Gemba Walk 2026 Guide: How to Be a Proactive Leader

| Audience: | Manufacturing and Healthcare Executives, Lean Management and Continuous Improvement Professionals, Operational Leaders and Safety Officers |

| Last updated: | November 28, 2025 |

| Read time: | 14 mins |

- Principles: Go to the Source, Process Focused, Engagement, Respect for People, Problem-solving, and Continuous Improvement.

- Types: Traditional (exploratory) vs. Structured (proactive).

- Benefits: Efficiency, Quality, Communication, Safety, Leadership Development, Continuous Improvement.

- Digitalization: Offers several benefits, including the elimination of manual transcription, automated data collection, and streamlined issue resolution.

Organizations, regardless of their size, can significantly benefit from adopting management practices that focus on efficiency, safety, and quality. Among many Lean management practices, the Gemba Walk stands out. This approach involves managers actively stepping into the work environment to develop a firsthand view of daily operations and potential improvement areas.

What is a Gemba Walk?

A Gemba Walk is a management practice where leaders go to the front lines (to the Gemba) to identify improvement opportunities, potential issues, and waste areas. In the process, managers must walk around where work is done, from factory floors and warehouses to healthcare facilities.

Taiichi Ohno, the father of Just-in-time production, developed the concept of Gemba Walks, a fundamental part of the Lean management philosophy. It’s about engaging with team members, seeing the reality of operations firsthand, and identifying improvement areas.

What is the meaning of Gemba?

Gemba (or genba): The word’s literal meaning in Japanese is “the real place.” It emphasizes on-site observation and refers to where value creation happens, and where most issues and waste occur.

What are the 5 Gemba Walk principles?

Go to the source (Gemba)

This principle encourages leaders to leave their desks and experience the work environment firsthand. It’s about witnessing the operations, grasping the challenges teams face on the floor, and shifting focus from paperwork to real-world situations.

Process focused

Here, the emphasis is on examining and understanding the processes in play, not the individuals performing them. This perspective seeks to find ways to improve these processes while focusing on constructive solutions rather than placing blame.

Engagement

Effective Gemba Walks imply open communication and connecting with the workforce. It’s about asking insightful questions (what, why, and how), genuinely listening to feedback, and seeing the issues from the perspective of those dealing with them daily.

Respect for people

Respect for all the people within the company forms the foundation of Gemba Walks. This principle follows the ethos of “Go see, ask why, and show respect.” It’s about valuing employees’ contributions and creating an environment of shared respect.

Problem-solving and continuous improvement

Central to this principle is the drive towards continuous improvement and effective problem-solving right where the issues occur. It encourages a proactive stance in identifying and addressing problems.

Industry leaders leverage Tervene to structure their Gemba Walks

Traditional vs. structured Gemba Walks

Regarding Gemba Walks, there’s a distinct difference between the traditional approach and the more structured method. Let’s explore how each style works and what makes them unique.

Traditional Gemba Walks

Think of these as more exploratory and open-ended. Leaders might pick a particular focus, like a specific process or problem area. They wander the workspace, observe, ask questions, and jot down notes about improvements or waste reduction opportunities.

Picture a scenario where an executive team, including a quality manager and a supervisor, walks the floor and spots an issue. They aim to understand the problem better and brainstorm potential solutions, all while gathering additional insights in real-time from the team on the ground.

It’s like detective work – looking for clues and piecing together the bigger picture.

Structured Gemba Walks

Now, this is where things get more organized and proactive. These walks follow a set schedule and have a clear objective – to identify issues before they escalate.

Imagine team leaders who regularly check their areas of responsibility, not just waiting for problems to surface but actively searching for potential hiccups and opportunities to improve. This method ensures that leaders stay consistently engaged with the day-to-day operations and can address issues promptly.

Gemba Walk vs. MBWA (Management by Wandering Around)

Let’s delve into the nuances between Gemba Walk and Management by Wandering Around (MBWA), two distinct management methods.

MBWA – Management by Wandering Around

This approach is more informal and spontaneous. Imagine a supervisor who casually strolls through the production floor, checking in with teams and ensuring everything runs smoothly, but without a specific checklist or structured validation process.

It’s a way for managers to stay connected with their teams and the ground realities of the workplace beyond the confines of office paperwork. However, unlike a Gemba Walk, MBWA doesn’t usually focus on specific themes or areas.

Gemba Walk

In contrast, a Gemba Walk is more deliberate and focused. Managers engaging in a Gemba Walk have a clear purpose or theme for their observation. They actively seek out areas for improvement, potential issues, or wasteful activities in specific processes or departments.

It’s a structured approach beyond being present on the floor; it’s about engaging with the work environment to drive continuous improvement and problem-solving.

What is the purpose and value of Gemba Walks?

The main purpose of Gemba Walks is to sustain a robust culture of continuous improvement (also known as Kaizen) at the heart of all efforts.

Gemba Walks systematically identify improvement opportunities and transform ideas into actionable improvement plans. Here are the key reasons why numerous companies across all industries incorporate them into their managers’ schedules:

Increased efficiency

Gemba Walks help managers regularly identify bottlenecks and inefficiencies in the production process. By addressing these issues early on before they escalate, manufacturers improve their efficiency and overall equipment effectiveness (OEE), and reduce waste.

To illustrate this benefit, let’s take a hypothetical example. In a cooling system manufacturing plant, a Gemba Walk may reveal that the distance between the parts inventory and the assembly line is causing delays. The plant then reduces unnecessary movement by reorganizing the layout to smooth production flow and reduce cycle time.

Improved quality & training

By identifying and addressing issues proactively, organizations improve product and service quality. Gemba Walks uncover relevant data and information for actionable solutions, while also helping supervisors identify areas where additional training may be necessary.

For example, a Gemba Walk may help identify inconsistencies in patient care procedures in a hospital. Addressing these gaps through staff training and improved scheduling will lead to enhanced patient care and reduced rates of medical errors.

Better communication

Gemba Walks enable better communication across all organizational levels, from managers and executives to line workers. This effort builds mutual trust, improves department collaboration, and leads to better problem-solving and more efficient processes.

For instance, Gemba Walks may bridge the communication rift between technicians and administrative staff in a medical lab. This proactive management practice leads to more coordinated efforts in handling patient samples and improved turnaround times for test results.

Increased safety

By regularly conducting Gemba Walks, supervisors identify potential safety hazards and take proactive steps to mitigate them before they become a significant concern. This recurring activity prevents accidents and injuries in the workplace.

A Gemba Walk in a chemical plant may reveal a potential fire hazard due to improperly stored chemicals. Management can then rectify the storage methods and reduce accident risks.

Leadership development

Participating in Gemba Walks enables leaders to develop a deeper understanding of the daily routine operations, enhance problem-solving skills, and strengthen employee relationships. It also reinforces the importance of servant leadership and the value of leading by example.

During Gemba Walks in a textile factory, the quality control manager may identify inconsistencies in fabric dyeing processes. By immediately addressing these inconsistencies and implementing standardized procedures, the manager initiates a cycle of continuous improvement that leads to consistent product quality and reduced waste.

Continuous improvement

Gemba Walks facilitate a culture of continuous improvement by enabling leaders to identify and address issues promptly, document improvement opportunities, and monitor progress over time.

The administrative team may notice prolonged wait times and patient bottlenecks in the emergency room during Gemba Walks in a large urban hospital. They can respond by streamlining triage processes and improving communication between triage nurses and emergency physicians.

What are the key steps to an effective Gemba Walk?

To successfully carry out a Gemba Walk, it’s imperative to remind ourselves of the 5 core principles that we discussed earlier: go to the source, focus on processes not people, active engagement, respect for people, problem solving and continuous improvement.

With these principles as the foundation, your Gemba Walks will be set up for success.

Next, it’s time to implement effective Gemba Walks into your business with these 9 key steps:

- Define the Purpose: First, define the Gemba Walk’s main goal. This preliminary step will help the supervisor stay focused on a specific topic and notice finer details rather than get distracted by diverse elements.

Is the walk primarily focused on safety, production efficiency, quality issues, or employee engagement? Narrowing it down helps cut through the noise and align the walk with broader business goals, whereas skipping this step often leads to scattered observations and no real action. - Prepare: Review production schedules, safety guidelines, and other relevant information. Prepare a checklist with pertinent questions and checkpoints. Communicate the plan with employees to ensure cooperation.

Preparation may include reviewing recent performance data, gathering the right observation tools, and making sure the walk won’t disrupt operations. Give your teams a quick heads-up that the intent is to observe processes, not to scrutinize individual performance — this helps reduce resistance. - Observe: Managers must walk around the workplace and conduct their inspection with a prepared checklist, Gemba Walk template , or mobile device. Have them assess processes, record firsthand observations, engage with team members, and identify issues, waste, and improvement opportunities.

This is the heart of the Gemba Walk. Stay curious, don’t rush, and keep your eyes on the process. Avoid the temptation to jump into solutions on the spot at this stage — just observe, listen, and take detailed notes. - Engage and Ask Questions: One of the most overlooked aspects of a Gemba Walk is active employee engagement. This step goes beyond passive observation — it’s about showing interest, building trust, and uncovering insights directly from frontline workers.

Ask open-ended questions and give space for honest feedback. Employees often know the root causes of issues but may stay silent unless prompted respectfully. Keep the tone non-judgmental and focused on curiosity, not critique. - Communicate Points of Interest: Prioritize takeaways and escalate them to the appropriate management level or meeting. After the walk, don’t just let your notes collect dust.

Group your observations into separate categories: quick wins, systemic problems, follow-up needs. Decide which issues need to be addressed at the team level vs. escalated cross-functionally. Communication ensures that no insight gets buried. - Collaborate on Solutions: Before diving straight into corrective actions, bring the relevant teams together to discuss what was observed. Often, those closest to the work will have the most practical, realistic ideas for improvement.

Facilitating collaborative problem-solving sessions improves the quality of solutions and reinforces the continuous improvement culture that Gemba Walks aim to create. - Take Action: Address the identified issues. This initiative may include implementing countermeasures, new processes, providing additional training, or changing the production schedule.

But action doesn’t mean overhauling everything at once — focus on 1–2 meaningful changes from each walk, and make sure they’re clearly assigned and time-bound. Document what’s being done, why, and how success will be measured. Without this, Gemba Walks become all talk, no follow-through. - Follow-Up: Ensure adequate and permanent changes. Repeat this process regularly (daily, weekly, monthly, or any custom recurrence). Communicate changes and improvements to employees. Provide feedback and follow-ups.

This is where many Gemba Walks fail — no accountability, no updates, no improvement loop. Instead, build follow-ups into your process — track changes made, measure impact, and communicate wins or adjustments. - Reflect and Standardize: Take time to reflect on what worked, what didn’t, and how future walks can be more effective. Were you too focused on details and missed the big picture? Was the checklist too rigid? Reflection is where continuous improvement applies to the Gemba walk itself.

After a few rounds of refinements, businesses can standardize the most effective Gemba Walk framework and then replicate it across other teams or sites.

How to structure your Gemba Walk checklist

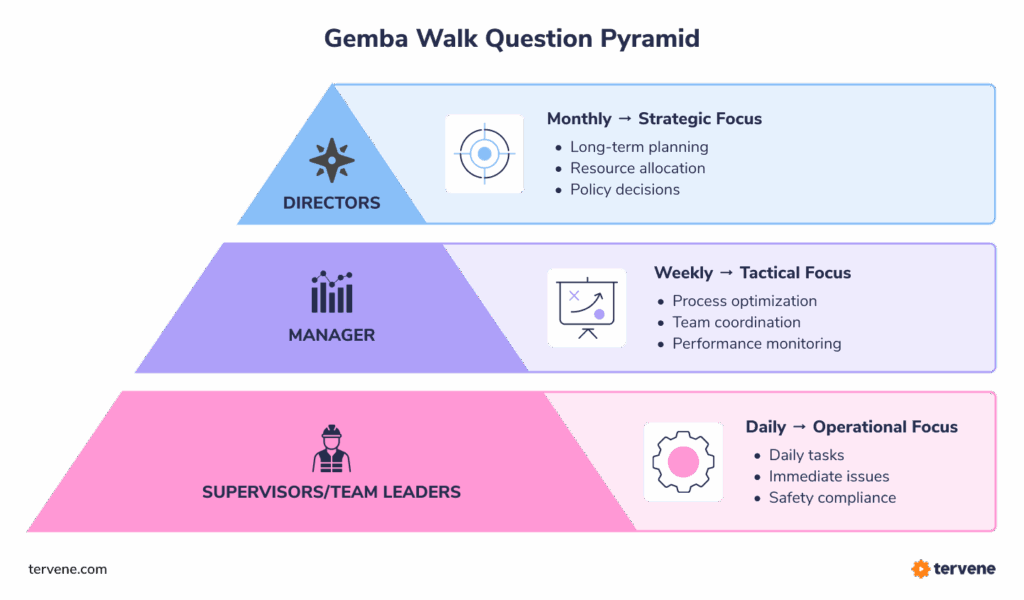

Structuring a Gemba Walk is all about finding the right rhythm for different management levels in your organization. While all levels of management are involved in Gemba Walks, they each have their own unique purposes and timelines.

For instance, team leaders might do their rounds twice daily to closely monitor day-to-day operations. Supervisors could opt for a daily or weekly schedule to balance their broader supervisory duties. As for executives or upper management, a twice-a-month schedule might be ideal to maintain strategic oversight without getting caught up in details.

Whether you lean towards the traditional or structured Gemba Walk framework, here’s a general Gemba walk checklist to keep in mind:

It’s crucial to tailor Gemba Walk questions to the specific roles of the individuals executing them. This alignment with the responsibilities and concerns of each position within the company not only makes the process more effective but also makes each team member feel valued and integral to the process.

Finally, there is no set-in-stone “correct” number of times a company should conduct Gemba Walks — it depends on your unique operations, processes, and even preferences.

Download 12 steps to optimize your Gemba Walks

Gemba Walks: 12 Steps, Checklists & Templates

How Gemba Walks sustain proactive lean management

Proactive management is one of the most essential principles of Gemba Walks. To illustrate it, consider the following example.

A manager is newly in charge of monitoring an automobile parts production line. A superior has informed them that high defect rates have occurred recently. As a first initiative, the supervisor decides to set a daily Gemba Walk in their schedule to identify the root cause of the issue and stay on top of the problem.

During the Gemba Walk, the manager visits the production line, observes the process, and talks with the operators. Together, they notice that one machine produces inconsistent parts and causes defects downstream.

Upon further investigation, the supervisor discovers that the machine needs to be serviced and appropriately calibrated. They schedule maintenance and train the operators to calibrate the machine properly. As a result, the defect rate decreases while the overall efficiency and quality of the production line improve.

By proactively identifying and addressing the issue through a Gemba Walk, the supervisor prevented further defects and improved the production line’s efficiency.

Real-world example: Safran’s success

Safran Cabin Canada showcases how Gemba Walks can propel tangible improvements. They’ve embraced the practice by requiring multiple Gemba Walks daily. The first walk directly informs their daily meetings and calls for immediate action.

Also, frontline managers are tasked with conducting a deeper analysis of at least one issue daily by utilizing tools like Quick Response Action Plans, 5 Whys, or A3 problem-solving. This thoroughness ensures that problems identified during Gemba Walks are actively addressed through structured problem-solving and resolution plans.

Watch this video to see how Safran Cabin Canada (formerly Zodiac Aerospace) leverages Tervene’s full potential.

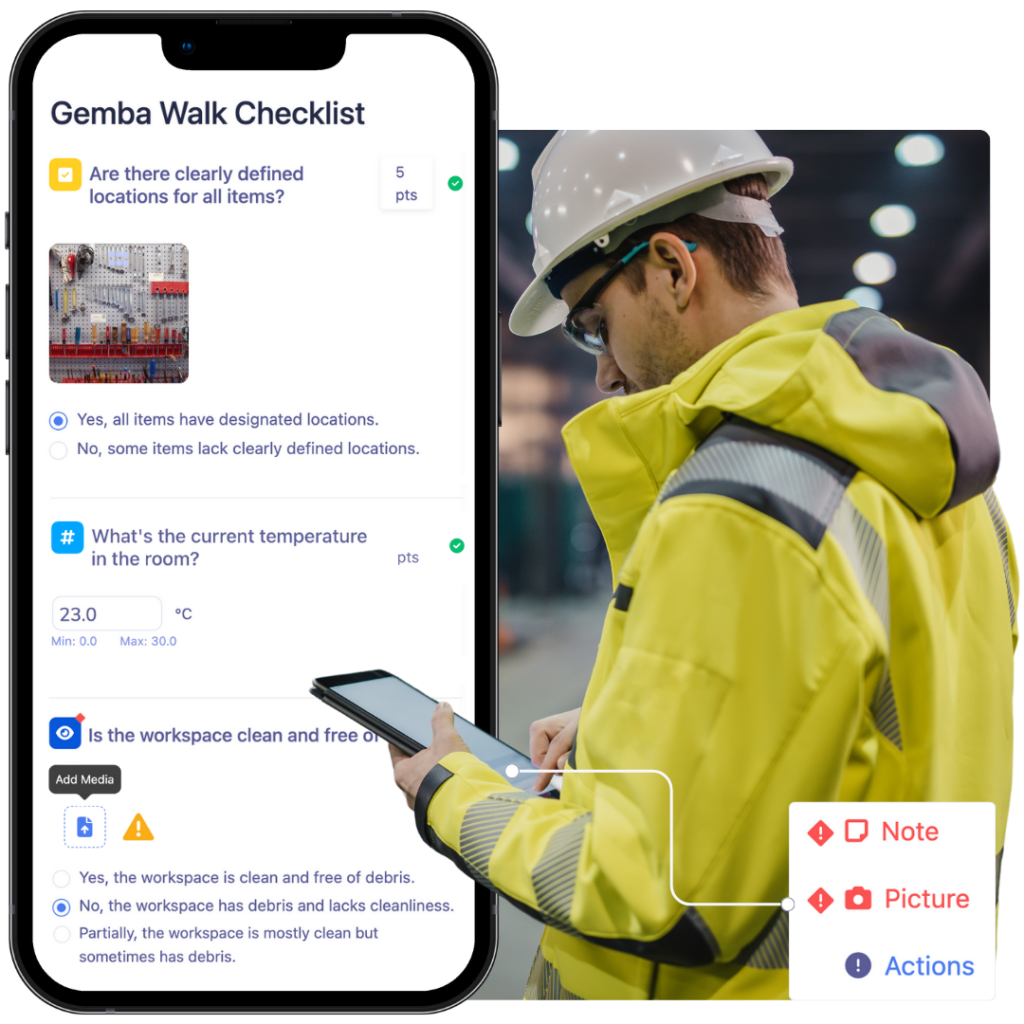

Why digitalize Gemba Walks?

Nowadays, companies can leverage specialized management software to streamline, automate, and digitalize Gemba Walks. There’s also a growing trend of combining in-person and virtual Gemba Walks to increase flexibility, speed, and visibility—without losing the core purpose of going to the source.

Digitalizing Gemba Walks offers several key benefits:

Manual transcription elimination

Traditional Gemba Walks usually require manual note-taking on paper. Someone must transcribe or enter the information into a filing or computer system. This process is time-consuming and prone to errors.

Tervene’s digital solution eliminates the need for multiple entries, as data is entered, sorted, and stored directly into the system. This redundancy elimination saves time and ensures accuracy in the data collected – no need to send emails or transcribe follow-up tasks after a Gemba Walk.

Automated data collection and analytics

Data from digital Gemba Walks is automatically collected and analyzed. This feature enables real-time insights and analysis. Managers and supervisors can make informed decisions quickly and benefit from enhanced visibility.

Streamlined issue resolution

Software solutions allow immediate action after identifying issues during a digital Gemba Walk. Users seamlessly convert an observation into a task or include it in a meeting agenda for discussion. This streamlined resolution ensures that talking points are addressed quickly and are kept from being lost in the day-to-day shuffle of operations.

For example, healthcare administrators can address hygiene issues in patient rooms as soon as they are flagged by staff and avoid ongoing safety problems.

Seamless remote collaboration via video call

Modern platforms support real-time collaboration through video calls, allowing managers and team members to conduct Gemba Walks remotely. This can be especially useful for distributed teams or multi-site organizations that still want to maintain a culture of on-the-floor presence and accountability.

Tracking and logging for continuous improvement

Supervisors can easily log opportunities for improvement in digital Gemba Walk systems. This feature promotes a culture of continuous improvement, as it encourages teams to document Kaizen ideas and track their implementation in a single action.

Standardize Gemba Walks and daily checks with Tervene

Working towards proactive management in manufacturing, distribution, and healthcare sectors requires appropriate practices and tools. Tervene’s Gemba Walk solution facilitates structured and standardized floor tours. The solution upgrades operational control, visibility, and problem prevention. Seamlessly integrating safety, compliance, and quality management, Tervene raises the bar of efficiency and reliability.

Real-life case study: Gemba Walks at Canimex’s factory

Team leaders use their tablets daily to perform Gemba Walks at each workstation. They proactively identify problems and opportunities. Depending on the situation’s priority, tasks with deadlines are assigned to support groups to resolve the issue. Read the complete case study.

Digitize your Gemba Walks and supervisor checklists on mobile

- Create custom forms and checklists, and ensure frontline managers complete them on schedule.

- Turn Gemba walk observations into action, instantly

- Take notes and capture photos on mobile

More Articles From Our Experts

Spot improvement opportunities, anticipate issues, and drive operational excellence with these 6 Gemba Walk App Essential Features.

Here’s the Ultimate Leader LSW Handbook. Drive Lean leadership efficiency and ensure operational excellence at all management tiers.

Uncover how a Daily Management System can elevate operational excellence and boost team efficiency in our comprehensive guide.

FAQ: Gemba Walks

A Gemba Walk Checklist is a tool used to guide managers during their walk around the workplace to ensure they cover essential areas and processes. For more details, check out our Gemba Walk Checklist.

No, a Gemba Walk is not an audit. It focuses on process improvement and employee engagement rather than compliance and inspection. Unlike an audit, which assesses adherence to standards, a Gemba Walk is more about learning and problem-solving.

- Supervisor Gemba Walks: Focus on daily operational aspects.

- Team Leader Gemba Walk: Emphasizes team-level concerns and processes.

- Safety Gemba Walk: Concentrates on identifying and mitigating safety hazards.

- Warehouse Gemba Walk: Tailored for logistics and storage efficiency.

- Proactive Gemba Walk: Aims to anticipate and solve problems before they escalate.

- Do’s: Be respectful, focus on processes, ask open-ended questions, and follow up on findings.

- Don’ts: Avoid blaming individuals, don’t rush, and don’t ignore feedback.

Gemba Walks observe patient care processes in healthcare, identify inefficiencies, and improve patient experience and well-being.

Gemba Walks focus on improving production efficiency, reducing waste, and ensuring quality control in manufacturing.

In a warehouse setting, Gemba Walks help identify logistical inefficiencies, safety issues, and ways to optimize storage and retrieval processes.

Personnel at various levels, including team leaders, supervisors, and executives, should conduct Gemba Walks. Each level focuses on different aspects of the operations.

No. While a Waste Walk targets waste identification and elimination in processes, a Gemba Walk focuses on efficiency, safety, and employee engagement.

Post-Gemba Walk, analyzing findings, prioritizing actions, implementing changes, and communicating these back to the team is crucial. Follow-up is critical to ensure continuous improvement.

A Gemba Walk is a management practice where leaders go to the actual place where work is done to observe processes, engage with employees, and identify improvement opportunities. It’s a key part of Lean and continuous improvement strategies.

While not exclusive to Six Sigma, Gemba Walks are often used in Lean Six Sigma practices to observe processes, identify waste, and support continuous improvement initiatives.