Visual Management Boards: Your Tools to Gain Visibility

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | November 20, 2025 |

| Read time: | 10 min |

- Visual management boards are information hubs that visually display key production data, helping to improve communication and identify problems quickly.

- There are various types of boards, including SQCDP, Kanban, Kaizen, and 5S boards, each with a specific focus.

- Digital boards offer advantages like real-time updates, data integration, and accessibility, making them a powerful tool for lean manufacturing success.

What is a Visual Management Board?

Visual Management Boards are centralized information hubs that display colour-coded cards and other visual cues to track key performance indicators (KPIs), project statuses, team goals, and more. They play a key role in lean manufacturing, since they act as a communication tool that helps build bridges connecting people, processes, and technology, and they support a culture of operational excellence.

The simplest Visual Management Boards lack digital functionality, such as integration with key data sources or interaction with workers. They also require manual updates, which often means the information on them ends up being out of date, inconsistent, or exposed to human error.

Digitized solutions, on the other hand, offer seamless integrability with data from both the shop floor and back-office by way of automatic updates, all while being readily accessible on display boards and personal devices. This enables more proactive management, since teams can rely on a living scorecard that keeps everyone aligned in real time.

Here’s an overview of the various types and examples of visual management boards and how they enhance your operations:

7 types of visual management boards for manufacturing (examples and ideas)

SQCDP boards

SQCDP boards track the five key pillars of a successful production environment: Safety, Quality, Cost, Delivery, and People. When they’re integrated with other visual management boards and data systems, they provide real-time visibility into important metrics, such as daily targets, potential issues, and resolutions.

They also support KPIs and are often tied directly to daily huddles, making them a central tool for team communication and problem-solving.

SQCDP boards can also complement Gemba walks, where supervisors conduct workplace inspections to observe employees and ask them about their tasks and any challenges they face.

Kanban boards

Ever since their appearance in Toyota factories across Japan in the early 1940s, Kanban, as a part of Lean methodologies, has been the gold standard in production control boards. These visual tools, which are commonly digitized, use colour-coded cards to show the statuses of specific tasks in a production cycle. Statuses might include ‘backlog’, ‘in progress’, ‘under review’, or ‘done’.

They’re also used to help manage inventory and production flow, aiming to reduce waste and prevent overproduction or underproduction.

Kaizen boards

Kaizen is a Japanese word that’s often translated as ‘continuous improvement’. Kaizen is the philosophy of making ongoing, incremental improvements across all areas of an organization, including manufacturing and management processes.

Kaizen boards often look similar to Kanban boards, and there’s usually some overlap. However, whereas Kanban boards are used to manage workflows and visualize tasks in progress, Kaizen boards focus on continuous improvements in processes and culture.

5S boards

5S is another Japanese systematic methodology for workplace management. The term stands for five principles – Sort, Set in order, Shine, Standardize, and Sustain. Sort is about assessing your equipment and decluttering the workplace.

Set in order is about establishing the optimal way to store your equipment. Shine is about keeping the workplace clean. Standardize means turning the first three into a continuing habit. Finally, sustain means maintaining those habits by adopting them as part of your workplace culture.

By using 5S, companies spend less time looking for tools and more time getting work done.

Industry leaders leverage Tervene to gain visibility

Daily management boards

Daily management boards make it easy to track daily changes in the workplace. Often used to support daily standup meetings in manufacturing and software development, these boards are gaining popularity in many other industries. They are also widely used in daily huddles, where teams quickly align on priorities and address issues.

These boards display key performance indicators (KPIs), including production output, worker attendance rate, and the number of issues flagged. The purpose is to foster closer team collaboration and involvement when setting goals for the day and reviewing the previous day’s performance.

Machine and production monitoring boards

Production monitoring boards capture key data from manufacturing processes to provide visibility into production efficiency and quality. They usually work in conjunction with machine-monitoring systems, which collect and transmit data directly from the shop floor via internet-connected sensors and other systems.

While machine monitoring tends to focus on specific equipment assets and production monitoring focuses on the plant level, both can work together to provide valuable curated information and actionable insights.

Andon boards

In terms of the information they display, andon boards are by far the simplest we’ve featured here. However, they’re still of vital importance on any shop floor. Their purpose is to instantly notify management, maintenance teams, or other relevant parties of any potential issues in a production line.

They typically provide just a line number and a colour-coded message signifying status. These statuses may indicate regular operation, delays, errors, or under-maintenance warnings.

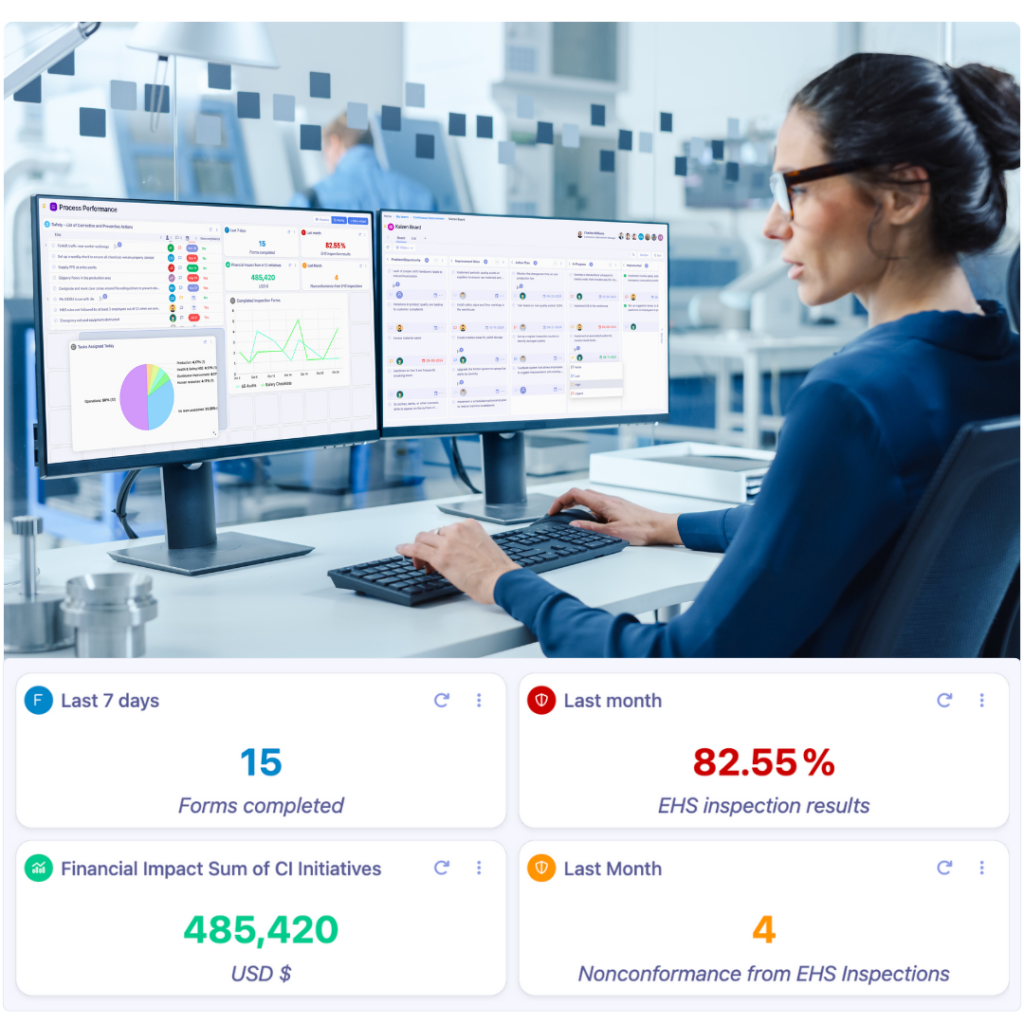

Customizable visual management dashboards on a computer screen.

10 Visual Management Must-Haves [eBook]

How do you choose the right lean board for your needs?

Visual management board ideas & selection criteria

Choosing the right visual management board isn’t about picking the fanciest tool. It’s about finding what works best for you and your team. The “right” board should match your goals, fit into your daily workflows, and feel natural in your industry.

Start with your goals.

Do you want to track tasks, monitor performance, or keep communication flowing? A production floor may need a board showing real-time output. A marketing team might prefer a board that highlights campaign timelines. When you know the outcome you want, it’s easier to select a board that gets you there.

Next, think about your workflows.

Ask yourself:

- Where does work tend to slow down?

- What information do people look for most often?

- Do you need a high-level overview or more detailed tracking?

The answers help you decide between simple task boards, performance dashboards, or process maps.

Your industry matters too. Healthcare teams often use boards to track patients or shifts. Manufacturing relies on boards for safety and production metrics. Creative teams might need boards that encourage brainstorming and collaboration. Aligning with your industry ensures your board solves real problems instead of adding extra work.

Before you set up a board, ask a few practical questions:

| Your goal | Best board type | Why it works |

| Track daily tasks | Task board | Keeps priorities clear and visible |

| Monitor performance | KPI dashboard | Shows results at a glance |

| Spot workflow issues | Process map | Highlights bottlenecks fast |

| Align strategy | Planning board | Connects daily work to big goals |

| Spark ideas | Brainstorm board | Encourages creativity and input |

These questions stop you from creating a board that looks good but goes unused.

And remember: you don’t have to stick to just one. Many organizations mix and match. A daily task board can sit next to a performance dashboard. A strategy board can pair with a workflow map. The mix depends on your needs and how your team works best.

In the end, the right board is the one that keeps your team aligned, reduces confusion, and helps you reach your goals faster. Start small, adjust often, and let your boards grow with you.

Once you’ve picked the right board, the next challenge is using it well. Many teams stumble here, so let’s look at the common mistakes you’ll want to avoid

Track performance and site health metrics with Tervene’s tools

What are the common mistakes to avoid when using visual management systems?

Visual boards can be powerful, but only if you use them the right way. Many teams fall into the same traps.

Knowing these mistakes upfront helps you avoid them.

One common mistake companies face is relying on manual updates. When updates depend on people remembering to make them, boards quickly become outdated. The better approach is to automate updates wherever possible or set clear routines to keep the information fresh.

Another pitfall is overloading boards with too much data. When everything is visible, people struggle to find what truly matters. Instead, keep only the essentials so that the most critical insights stand out at a glance.

Boards also fail when frontline teams are excluded from the process. If the people meant to use them don’t feel involved, they won’t engage. The solution is to involve users from day one, ensuring the board reflects real needs and workflows.

Finally, even the best-designed board can lose relevance if it isn’t updated over time. Circumstances change, and static boards get ignored. Regular reviews and adjustments keep them useful and aligned with current priorities.

Avoiding these mistakes keeps your boards simple, relevant, and truly helpful. Also, consider using the 1/3/10 rule.

What is the 1/3/10 second rule in visual management, and how does it help?

The 1/3/10 rule is a simple way to design visual management boards so anyone can understand them instantly. It’s about how quickly people should be able to “read” the board, depending on their distance from it.

- 1 second: From a few meters away in a work area, someone should grasp the key message at a glance. Big titles, bold numbers, and clear colour signals help as clear visual cues.

- 3 seconds: As they get closer, workers should quickly see more detail, like status indicators, charts, or simple metrics.

- 10 seconds: Up close, they should be able to dive into the specifics, task lists, owners, timelines, or notes.

Think of it as layers of information. The closer you are, the more depth you get.

When you design your board with the 1/3/10 rule, you make it effortless for everyone (leaders, team members, or visitors) to spot what matters fast. That’s how you turn a board into a fundamental management tool, not just wall decoration.

After you’ve sidestepped those pitfalls, the next step is growth. A good board shouldn’t just work today. It should scale as your team and organization expand.

How can the best visual management boards for manufacturing scale with your organization?

Visual boards aren’t just for small teams. They can grow with you as your organization expands. The key is knowing how to scale without losing clarity.

Scaling isn’t about making boards bigger. It’s about making them smarter every day.

That way, your visual management system grows with you, supports collaboration and employee engagement, and keeps everyone aligned on the big picture.

| Stage | What it looks like | Why it helps |

| Team level | One task board for daily work | Builds focus and habits |

| Department level | Multiple boards linked to a dashboard | Creates visibility across teams |

| Enterprise level | Centralized dashboard of key KPIs | Aligns leadership and strategy |

| Cross-functional | Shared dashboards between departments | Improves collaboration and problem-solving |

There are actually two ways to think about scaling. First, from team boards that roll up into bigger dashboards. Second, from one department proving the value before spreading it company-wide.

How do you create a visual management board?

To get the most out of your Visual Management Boards, you’ll need an adaptable, goal-oriented strategy. Here’s a quick run-down of how to get started:

- Review your key metrics, such as production cycle times, quality assurance indicators, and safety metrics, to set the tone for the day.

- Identify and address issues by highlighting any problems or bottlenecks on the board and discussing them with your team.

- Set your daily goals and add them to the board, using colour-coded priorities to keep your team aligned.

- Foster accountability by using performance data visualizations to let team members see how their work impacts overall results.

- Encourage engagement by using digitized boards that make meetings more interactive and allow all team members to participate.

Centralize and customize your dashboards with Tervene's tools and software

Tervene is a fully connected software that enables you to centralize and customize your dashboards. Operational leaders worldwide use our Visual Management tools to empower their front-line teams and executives and improve their productivity in a matter of weeks.

Digitize your dashboards with Tervene and gain better visibility into your operations and KPIs

- Use mobile and digital boards to share performance instantly

- Build custom dashboards to track KPIs, corrective, and preventive actions

- Keep teams aligned with standardized displays and updates

FAQ: Visual management boards

Visual management boards are essentially information hubs that visually display key information about your operations. They use things like color-coded cards and charts to track key performance indicators (KPIs), project progress, team goals, and more. They’re designed to make it easy for everyone to understand what’s happening at a glance.

Lean manufacturing is all about maximizing efficiency and minimizing waste. Visual management boards play a crucial role in this by:

- Improving communication: Everyone can clearly see what’s going on, which reduces misunderstandings and promotes collaboration.

- Identifying problems quickly: Bottlenecks, delays, or quality issues become immediately apparent.

- Tracking progress: See at a glance whether you’re on track to meet your goals.

- Promoting accountability: When everyone can see the status of work, it encourages individuals and teams to take responsibility.

The article mentions several types, each with a specific focus:

- SQCDP boards: Track Safety, Quality, Cost, Delivery, and People – the core pillars of successful production.

- Kanban boards: Visualize workflow and the status of tasks (e.g., “to do,” “in progress,” “done”).

- Kaizen boards: Focus on continuous improvement efforts and process optimization.

- 5S boards: Promote workplace organization and standardization (Sort, Set in Order, Shine, Standardize, Sustain).

- Daily management boards: Track daily KPIs and progress towards goals, often used in daily stand-up meetings.

- Machine and production monitoring boards: Provide real-time data on production efficiency and equipment performance.

- Andon boards: Signal production line issues or disruptions for immediate attention.

Digital boards offer several advantages over traditional, non-digital boards:

- Real-time updates: Information is automatically updated, ensuring accuracy.

- Data integration: Connect to various data sources for a comprehensive view of your operations.

- Accessibility: View dashboards on displays, computers, and mobile devices from anywhere.

- Enhanced interactivity: Allow for greater team engagement and collaboration.

The article provides a basic framework:

- Review your key metrics: Determine which KPIs are most important to track.

- Identify and address issues: Use the boards to highlight and discuss problems.

- Set daily goals: Visually track progress towards those goals.

- Foster accountability: Make performance data visible to everyone.

- Encourage engagement: Use interactive digital boards to promote participation.

What is Tervene?

Tervene is a software platform that provides digital visual management tools and other features to help manufacturers improve their productivity and operational efficiency. Learn more and see Tervene in action.