology is flexible enough to be applied to various organizations. Generally speaking, Hoshin planning can be illustrated as a seven-step cycle, with each step playing a key role in the company-wide strategy development:

- Establish the vision and assess current state: Define your ideal future vision (5+ years), and use that as your core foundation for the entire Hoshin Kanri strategy, it’s your company’s “True North”. Next, it’s time to conduct a thorough and objective review of where you stand today as a company, evaluating existing plans, baseline performance, and ongoing processes to ground your strategy in reality.

- Set breakthrough objectives (3–5 year goals): Choose a handful of challenging, high-impact objectives that will significantly grow the business 3-5 years down the road. Breakthrough objectives have to push the business to higher performance (e.g., new market growth, doubling output) and usually coincide with Lean or Six Sigma initiatives for radical change.

- Develop one-year objectives: Divide those breakthrough objectives into concrete “stepping stone” year-long goals for the near future. You want to ask yourself: What must we accomplish during the year to put us into place for our 3–5 year vision? These must be clear, quantifiable goals, for instance, “boost on-time delivery to 98%” or “cut defect rate by 50%”, each bringing you one step further toward the breakthroughs.

- Align all goals to teams: Allocate those annual goals throughout the entire firm. Each division, department, and team should have clear set goals with an understanding of how they relate to the strategic, organization-wide mission. This is the stage where the master plan gets cascaded down into actionable tasks. A culture of manager-employee open communication is set in place for creating aligned priorities so everyone understands what they have to do in order to achieve each set of goals.

- Execute with daily management: Now it’s time to start putting those plans into action. Every person in the organization, from manufacturers to line managers, works on their assigned day-to-day tasks in the direction of those year-end objectives. This generally involves using the various Lean methods, such as Kaizen events, PDCA problem-solving, etc. It’s crucial here that progress is periodically monitored (with dashboards, huddles, specialized software, etc.), to ensure consistent alignment with strategic objectives.

- Monthly progress reviews: Leadership requests progress summaries from all departments at the end of each month to determine whether each process is still fully aligned with the 1-year plan and the long-term vision. These milestones implement a habit of accountability, driving team motivation, and removing any new obstacles that may have come up.

- Annual review and adjustment: At the end of the year, it’s time to conduct a thorough, general audit of your performance against the initially set plan.

If the company met its targets — it moves toward setting new goals for the next year. If not — it must analyze what went wrong and why, and alter the necessary approach and processes, keeping the strategic plan dynamic and responsive.

Companies can seamlessly modify each step, but the main process remains the same: plan → do → check → act, company-wide.

An increasing number of companies leverage specialized automation tools to digitize and implement the Hoshin Kanri framework into their operations. For instance, here’s how Tervene helps Manac plan and monitor their day-to-day operations and long-term objectives:

Industry leaders use Tervene to plan and manage projects more effectively

What Is the Hoshin Kanri Japanese Way Planning Matrix?

To have the Hoshin plan top of mind and ensure everyone is on the same page, businesses generally use the Hoshin Kanri X-matrix, a one-page strategic planning diagram. The diagram aims to concisely condense the key points of the Hoshin plan into a single diagram separated into four easy-to-read quadrants (making the “X” shape), which contain:

- Long-term objectives: 3-5 year or more breakthrough goals. This bottom-right box (usually the “South” of the X) identifies the grand strategic, long-term goals of the organization.

- One-year goals: These are annual goals for the current year, derived from the strategic, 3 to 5-year mission. This left-hand (or “West”) section of the diagram shows what you have to accomplish in the year as you move toward the long-term vision.

- Top-level priorities: Important projects, ventures, or core areas of focus that would help achieve the one-year objectives. This is the top quadrant (“North”) that identifies what significant ventures or alterations the business would undertake to attain those goals.

- Improvement metrics: This is the “East’ quadrant, which entails precise, measurable goals and key performance indicators (KPIs) to track the success of ongoing operations (e.g. +10% yield rise).

Each quadrant of an X-matrix is linked to one another, illuminating those connections, e.g., which year goals are the foundation of which long-term goals, and which projects affect which KPIs. The very middle of the X-matrix is where the overall strategic theme or vision is described, linking all the pieces together.

In short, the Hoshin Kanri matrix clearly captures and isolates all long-term goals, short-term goals, what you’re going to do to make them happen, and what you’re going to measure them against in one visual diagram.

Turn big-picture plans into actionable, daily tasks with Tervene’s tools

Implement Hoshin Kanri Management With Tervene's Tools and Software

Manual Hoshin planning often relies on spreadsheets, disconnected meetings, and paper-based tracking. That works in theory, but in practice, it slows everything down and lacks real-time visibility. This is where modern software tools like Tervene step in.

Tervene gives manufacturers a practical way to implement Hoshin Kanri and sustain it on the shop floor. The platform connects strategy to frontline execution through structured management routines, issue tracking, and cross-team collaboration.

With Tervene, teams can:

- Standardize daily leadership practices (e.g., Gemba walks, tier meetings)

- Escalate and resolve issues fast, keeping execution aligned with goals

- Assign, track, and follow up on action plans from anywhere

- Gain instant visibility into KPIs, audits, and operational performance

In short, Tervene doesn’t just help you plan better, it helps you execute better. By centralizing strategy deployment and operational follow-up, it supports the core of Hoshin Kanri: aligned goals, continuous improvement, and a culture of accountability.

Turn goals into measurable results

FAQ – Hoshin Kanri

Hoshin Kanri, also known as policy deployment, is a Lean management method used to align an organization’s strategic goals with day-to-day operations. It ensures that every employee, from top leadership to shop floor operators, is working toward the same long-term objectives.

The Hoshin Kanri process follows a seven-step cycle: define vision, assess current state, set breakthrough objectives, establish annual goals, align goals to teams, execute with daily management, and conduct monthly and annual reviews. This structured approach creates a direct link between strategy and execution.

Key benefits include:

-

Improved strategic alignment across departments

-

Better prioritization of resources and initiatives

-

Clear performance tracking through KPIs

-

Increased employee engagement and accountability

-

A culture of continuous improvement

The Hoshin Kanri X-matrix is a one-page visual tool that maps out your organization’s long-term goals, annual objectives, strategic initiatives, and measurable outcomes. It helps teams quickly see how their work contributes to broader company success and ensures clarity at every level.

While Hoshin Kanri originated in manufacturing (notably in the Toyota Production System), its principles can be adapted to any industry that values strategic alignment, including healthcare, services, and tech companies.

Unlike traditional top-down planning, Hoshin Kanri emphasizes two-way communication (“catchball”) and ongoing feedback. It ensures that goals are not only set at the top but understood and supported by all employees through clear action plans and regular follow-ups.

Hoshin Kanri complements Lean by providing a framework for aligning improvement efforts with strategic objectives. It drives focus, reduces wasteful activity, and ensures that Lean initiatives contribute directly to business growth.

Breakthrough objectives are 3–5-year strategic goals that represent significant improvements or changes in the organization. These goals often push the business into new markets, reduce major inefficiencies, or achieve substantial performance gains.

Monthly progress reviews are recommended to track execution and solve issues early. An annual review helps evaluate goal achievement, identify improvement areas, and reset objectives for the next year.

Yes, but manual methods (spreadsheets, paper tracking, etc.) can be time-consuming and error-prone. Many organizations use digital tools to streamline goal-setting, progress tracking, and cross-functional collaboration for more effective implementation.