Shop Floor Management (SFM): Adoption, Evolution & Practices

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | October 10, 2025 |

| Read time: | 10 min |

- SFM is built on three pillars: Genjitsu (data-driven decision-making), Gemba (where the work happens), and Genchi Genbutsu (leader engagement with the workforce).

- Key components of SFM include: Lean leadership culture, process confirmation, on-site communication, visual management tools, sustainable problem-solving, performance management, and continuous improvement.

- Implementing SFM involves: establishing clear communication channels, training leaders, utilizing digital tools, visualizing KPIs, and continuously improving processes.

What is Shop Floor Management?

Shop Floor Management (SFM) is a leadership approach rooted in Lean principles that focuses on running daily operations smoothly on the shop floor, improving coordination between teams and leadership, and making sure everyone is aligned.

With SFM in place, production becomes more efficient, processes stay standardized, and teams can tackle issues like waste, safety, and quality with consistency and structure. It also helps create a routine of continuous improvement that’s visible and actionable on the floor.

Evolution and Global Adoption of SFM

Shop Floor Management (SFM) traces its origins back to the first principles of the Lean Production System (LPS), which emerged in Japan during the 1950s as a part of the Toyota Production System (TPS). SFM was designed to help production teams operating at the point of action, also known as “Gemba.”

Created as a framework to manage production processes, SFM rapidly evolved beyond its initial scope. Over time, it has matured into a comprehensive operations approach for improvement across diverse organizational areas (e.g., production, quality, safety, maintenance, etc.).

Importance of SFM Across Industries

Shop Floor Management (SFM) helps streamline operations across industries by creating the structure needed to integrate digital tools and adapt to new technologies. Its core principles make change more manageable and improvement more consistent.

It’s not just for manufacturing either. The same routines are taking hold in logistics, energy, and even healthcare. Wherever people manage complex processes under daily pressure, SFM helps teams cut waste, stay aligned, and respond faster.

Three Pillars of SFM Approach

The foundation of Shop Floor Management (SFM) is built on three Japanese principles that shape how leaders observe, understand, and improve daily operations. These pillars keep decisions grounded in what is actually happening, not just what reports suggest.

- Gemba means “the real place,” where the work happens and value is created. In manufacturing, that is the shop floor, where issues tend to show up first. Leaders who go to the Gemba see problems as they unfold rather than relying on secondhand information.

- Genchi Genbutsu emphasizes the need for leaders to directly engage with frontline teams and processes. Seeing the work up close helps them uncover insights that dashboards alone cannot provide.

- Genjitsu focuses on facts. It encourages decisions based on clear, accurate data instead of assumptions.

Industry leaders leverage Tervene to streamline Shop Floor Management

Core Components of Shop Floor Management

While the three pillars define the mindset, the core components of SFM turn them into daily practices, giving managers the structure to drive consistency on the shop floor.

Lean Leadership Culture

The first component of Shop Floor Management is promoting a Lean Leadership culture. This shift immerses managers directly in production through Genchi Genbutsu, a complete involvement in the work environment.

Hoshin Kanri (another principle of Lean management) also touches upon aligning organizational goals at all levels. Hoshin Kanri is a strategic planning method that unifies continuous improvement and goal achievement efforts. By involving all management levels, SFM promotes and sustains Lean leadership routines.

Process Confirmation and Operational Control

Process confirmation is another necessity in the underlying characteristics of Shop Floor Management. It involves visiting the shop floor (going to the Gemba, where the work is done) to observe operations firsthand, verify critical processes, engage with workers, and check established standards.

This component allows managers to identify issues proactively before they spread into more significant problems. Prioritizing proactive supervision maintains operational efficiency and adherence to standard procedures.

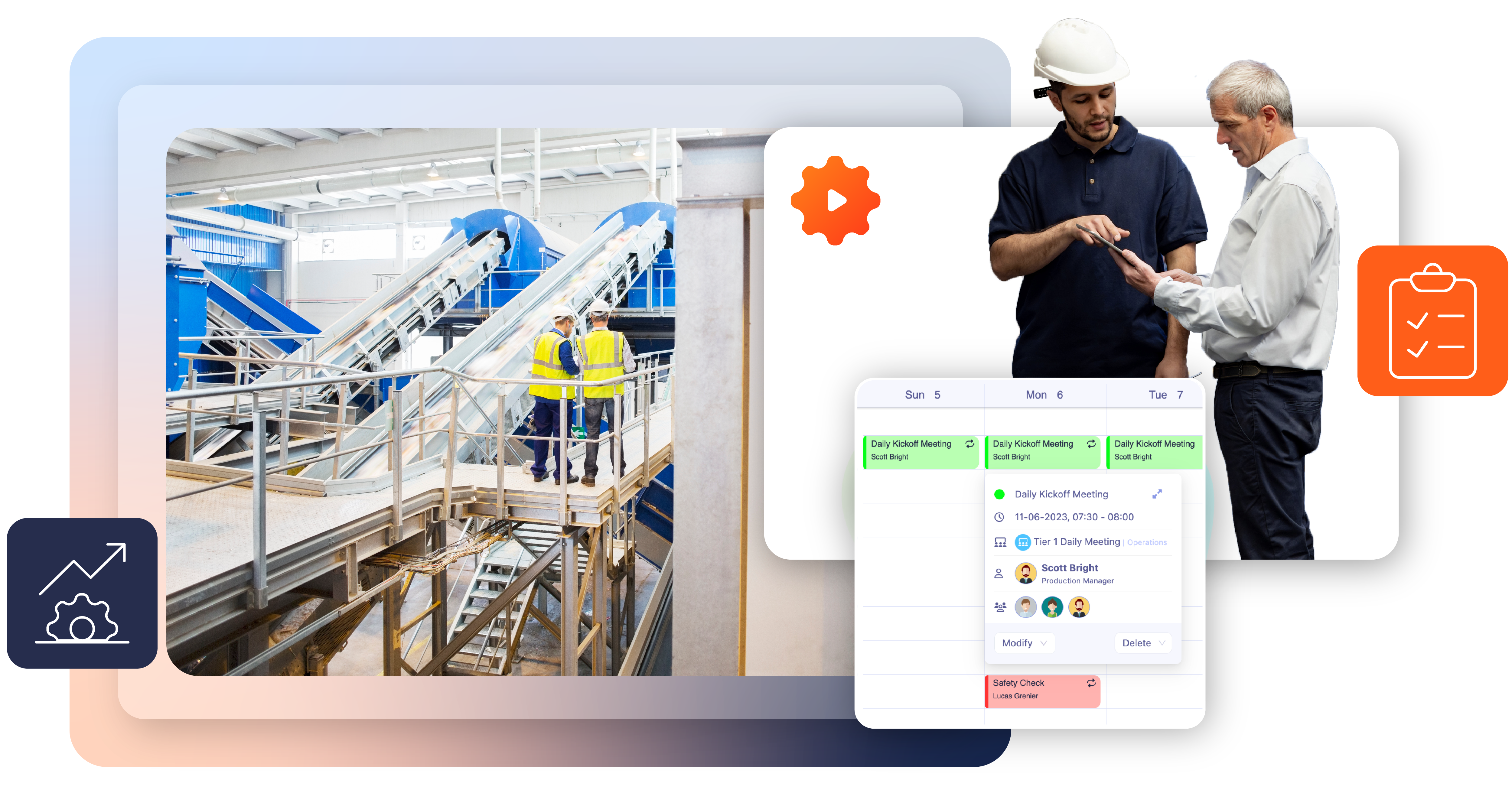

On-Site Communication and Meeting Scheduling

Direct and hands-on communication channels between managers and employees derive from implementing stand-up meetings, daily huddles, and SFM meetings. These meetings involve all management levels and support teams regularly, from daily to weekly to monthly recurrence.

Regular SFM meetings help participants focus on countermeasures and corrective actions in real time. Moreover, encouraging coaching approaches rather than authoritative methods produces an environment conducive to open dialogue.

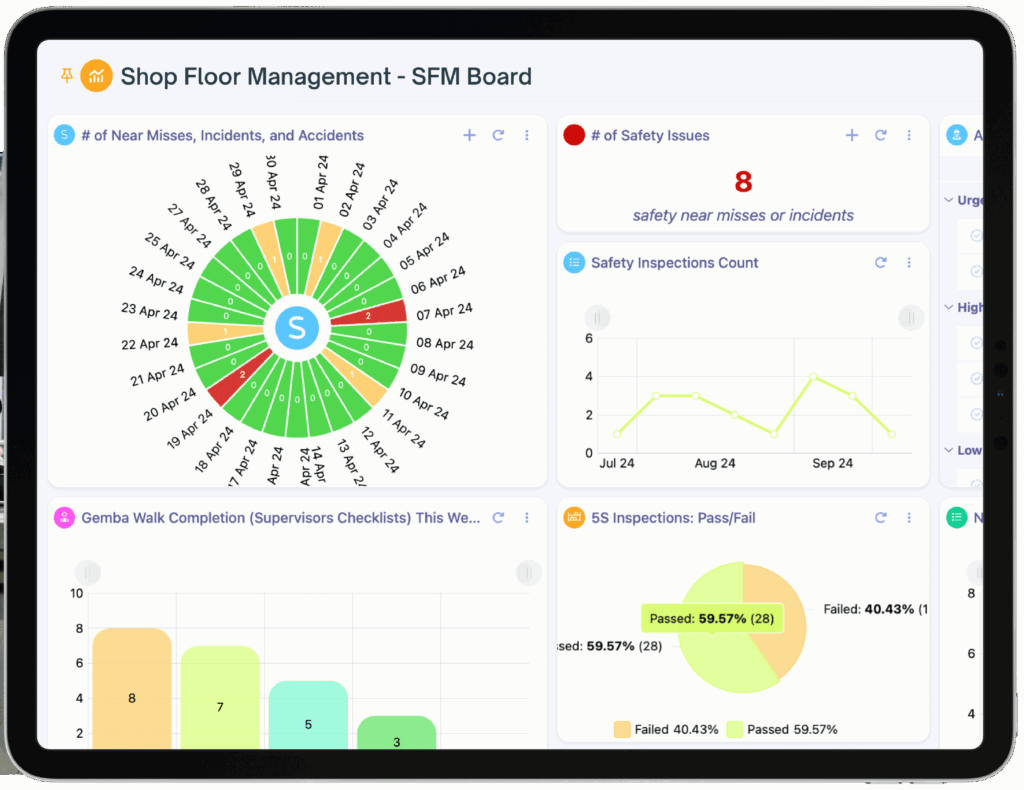

SFM Board and Visual Management Board

Shop Floor Management heavily relies on visual tools like machine monitoring dashboards, SQCDP Boards, Kanban, and PDCA boards to align daily operations with organizational objectives. They facilitate tracking production metrics and aligning day-to-day management.

For instance, within manufacturing, SFM’s utilization of these visual aids enhances operational transparency and accelerates corrective actions. In many plants, these visual boards are now managed through floor management software, which makes metrics easier to track and share across teams.

Sustainable Problem-Solving

Sustainable problem-solving is a long-term element of Shop Floor Management. Encouraging methods suitable for all employee levels is essential to involve everyone in identifying and resolving issues. This approach helps to ensure that problems are not just solved but also prevented from recurring in the future.

Performance Management

Within Shop Floor Management, performance management oversees and measures an organization’s strategy to achieve desired outcomes. For example, in the manufacturing sector, performance management involves monitoring key indicators to validate the efficiency and quality of production processes. Moreover, most manufacturing companies track performance regarding safety, supply, quality, maintenance, delivery, cost, and employees.

Continuous Improvement (Kaizen)

SFM encourages a culture of continuous improvement where workers and managers are empowered to suggest and implement small, incremental changes to improve efficiency, reduce waste, and enhance quality daily.

Standardize and structure management activities with Tervene’s tools

6 Tips for Improving Daily Shop Floor Management

Better shop floor management comes from habits, not hierarchy. When teams know what to focus on and how to respond, improvement becomes part of the routine.

- Cross-functional collaboration Involve support teams such as maintenance, quality, safety, continuous improvement, and engineering in daily routines. When these teams are aligned, issues get solved at the source instead of bouncing between departments.

- Leader Standard Work (LSW) Standardize leadership routines with Leader Standard Work to bring structure and consistency to daily management on the floor.

- 5S System Boost efficiency, safety, and organization with the 5S methodology. It removes friction, reduces search time, and creates the conditions for better quality by keeping the workplace clean and structured.

- Gemba Walks Use Gemba Walk checklists to stay connected to frontline reality. The goal isn’t to supervise but to engage teams, confirm standards, and spot issues early.

- Continuous Improvement Encourage Kaizen by tracking ideas on a Kanban board. Small improvements, done consistently, lead to significant progress when everyone contributes.

- Communication Establish a clear escalation path across all levels of management to make sure issues get resolved quickly and don’t get stuck or ignored.

Benefits of SFM

Improved Collaboration and Leadership

Shop Floor Management has many benefits, and they show up both in how leaders run the floor and how teams actually get the work done:

- It enhances leadership initiatives and facilitates decision-making by centralizing information, rather than forcing managers to work off scattered notes or chase updates.

- It reduces friction, errors, and waste by ensuring smooth production cycles. Standards become clear, handoffs are tighter, and there’s less stop-start chaos that kills efficiency.

- Improved data management also fits into SFM by identifying shop floor areas needing attention. When the data is visible, issues get fixed before they become bigger problems.

- It builds collaboration by pulling operators, supervisors, and support teams into the same rhythm, creating alignment and slowly shaping a stronger shop floor culture.

These factors contribute to time savings, swift reactions, and even reinforced workplace safety.

To make those gains stick, many manufacturers rely on digital tools to keep feedback flowing and routines consistent. As one client put it:

5 Steps for Successful SFM Implementation

Implementing SFM works best when it’s introduced step by step, starting with the basics and building consistency over time.

1. Structured Communication and Meetings (Management Cascade)

Implementing SFM has to be done in phases. The first is the establishment of clear communication channels across the entire organization. Identifying the correct escalation path for deviations from the get-go is critical. Ask yourself, are issues handled at the proper management level?

2. Leadership Emphasis

The second step in implementing SFM is training team leaders and supervisors; coaching managers is vital. They are the main drivers of adoption and need all the tools related to this approach. Management must integrate procedures into daily and weekly routines, and relevant information must always be available.

3. Digital Tools & Automation

This is a good moment to reconsider how information is tracked and shared. Paper notes and whiteboards can slow things down and create extra work when data needs to be transcribed or passed along. Digital tools help reduce that burden by making information easier to capture, access, and use in real time.

For teams managing daily operations, even small shifts toward structured, digital routines can improve clarity and responsiveness without adding complexity.

4. Visualization and Problem-Solving Tools

Adding digital mechanisms to an organization’s arsenal also allows visual KPI tracking to contextualize data and performance at a glance. Regular reports and dashboards give management and executives all the information they need to keep themselves updated, follow up with task owners, and make strategic decisions.

5. Iterative Process Enhancement

Update SFM processes with an iterative method. After each predetermined period, it’s important to reevaluate and integrate lessons learned with various rounds of analysis and feedback to avoid repeating mistakes and to improve quarter after quarter.

Change Management & Adoption Challenges in SFM

Most manufacturing companies don’t fail at Shop Floor Management because the method itself doesn’t work well ; they fail due to a lack of sufficient preparation. Rolling out SFM changes routines, adds visibility, and shifts accountability, which is why its adoption must be carefully planned and explained to workers across all levels before implementation.

Gaining Workforce Support

Operators and team leaders already have their responsibilities. Asking them to gather for daily huddles, fill out new boards, or follow escalation paths can feel like extra work unless the benefit is clear. Leaders need to explain the value from day one: less firefighting, fewer surprises, faster fixes. When people see SFM as a way to solve their own problems, adoption takes off.

Training Leaders and Supervisors

Training is often the make-or-break factor. SFM requires supervisors to coach rather than just enforce. Without preparation, middle managers slip back into old routines, ignoring boards or treating huddles like simple mandatory checklists. Structured training fixes this by showing managers how to run a short but productive huddle, use visual boards properly, and close the loop on any raised issues.

Communication & Escalation

Nothing undermines SFM faster than problems that never get solved. If workers raise the same issue three times with no response, they’ll naturally start disengaging. Clearly outlining escalation paths is crucial for SFM success, in other words, deciding what gets fixed at the line level, what goes to support teams, and what lands with executives. This clarity keeps the entire framework’s credibility intact and prevents issues from stalling.

Recognizing New Wins

Adoption sticks when people see proof that SFM actually makes a difference. Team leaders should find the time to highlight when a routine prevented downtime or when a daily huddle caught a safety risk early. Recognizing these small wins reinforces the behavior you want and shows workers that their effort is worthwhile.

The bottom line is that implementing SFM is more than creating new boards and KPIs. It affects the workforce culture as a whole. Companies that invest in buy-in, proper training, consistent communication, and recognition will see this adoption last in the long run. Those who skip these steps may simply end up with abandoned routines and disengaged teams.

Streamline Your Shop Floor Management with Tervene

Tervene provides digital tools built specifically for Shop Floor Management (SFM). The platform is used by hundreds of mid-sized manufacturers and global enterprises to streamline information flow, structure communication, and support collaboration across teams.

It digitalizes key daily management activities such as Gemba Walks, audits, huddles, problem-solving, tiered meetings, management boards, and project tracking. Remote visibility features also allow managers to monitor operations across multiple sites.

Digitalize your SFM with the right tools

- Gain visibility on frontline operations and performance metrics

- Standardize management practices on the shop floor

- Structure problem-solving and accelerate issue resolution

FAQ on Shop Floor Management (SFM)

Shop Floor Management (SFM) is a lean management approach used to streamline operations, improve collaboration, and optimize processes in manufacturing environments.

SFM incorporates several key components, including:

• Lean leadership culture

• Process confirmation and operational control

• On-site communication and meetings

• Visual management tools (e.g., SFM boards, Kanban)

• Sustainable problem-solving

• Performance management

• Continuous improvement (Kaizen)

SFM offers numerous benefits, such as:

• Improved collaboration and leadership

• Reduced waste and errors

• Enhanced efficiency and productivity

• Increased workplace safety

• Streamlined processes

Implementing SFM involves five key steps:

• Establish clear communication channels.

• Train and coach team leaders and supervisors.

• Utilize digital tools to streamline processes.

• Visualize KPIs and performance data.

• Continuously improve processes based on feedback and analysis.

SFM is built on three pillars:

• Genjitsu: Data-driven decision-making.

• Gemba: The actual workplace where value is created.

• Genchi Genbutsu: Leader engagement with the workforce at the Gemba.

Implementing SFM involves five key steps:

- Establish clear communication channels.• Train and coach team leaders and supervisors.

- Utilize digital tools to streamline processes.

- Visualize KPIs and performance data.

- Continuously improve processes based on feedback and analysis.

A shop floor manager ensures daily operations run smoothly. Their role blends leadership and control: leading huddles, monitoring KPIs, escalating issues, coaching operators, and aligning shop floor performance with organizational goals.

Shop floor control has three phases: order release, order scheduling, and order progress control. Orders are released to the floor, scheduled against resources and timelines, and then tracked in real time to resolve delays and ensure on-time delivery.

Improving SFM starts with structure: clear communication routines, leader standard work, visual boards, and escalation paths. Digital tools and cross-functional collaboration accelerate results by making issues visible and ensuring accountability.