SQCDP: From Basics to Operational Performance

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | February 11, 2025 |

| Read time: | 7 mins |

- The five pillars of SQCDP (Safety, Quality, Cost, Delivery, and People) are interconnected, ensuring improvements in one area don’t negatively impact others.

- SQCDP boards, often digitized, provide real-time visibility into performance, facilitating data-driven decision-making and early issue detection.

- Action lists on SQCDP boards translate identified issues into concrete solutions, driving corrective actions and continuous improvement.

Daily shop floor management plays a crucial role in organizing and visualizing team performance on key indicators through tools like the SQCDP board.

One of the recurring challenges in manufacturing is balancing multiple priorities, all of which compete for attention. Striking the right balance is fundamental to achieving operational control and managing risk effectively. That’s where the SQCDP framework comes in.

What does SQCDP mean?

SQCDP boards are visual management boards used in various industries, particularly in manufacturing, to monitor and improve key performance indicators (KPIs) related to Safety, Quality, Cost, Delivery, and People. These pillars are interconnected, and the overarching goal is to ensure that improvements in one area don’t come at the expense of another.

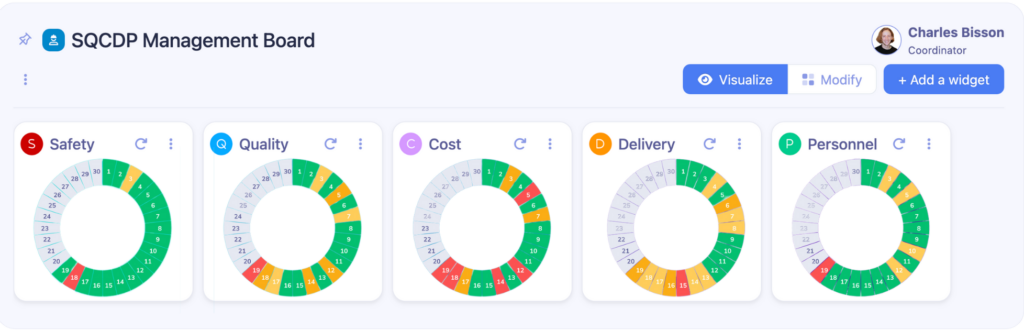

These boards are typically digitized and presented on large screens and mobile devices for easy access to information. A digital SQCDP board provides real-time metrics and data visualization, aiding in managing business performance by showcasing KPIs and streamlining work order management.

They allow managers to improve operations holistically. The result is enhanced performance, cost efficiency, and employee engagement.

The five pillars of SQCDP

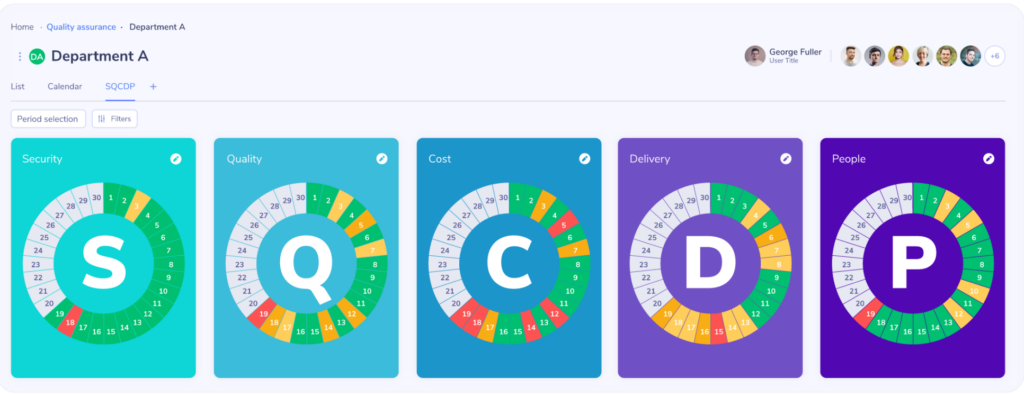

An SQCDP board is a type of Visual Management Board that helps tp visualize the five pillars (Safety, Quality, Cost, Delivery, People) of any successful and sustainable production environment. Digitized solutions draw data from various connected sources to facilitate closer collaboration and data-driven decision-making.

SQCDP boards typically include color-coded indicators determining your performance in a specific area, such as green for good, yellow for acceptable, and red for bad. It’s up to the organization to define specific targets and thresholds, and each day, the actual performance data for each indicator is compared against these predefined targets.

By visualizing these key metrics, organizations can promote transparency, facilitate cross-functional collaboration, and drive continuous improvement efforts. These key metrics help manufacturers track various aspects of their operations including safety, quality, and productivity.

Let’s take a closer look at the five pillars of SQCDP:

Safety

Workers may face hazardous conditions on the shop floor. While prioritizing safety is primarily about preventing accidents, it also ties into the other pillars of SQCDP by reducing downtime and improving productivity.

Safety-related issues often stem from insufficient training or inconsistent practices, both of which stem from poor communication. Managers must implement regular safety audits and provide hands-on training to foster a culture where safety is everyone’s responsibility. As communication is essential to achieving those goals, visual management helps support efforts by providing real-time visibility into safety metrics and potential hazards.

Example:

Green

- No safety incidents or near misses, compliance with safety protocols

Red

- Any safety incidents, near misses, or violations of safety protocols

Quality

Customer satisfaction and retention depend heavily on the quality of goods delivered. Even minor deviations in quality can lead to product recalls or regulatory penalties, which can happen at any stage of the production process.

Quality issues often stem from inconsistent processes, a lack of standardization, or insufficient training. Given the complexities of the typical production environment, it’s often difficult to pin down the root cause of quality discrepancies too. However, incorporating SQCDP boards and visualizing key quality metrics can help identify potential issues before they impact quality, thus helping managers ensure consistent outcomes.

Example:

Green

- Meeting or exceeding quality standards, low defect rates, positive feedback

Red

- High defect rates, customer complaints, non-conformance to quality standards

Cost

With the costs of raw materials and energy supplies rising constantly, cost management has become a significant priority for manufacturers. However, there’s a fine line between controlling costs and reducing costs.

If you prioritize cost reduction, you may risk undermining product quality and employee safety. Instead, it would help if you focused on maximizing value delivery by identifying and eliminating sources of waste during each stage of the production process.

Digitized SQCDP boards that integrate seamlessly with your production lines can help you monitor resource allocation and stop cost-saving measures from negatively impacting quality and performance.

Example:

Green

- Operating within budget, effective cost-saving, good resource utilization

Red

- Exceeding budget, high expenses, inefficient resource allocation

Delivery

Manufacturers face constant pressure to reduce cycle times while meeting rising demand. However, delays can happen at any production stage due to bottlenecks, workflow inefficiencies, or a lack of clear coordination between teams and external suppliers.

You need to know immediately when and where those bottlenecks arise, hence the value of SQCDP boards in tracking cycle times and ensuring that each production stage flows into the next without problems.

The best way to do that is by incorporating daily management and scheduling systems into your production processes and using real-time data to anticipate and address potential delays before they negatively impact your cycle time.

Example:

Green

- On-time delivery, meeting delivery expectations, consistent lead times

Red

- Late deliveries, missed deadlines, inconsistent lead times

People

Employees are your most valuable asset, and a well-trained and motivated workforce is vital for sustaining improvements in all the other pillars of SQCDP. Also, don’t forget that happier employees perform better, leading to higher retention rates and content customers.

Manufacturers have often struggled with high turnover rates due to problems like poor training, lack of engagement, and insufficient financial compensation. Operations managers must invest in employee development to keep morale and productivity high.

SQCDP boards help in that endeavor by supporting clear communication and making it easy for managers to track team performance, set goals, and engage workers directly in problem-solving activities.

Example:

Green

- High throughput, efficient use of resources, minimal downtime

Red

- Low throughput, high cycle times, underutilization of resources

Benefits of SQCDP

Implementing SQCDP boards offers a multitude of benefits that can significantly enhance an organization’s operational performance. By providing a clear and transparent view of key performance indicators (KPIs) and metrics, SQCDP boards improve visibility and accountability across all levels of the organization. This transparency fosters a sense of ownership among team members, driving them to take proactive steps towards continuous improvement.

One of the primary advantages of SQCDP boards is the increased efficiency and productivity they bring. By streamlining processes and eliminating waste, organizations can achieve better quality control and reduce defects. This not only leads to cost savings but also enhances customer satisfaction by delivering high-quality products consistently.

Moreover, SQCDP boards facilitate better communication and collaboration among employees. The visual management tools used in these boards make it easier for teams to understand performance trends and identify areas that need attention. This data-driven approach to decision-making and problem-solving ensures that corrective actions are based on accurate and timely information.

Employee engagement is another critical benefit of using SQCDP boards. By involving employees in the continuous improvement efforts and making them part of the problem-solving process, organizations can boost motivation and morale. This, in turn, leads to higher retention rates and a more committed workforce.

Safety is also a significant focus of SQCDP boards. By continuously monitoring safety metrics and incidents, organizations can implement measures to reduce safety incidents and create a safer working environment. This not only protects employees but also minimizes downtime and associated costs.

SQCDP boards offer a comprehensive framework for enhancing operational performance through improved visibility, accountability, efficiency, quality control, communication, and employee engagement. They support continuous improvement efforts and lean management practices, ultimately leading to reduced costs and improved customer satisfaction.

Key Performance Indicators (KPIs) and Metrics

SQCDP boards are designed to track and display a wide range of relevant key performance indicators (KPIs) and metrics, providing a comprehensive view of an organization’s performance. These KPIs are crucial for monitoring and improving various aspects of the manufacturing process.

Safety Metrics: Safety is a top priority in any manufacturing environment. SQCDP boards track metrics such as the number of safety incidents, days without incidents, and safety violations. By keeping a close eye on these metrics, organizations can identify potential hazards and take preventive measures to ensure a safe working environment.

Quality Metrics: Maintaining high quality is essential for customer satisfaction and retention. SQCDP boards monitor quality metrics such as the number of defective or nonconforming items, customer claims, and production yield. These metrics help organizations identify quality issues early and implement corrective actions to maintain consistent product quality.

Cost Metrics: Effective cost management is crucial for profitability. SQCDP boards track cost metrics such as inventory cost, waste and scrap cost, and the cost of overtime work. By analyzing these metrics, organizations can identify areas where costs can be reduced without compromising quality or safety.

Delivery Metrics: Timely delivery is critical for meeting customer expectations. SQCDP boards monitor delivery metrics such as lead time, on-time delivery, and full order fulfillment. These metrics help organizations identify bottlenecks and inefficiencies in the production process, ensuring that products are delivered on time.

People Metrics: Employees are a valuable asset, and their performance directly impacts overall productivity. SQCDP boards track people metrics such as overtime, personnel changes, and skill development benefits. These metrics provide insights into workforce dynamics and help organizations implement strategies to enhance employee engagement and productivity.

By continuously monitoring these KPIs and metrics, organizations can identify performance trends and direct improvement activities effectively. This data-driven approach ensures that decisions are based on accurate and timely information, leading to better outcomes and sustained operational performance.

Continuous Improvement and Lean Management

SQCDP boards are integral to continuous improvement and lean management practices, providing a structured approach to identifying and addressing areas for improvement. By visualizing key performance indicators and metrics, these boards enable organizations to pinpoint inefficiencies and opportunities for growth.

One of the core principles of continuous improvement is the development and implementation of action plans to address identified issues. SQCDP boards facilitate this process by providing a clear and transparent view of performance data, making it easier to develop targeted action plans. Regular monitoring and tracking of progress towards goals and objectives ensure that improvement initiatives are on track and effective.

Visual management is a key component of lean management, and SQCDP boards excel in this area. By making performance data visible and accessible to all team members, these boards foster a culture of transparency and accountability. Employees are more likely to engage in problem-solving activities when they can see the impact of their efforts on overall performance.

Root cause analysis is another critical aspect of continuous improvement. SQCDP boards support this by providing detailed performance data that can be analyzed to identify the underlying causes of issues. This data-driven approach ensures that corrective actions address the root causes rather than just the symptoms, leading to more sustainable improvements.

Employee engagement is essential for the success of continuous improvement initiatives. SQCDP boards encourage employee involvement by making it easy for them to participate in problem-solving activities and track the progress of improvement efforts. This engagement fosters a sense of ownership and commitment to continuous improvement.

In summary, SQCDP boards are a powerful tool for supporting continuous improvement and lean management practices. They provide a structured approach to identifying and addressing areas for improvement, fostering a culture of transparency, accountability, and employee engagement.

10 Visual Management Must-Haves [eBook]

Implementing corrective actions with SQCDP boards

SQCDP Boards use action lists to detail required corrective actions, assign responsible team members, and set realistic deadlines. Key performance metrics provide the data to make informed decisions by automating data collection and visualizing performance within management dashboards, and action lists ensure these decisions are translated into practical steps.

Displaying Safety, Quality, Cost, Delivery, and People metrics offers a transparent overview of operational performance. This early issue detection is necessary for timely interventions before problems escalate. The board is a central discussion hub.

Specifically, the SQCDP board:

• Identifies Issues: The board pinpoints areas needing corrective action by monitoring KPIs.

• Facilitates Discussion: The board is a central point for team meetings where issues are discussed, root causes analyzed, and potential solutions brainstormed. This collaborative approach ensures practical corrective actions.

The SQCDP Board combines metrics and action tracking to drive continuous improvement through data-driven insights and collaborative problem-solving.

Role of action lists on an SQCDP board

Action lists turn identified issues into concrete solutions on an SQCDP board. They detail specific corrective steps, assign responsible individuals, set deadlines, and outline required resources.

Regular progress updates provide transparency, allowing teams to track advancements and adjust strategies if outcomes aren’t as expected.

In short, action lists on an SQCDP Board facilitate:

- Tracking of corrective actions: They document the precise steps to address issues, assign responsibilities, set deadlines, and detail resource needs.

- Prioritization of actions: By listing actions, teams can prioritize based on urgency, impact, and available resources.

Operational Performance with SQCDP

SQCDP boards provide a comprehensive framework for managing and enhancing operational performance. By monitoring and tracking key performance indicators (KPIs) and metrics in real-time, these boards enable organizations to identify and address bottlenecks and inefficiencies in the manufacturing process.

One of the primary benefits of using SQCDP boards is the improvement in quality control. By continuously monitoring quality metrics, organizations can identify defects early and implement corrective actions to maintain consistent product quality. This not only reduces waste and rework but also enhances customer satisfaction by delivering high-quality products.

Inventory management is another area where SQCDP boards can make a significant impact. By tracking cost metrics such as inventory cost and waste, organizations can optimize inventory levels and reduce excess stock. This leads to cost savings and more efficient use of resources.

Employee engagement and productivity are also enhanced through the use of SQCDP boards. By involving employees in the monitoring and problem-solving process, organizations can boost motivation and morale. This leads to higher productivity and a more committed workforce.

Safety is a critical aspect of operational performance, and SQCDP boards help organizations improve safety by monitoring safety metrics and incidents. By identifying potential hazards and implementing preventive measures, organizations can reduce safety incidents and create a safer working environment.

SQCDP boards provide a comprehensive framework for managing operational performance. They enable organizations to monitor and track KPIs and metrics in real-time, identify and address inefficiencies, improve quality control, optimize inventory management, enhance employee engagement, and improve safety.

Best Practices and Common Mistakes

Implementing SQCDP boards effectively requires adherence to best practices and avoidance of common mistakes. Here are some key considerations:

Best Practices:

- Clearly Define KPIs and Metrics: Ensure that key performance indicators and metrics are clearly defined and aligned with organizational goals. This provides a clear focus for monitoring and improvement efforts.

- Establish a Regular Review and Update Process: Regularly review and update the SQCDP board to ensure that it reflects current performance and priorities. This keeps the board relevant and useful.

- Ensure Visibility and Accessibility: Make the SQCDP board visible and accessible to all team members. This fosters transparency and encourages employee engagement.

- Encourage Employee Engagement and Ownership: Involve employees in the monitoring and problem-solving process. This fosters a sense of ownership and commitment to continuous improvement.

- Foster a Culture of Continuous Improvement and Lean Management: Promote a culture that values continuous improvement and lean management principles. This ensures that improvement efforts are sustained and effective.

Common Mistakes to Avoid:

- Failing to Clearly Define KPIs and Metrics: Without clear KPIs and metrics, it is difficult to monitor performance and identify areas for improvement.

- Not Regularly Reviewing and Updating the Board: An outdated SQCDP board can lead to irrelevant or inaccurate information, reducing its effectiveness.

- Not Ensuring Visibility and Accessibility: If the board is not visible and accessible, it is unlikely to be used effectively by team members.

- Not Encouraging Employee Engagement and Ownership: Without employee engagement, improvement efforts are less likely to be successful and sustainable.

- Not Fostering a Culture of Continuous Improvement and Lean Management: Without a supportive culture, continuous improvement initiatives may struggle to gain traction and deliver results.

By following these best practices and avoiding common mistakes, organizations can effectively implement SQCDP boards and achieve sustained improvements in operational performance.

Tervene: Your partner for operational performance

Thanks to technology, such as digital SQCDP boards offer vastly more potential than old manual methods by providing a digital interface to improve visibility and accountability in tracking key performance indicators.

For a start, most are cloud-hosted and accessible on mobile devices. This, in turn, helps with informed decision-making.

Once you have the proper infrastructure, you can establish consistent processes and standardized operating procedures throughout the organization. The result is a fully connected environment where everyone—whether working on the shop floor or the back office—can access the data-driven insight they need to become more agile and responsive. That means a more engaged workforce and, ultimately, superior value to your customers.

Tervene is a highly configurable software solution with custom-built SQCDP boards. Our specialists and implementation team are your dependable partners in achieving operational excellence for years to come.

Gain visibility with Tervene’s visual management system

Explore Tervene’s visual management tools

FAQ: SQCDP

SQCDP stands for Safety, Quality, Cost, Delivery, and People. It’s a comprehensive framework and visual management tool that helps organizations monitor and improve key performance indicators in these five crucial areas.

The five pillars—Safety, Quality, Cost, Delivery, and People—represent the interconnected aspects vital for sustainable success. Prioritizing safety prevents accidents and boosts productivity. Maintaining high quality ensures customer satisfaction. Managing costs efficiently leads to profitability. Timely delivery meets customer demand. And valuing and developing your people fosters a motivated and productive workforce.

An SQCDP board visually represents your organizational goals related to the five pillars. It often uses color-coded indicators to show performance against predefined targets. Many modern SQCDP boards are digitized and connected to various data sources, providing real-time information and fostering collaboration.

Using an SQCDP board can lead to enhanced operational performance, improved cost efficiency, and increased employee engagement. It enables early identification of issues, facilitating timely interventions and data-driven decision-making. The collaborative nature of the board also promotes continuous improvement.

Action lists translate identified issues into concrete solutions. They detail specific corrective actions, assign responsibilities, set deadlines, and outline resource requirements. This allows teams to track progress and adjust strategies as needed.

Technology plays a key role in modernizing SQCDP boards. Cloud-based solutions and mobile accessibility allow for real-time information sharing. Integration with various data sources automates manual monitoring and audits. This creates a connected environment that fosters agility and responsiveness.

Tervene provides a configurable software solution with custom-built SQCDP boards. Their team of specialists offers support and guidance in achieving operational excellence through the effective implementation of SQCDP principles.