How Short Interval Control keeps operations running at peak performance

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | October 23, 2025 |

| Read time: | 10 min |

- Breaks each work shift into short, focused intervals (1–4 hours) to review performance and act fast.

- Empowers teams to make data-driven decisions that cut downtime and boost productivity.

- Turns quick huddles into a continuous improvement loop (review, act, improve, repeat).

No business can run smoothly all day, every day. Specific issues are bound to come up at some point. In most cases, the sooner you act on them, the more damage you can control.

Yet many companies address these bottlenecks through daily or weekly meetings, which can sometimes result in delays of hours or even days in finding solutions. But what if businesses could address issues in real time as they arise?

This is where Short Interval Control (SIC) comes into play.

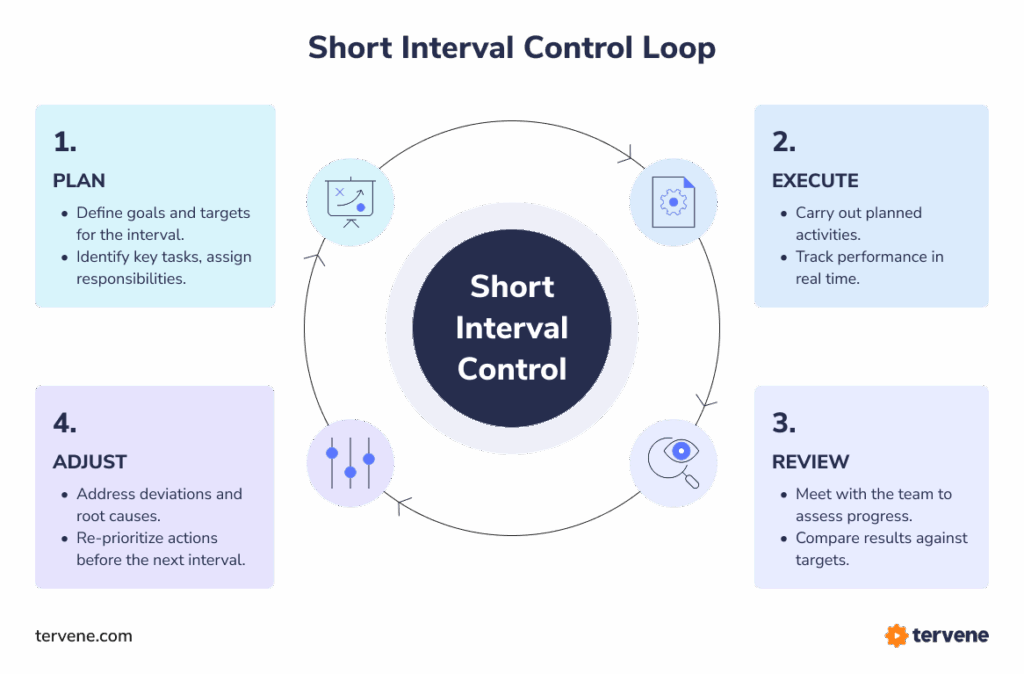

SIC is a simple yet powerful framework that breaks the workday into smaller chunks, typically 1–4-hour intervals. At the end of each one, teams pause operations for a short huddle, explore the data, discuss what’s going wrong (or right), and make immediate course corrections.

The result? Faster, proactive fixes, less financial waste, and smoother-running operations at all times.

Let’s explore how SIC works in real life, its benefits, and how your team can implement this framework right away.

What does SIC stand for in industry?

In various industries, “SIC” stands for Short Interval Control. This term refers to a performance management approach that involves monitoring and managing production or operations in short time increments. Depending on the company, some also refer to it as Short Interval Management, which ultimately describes the same productivity framework.

The main idea behind SIC is to continuously evaluate progress and identify issues early, enabling managers and supervisors to make quick on-the-fly adjustments and prevent problems from snowballing over time.

Quick disclaimer. “SIC” is also the abbreviation for Standard Industrial Classification, which is used primarily for industry codes in the US, but it is entirely unrelated.

[SIC] meaning in an operational context

In practice, Short Interval Control is about proactively addressing operational bottlenecks rather than reacting to them. Instead of waiting for end-of-day or weekly reports, teams check in every couple of hours to sync up and ensure everyone is on track.

If something’s off, they work to find a solution right away. Depending on the industry, this could range from fixing a specific process issue to shifting priorities to real-time strategy adjustments.

Don’t think of them as constant, long meetings. They’re fast, focused team huddles that keep everyone on track and ensure all the different manufacturing elements (machinery, people, materials, and processes) are running exactly as they should.

The beauty of SIC is that it makes every team member and manager an active participant in operational improvement every day. It also builds team intelligence, promotes collaboration, and helps team leads become data-driven problem-solvers.

What is SIC in manufacturing?

SIC was initially created explicitly for factory and manufacturing divisions, where even the slightest issue could derail the entire production process. To this day, SIC remains the most prevalent in these environments despite rapidly expanding into other business operations, from construction and agriculture to tech and beyond.

As a simple example, imagine discovering at the end of the day shift that one of the machines had a glitch in the morning, affecting manufacturing for the rest of the day. Picture the costs associated with this in a high-scale production environment.

With SIC manufacturing, managers would catch that glitch right away and proactively steer production to continue running smoothly.

You’ll often see SIC implemented in environments where continuous production and efficiency are key, be it automotive assembly lines, chemical plants, or electronics. Anywhere downtime or scrap gets expensive quickly.

Industry leaders leverage Tervene to structure their meetings

What is the manufacturing process of SIC?

We’ll explore the SIC process in more detail shortly, but while on the topic of SIC manufacturing, here’s what a typical SIC cycle looks like in factory environments:

- Each shift is broken into small, clearly defined intervals, usually every 1-4 hours.

- During each interval, there’s a scheduled short team huddle to discuss output, downtime, or any other critical metrics in real time.

- If something is off, the issue is discussed right away to identify the root cause. What’s slowing you down and why, what’s harming efficiency, etc?

- Fixes are discussed, assigned, and acted on swiftly.

- Rinse and repeat at each scheduled interval.

It’s a simple yet structured loop: review → act → improve → repeat. You’re not waiting until the next day or the next manager meeting to fix a problem. You get it done right away.

This level of responsiveness is precisely what gives SIC its edge, transforming manufacturing divisions into a real-time performance machine.

Benefits of short interval control

Before diving into the SIC implementation process, let’s take a quick look at the principal value this operational framework brings to the table:

Rapid problem-solving:

All kinds of issues and bottlenecks are identified at an early stage, enabling proactive, immediate responses and reducing unplanned downtime and inefficiency.

Improved productivity:

Frequent check-ins help boost productivity metrics at the individual and team levels while keeping operations constantly running at peak performance, which, in turn, raises the average performance level over time.

Data-driven decisions:

SIC is built on accurate data. No guessing games. Purely analyzing real-time metrics on throughput, quality, efficiency, and delays to make informed decisions and build operational intelligence across the whole team.

Stronger team engagement:

SIC introduces a structured routine of team communication that gives everyone a voice. This not only empowers team members and boosts team morale but also creates a culture of transparency on performance.

Continuous improvement:

With SIC, businesses create an environment that promotes continuous improvement. It becomes a part of everybody’s job, rather than something purely driven by managers.

How to implement short interval control

Knowing the theory of SIC is one thing. Integrating it into a real-life business environment with existing processes and moving elements, that’s another.

So how do you actually implement Short Interval Control, whether in a manufacturing division or another fast-paced work environment?

The good news is that SIC implementation doesn’t have to be overly complicated, especially with dedicated tools like Tervene.

Dave Forgues, Production Director at Manac Inc., shared that “through my role as director, [Tervene] helps me structure short and efficient daily meetings with the different sectors of production services.”

That said, SIC implementation certainly requires planning, training, and commitment from all team members involved.

Here are the five key steps to introduce SIC into your operations:

1. Start with shift intervals that match your workflow

Pick an interval schedule that best matches your production or operational rhythm. For most organizations, a good starting point is a single midday huddle (for the typical 8-hour shift). With time, as everyone gets more used to these huddles and, most importantly, teams start seeing tangible improvements, it’s time to move to more frequent daily intervals.

The main objective here is to find the balance between meeting frequently enough to catch problems without being so frequent that you create meeting fatigue or productivity dips.

Whichever structure you decide on, it’s generally advisable to keep it consistent (exact times every day) and anchor it to existing breaks or shift changes (like in factory environments). Consistency beats perfection early on.

Finally, it’s the manager’s or team leader’s responsibility to ensure that all relevant data and questions are fully ready the moment the interval buzzer goes off.

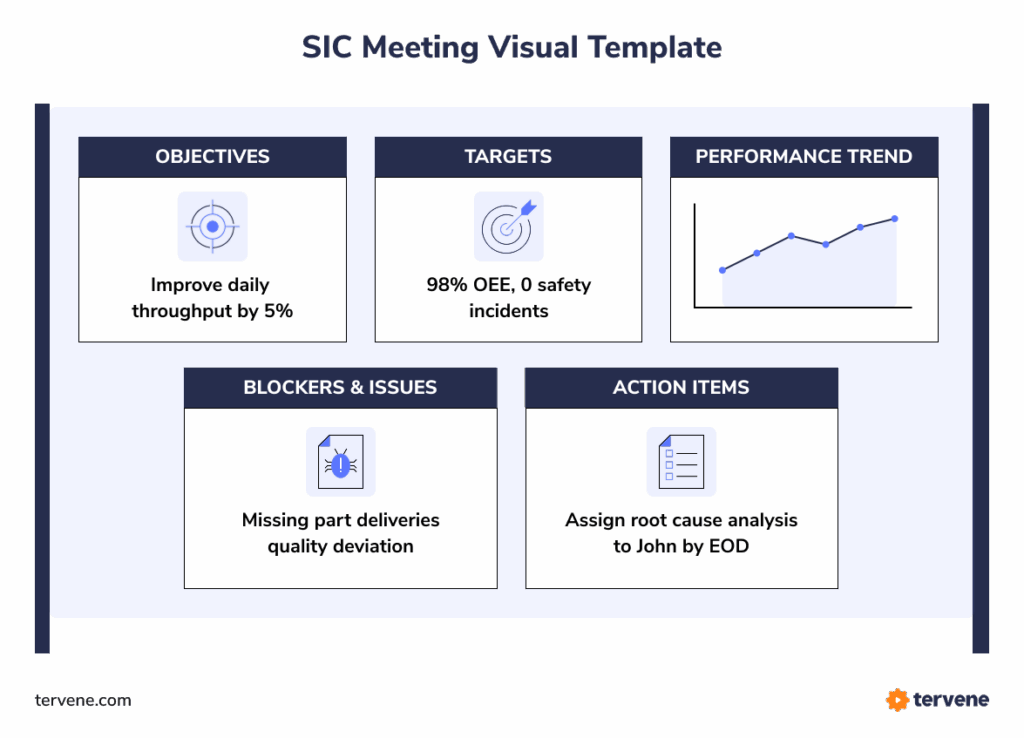

2. Standardize the SIC meeting. No fluff allowed

Ideally, keep each huddle to 10 minutes or less. Follow a fixed, easy-to-follow script that covers the areas most important to your unique operations, for instance, comparing real-time results with target results and discussing any discrepancies.

Once discussed, assign fast, achievable actions to the appropriate people, confirm accountability, and that’s that. The main goal here is rhythm and efficiency, not deep-dive discussions or brainstorming sessions (leave those for meetings).

If an issue needs more than 5–10 minutes to solve? Flag it and escalate, don’t derail the huddle.

3. Train & assign roles before you launch

Before the first huddle, brief everyone on why SIC exists and what they can expect. This way, you get fewer surprises, faster fixes, and less firefighting in the long run.

Introduce the structure of these team huddles so all team members know they have the freedom to speak up, the responsibility to track performance, and the responsibility to keep everyone on the same page regarding what should be discussed or brought to attention.

Managers will also need some practice to ensure these huddles run smoothly and swiftly, following a clear structure and chain of command. For instance, assigning huddle leads, maintenance and quality control roles, etc.

Accountability is everything, especially in the early stages of setting the pace. Make it clear who’s tracking actions, who’s following up, and what success looks like.

4. Visualize the data when possible

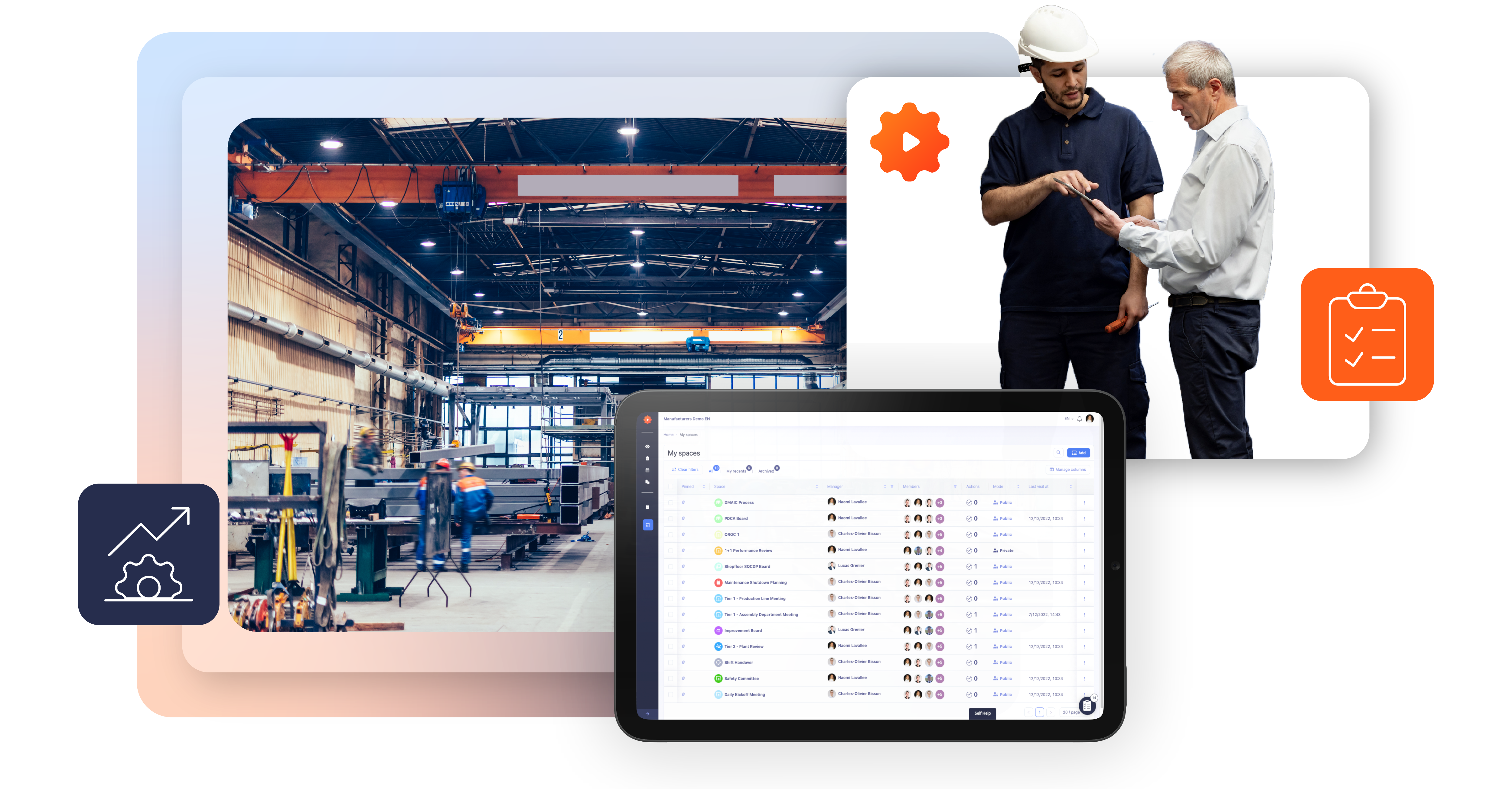

All data has to be in the line of sight of all team members. Ideally, you would use specialized software like Tervene to run SIC meetings, but even a simple whiteboard with hourly/daily targets and colour-coded outputs works just as well.

Of course, going digital aligns with modern operational work environments across all industries, but the primary concern here is visibility and accessibility for the entire team.

All data should be updated in real time, not at the end of the workday (which goes against the whole purpose of SIC), and ideally be easy to interpret at a glance, so that it keeps everyone aligned and accountable without taking away from the actual work.

5. Track actions and close the loop every time

Once all issues, metrics, and suggestions are discussed, every huddle must end with a short action list. What, who, by when. Write it down where everyone can see it, and when it’s time for the next huddle, you can start by ticking off what got done and what didn’t.

If a particular issue rolls over more than twice, escalate it. That’s a signal that the fix is bigger than anticipated and requires longer meetings or discussions, which SIC intervals don’t accommodate.

This closed-loop habit turns SIC from “just another meeting” into an efficient improvement engine, shows people that their input matters, and builds trust and accountability.

Final thoughts on Short Interval Control

Short Interval Control has proven to be a highly effective productivity framework, especially in fast-paced work environments where minor issues can spiral into costly roadblocks.

SIC creates a culture of proactive, rather than reactive solutions, and gives teams the speed and structure to ensure systems and processes run smoothly at all times.

While these shift intervals may seem like “extra meetings” that take time away from actual work, they are, in fact, short, efficient, and ultimately save time and resources in the long run by eliminating bottlenecks early.

So if your company still waits until the end of the workday or workweek to discuss what went wrong and how to fix it, perhaps it’s time to break the cycle and incorporate SIC into your operations.

And if you want a frictionless SIC implementation from day one, Tervene gives frontline teams the tools they need to run structured huddles, assign actions, streamline collaboration, and drive accountability. All in one place.

Start with one interval. Run one huddle. See what happens. Odds are, you’ll never go back.

SIC software

FAQ About Short Interval Control (SIC)

Short Interval Control, or SIC, is a performance management approach that divides the workday into smaller time intervals—typically 1 to 4 hours. At the end of each interval, teams hold a quick huddle to review real-time data, discuss performance, and address any issues immediately.

In manufacturing, SIC helps teams catch and resolve process issues before they escalate. Each shift is split into short intervals with scheduled check-ins. During these huddles, teams review production metrics, identify problems, assign corrective actions, and track results in real time.

SIC offers several advantages:

-

Faster problem-solving and reduced downtime

-

Improved productivity and efficiency

-

Real-time, data-driven decision-making

-

Higher employee engagement and accountability

-

A culture of continuous improvement

No—while SIC originated in manufacturing, it’s now used across industries like construction, logistics, and even software development. Any fast-paced environment that benefits from quick adjustments can apply SIC principles.

SIC huddles are designed to be short and focused—usually 5 to 10 minutes. The goal is to quickly review performance, address immediate issues, and assign clear next steps without disrupting workflow.

Unlike daily or weekly meetings that review past performance, SIC focuses on real-time monitoring and proactive problem-solving. This means teams can make immediate corrections rather than waiting until the end of the day or week.

To begin, define your intervals (e.g., every 2 hours), standardize a simple meeting agenda, train your team, and set up visual tools (like whiteboards or digital dashboards) to track progress. Consistency and clear accountability are key to success.

In an industrial context, SIC stands for Short Interval Control. Be aware that SIC can also mean Standard Industrial Classification, but they are completely different concepts.