Digital Transformation in Manufacturing: The 2026 Industry Guide

| Audience: | Manufacturing Managers, Healthcare Administrators, Operational Excellence and Lean Management Practitioners, HR Coordinators, Organizational Leaders |

| Last updated: | October 28, 2025 |

| Read time: | 12 min |

- What digital transformation really means: how true digital transformation differs from simple digitalization, and the four key dimensions all leaders must address.

- The measurable benefits: how transformation boosts agility, quality, cost efficiency, and compliance, and why delaying puts organizations at risk of falling behind.

- How to make it work: a roadmap covering leadership routines, real-time visibility, ERP integration, and connected shop floors.

What Is Digital Transformation in Manufacturing?

Digital transformation in manufacturing is the end-to-end integration of digital technologies across every layer of operations, from daily work on the production line to executive decisions. The core objective is to create a connected, data-driven, and agile organization.

It’s a restructure of how a plant runs, rethinking how work gets done, how leadership decisions are made, and the kind of culture that drives performance forward.

When it works, machines, operators, and software are fully aligned. As a result, data guides every process, agility becomes the default, and companies adapt faster to customer needs and market changes.

True digital transformation is more than simply swapping clipboards for tablets or digitizing tasks in isolation. It requires structured management routines, meaningful KPIs that frontline teams can act on in real time, and a culture where issues are visible and solved before they escalate.

The bottom line is that digital transformation is shifting how manufacturers create value and stay competitive in 2026 and beyond

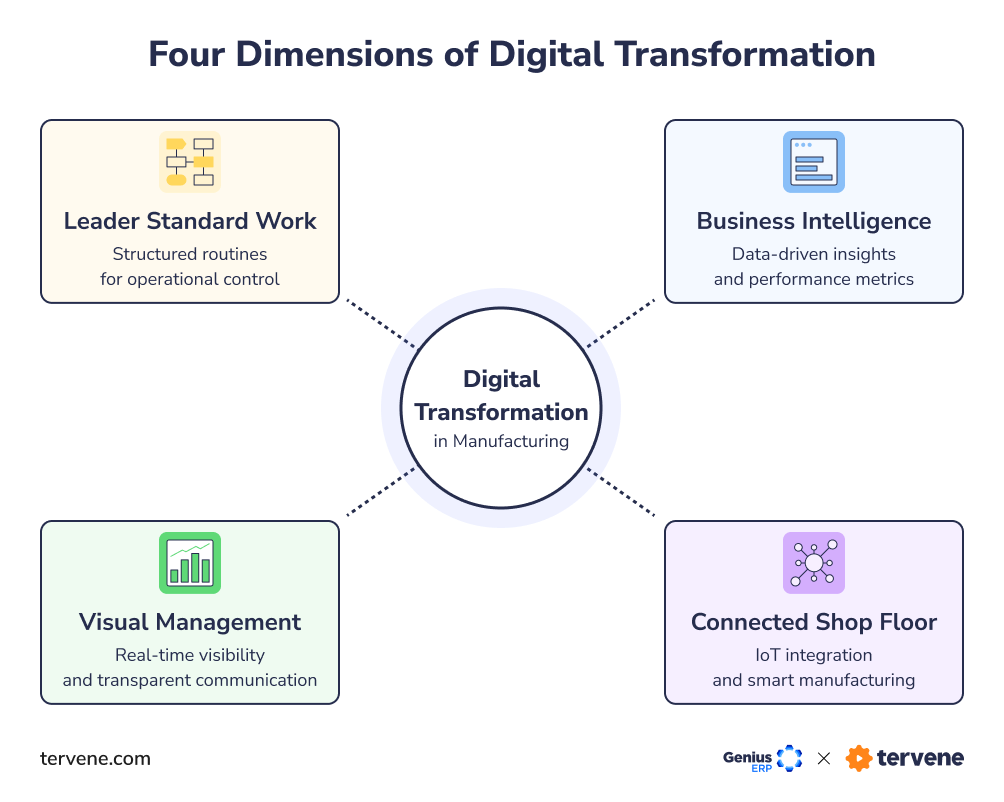

What are the four types of Digital Transformation?

Experts usually break down the digital transformation strategy in manufacturing into four key categories:

- Process transformation: using Daily Management Systems, IoT, or ERP tools to cut all operational waste and smooth out workflows.

- Business model transformation: shifting how value is delivered, like moving from pure product sales to service-driven models.

- Domain transformation: branching into new markets or offerings made possible by digital tech, such as predictive maintenance or digital twins.

- Cultural transformation: the hardest but arguably the most important, changing how people think and work. A data-driven, collaborative culture that sticks.

Manufacturers often entirely focus on process automation and forget the rest. But without culture and leadership to sustain it, the impact eventually fizzles out. True transformation happens when all four elements move forward together.

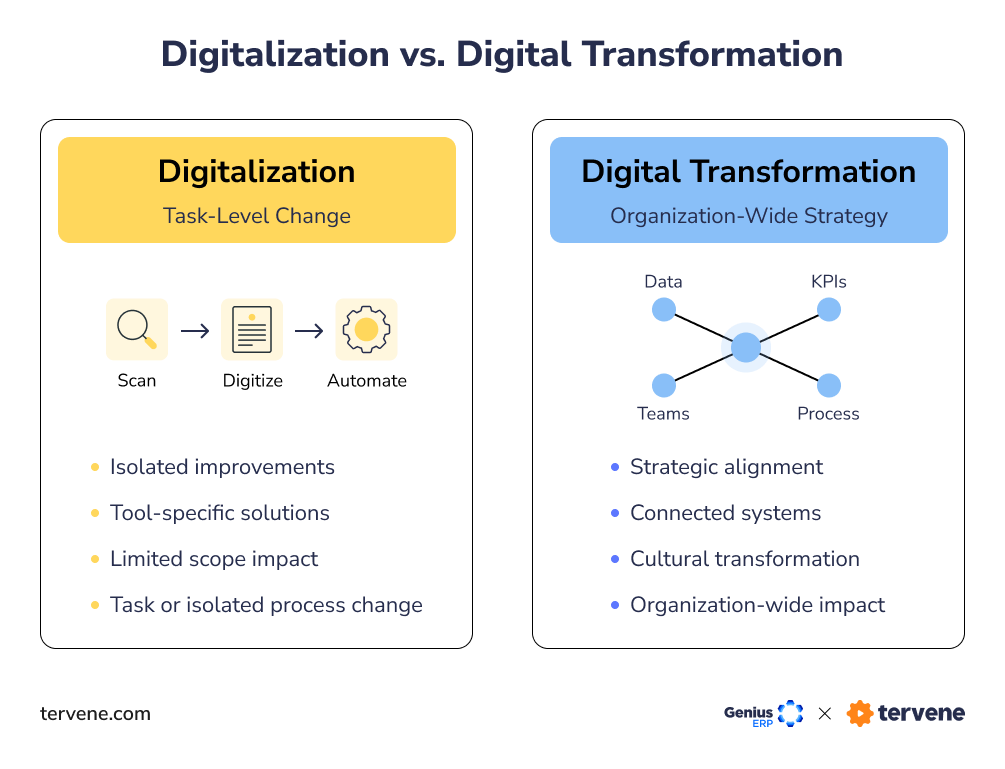

Digitalization Manufacturing vs. Digital Transformation

These two terms are often used interchangeably, but they don’t mean the same thing.

Digitalization is the act of taking analog manufacturing processes and making them digital. Think moving from paper travelers to tablets, logging downtime in an app instead of a notebook, or replacing Excel reports with an ERP dashboard. Useful? Very much so, but still tactical.

Example case study: At Siemens’ Haguenau plant, digitizing daily management routines replaced paper forms and emails with real-time audits and Gemba walks. The shift led to 17,000+ digital walks, 330 audits, and a 96% resolution rate on issues, a clear efficiency win.

Digital transformation, on the other hand, is strategic. It’s about changing the way the factory runs as a whole. Instead of digitizing each task in isolation, companies rebuild manufacturing processes, leadership routines, and decision-making around real-time data. That’s where the big step-change in performance comes from.

One simple way to think about it: digitalization is the toolbox, whereas transformation is the house you build with it. Both are necessary, but it’s important not to confuse the quick wins of digitalization with the structural overhaul of transformation.

Top manufacturers use Tervene to digitalize management and drive performance

Benefits of Digital Transformation in Industry 4.0

Industry 4.0 is no longer a futuristic vision, it’s become the baseline of leading organizations across all industries. Manufacturing companies that transformed with digital programs are now pulling ahead, whereas the ones still running on paper and disconnected systems are falling behind.

Here are the main value points that a digital transformation strategy brings to the factory floor:

- Greater agility: Connected operations can shift schedules, resources, and workflows on the fly. That means reacting fast to supply hiccups, demand spikes, or quality issues that show up mid-run.

- Better quality and reliability: Standard routines tied to live KPIs cut down on errors and raise first-pass yield. The output is consistent efficiency, with less guesswork.

- Higher productivity and lower costs: When data flows automatically, less time is lost to chasing numbers or rework. Downtime drops, wasted motion disappears, and managers spend more time improving instead of putting out fires.

- Compliance and traceability: Regulations are tightening, and sustainability is more important than ever. Digital systems give teams the clean trail their customers and auditors expect.

AI (Artificial Intelligence) and IoT (Internet of Things) adoption is accelerating and transforming how businesses operate, but they can only work if the underlying data is digitalized in the first place. Manufacturers who delay this will find themselves too slow, too opaque, and too expensive compared to those already running connected, digital-first operations.

Your 2026 Digital Transformation Roadmap and Template

To put theory into practice, here’s a brief step-by-step roadmap to effectively implementing digital transformation in modern manufacturing operations.

Step 1: Anchor transformation in prioritized business processes

A lot of digital projects fail because nobody stops to ask the most basic questions: what are we actually trying to fix? What are our biggest challenges? For most manufacturing plants, the core issues are pretty familiar: lead times slipping, defect rates too high, output that jumps around whenever labor or supply pressure hits.

This is the right place to start. Pick three to five KPIs that tie directly to those outcomes, such as on-time delivery, first-pass yield, and equipment uptime. These will act as the north star of your transformation. Skipping this will result in disconnected pilots that look promising on paper but don’t move the needle in the real world.

Step 2: Establish Leader Standard Work and Daily Routines

ERP systems bring powerful capabilities to unify data, streamline workflows, and keep operations connected across departments. And with the right leadership routines in place, that power translates directly into daily performance gains on the shop floor.

Leader Standard Work (LSW) gives every manager that clear, consistent playbook: daily huddles, Gemba walks, tiered meetings, and scheduled audits. Same playbook, shift after shift.

LSW practices keep supervisors proactive instead of reactive, ensuring issues are addressed quickly and teams stay aligned on priorities at all times. They also close the gap between what leadership wants and what’s actually happening on the production line.

Platforms designed for structured management routines help make them stick, with actions logged, issues escalated, and completion tracked so everything is streamlined and accessible to all team members. This is the first step to moving beyond firefighting and into continuous improvement.

Want to get up and running as quickly as possible? Download our actionable week-by-week PDF roadmap to implement LSW in 1 month.

Step 3: Build real-time visibility with Visual Management

If teams can’t see performance in real time, they can’t act in real time. Too many plants are still running off whiteboards and end-of-day summaries. By the time the numbers show up, it’s already too late. Visual management changes that, digitizing all boards and making them accessible at a glance.

A digital SQCDP — safety, quality, cost, delivery, people — board or KPI dashboard flags abnormalities instantly and makes it clear who owns the fix. That cuts reaction time, forces accountability, and aligns departments around the same priorities. It’s not about visually appealing dashboards, it’s about turning raw data into signals people can act on right away.

Download our eBook highlighting the 4 pillars and 10 proven best practices of Visual Management, backed by hands-on experience with manufacturing leaders and multi-site organizations.

Step 4: Connect the shop floor through ERP integration

Paper travelers and siloed spreadsheets slow everything down and hide problems until they blow up. A connected shop floor does the opposite. When an ERP connects directly to the production line, operators can digitally log all their work, machines automatically update their own status, and managers see the schedule shift live. This creates a single, unified version of the truth.

Genius ERP is a great example, linking production, planning, finance, and even sales, ensuring that no department is running blind. The payoff is fewer errors, more accurate schedules, and everyone working from the same playbook, delivering on promises made to customers.

Step 5: Strengthen data and analytics for decision-making

Data by itself doesn’t solve anything. The point is to turn it into faster and more precise decisions. That means automating KPI collection and making the results visible daily. The goal is to pair lagging indicators (throughput, scrap, downtime) with leading ones, such as audit scores or open issues.

This combination lets you spot drift before it snowballs. Modern ERP and BI systems take it one step further, using predictive analytics to forecast demand swings or flag process risks. But the key is to not drown in numbers. So, if a metric doesn’t inform a decision or action, it isn’t worth tracking. The focus should be on the data that drives operational improvement.

Step 6: Scale and sustain through culture and training

Digital transformation is a shift in how the entire organization runs. And it doesn’t work if it lives only at the top. Everyone, including frontline operators and shift supervisors, has to be plugged into the same routines and connected data flow.

Leaders need to know how to run structured huddles, whereas frontline teams need to effectively leverage software to make their jobs easier, not harder. This is why training is so critical. It’s also important to celebrate the quick wins early on, for instance, faster problem resolution, so teams stick with it in the long run. Only once the basics hold, then it’s time to layer in the more advanced stuff like AI scheduling or predictive maintenance.

Download Your Free PDF: Digital Transformation Guide

Manufacturing leaders don’t need more theory, they need practical direction and proven expertise. This co-produced playbook by Tervene & Genius ERP delivers both.

Inside, you’ll find real client quotes, fact-checked numbers, and tested practices that show exactly how digital transformation improves manufacturing organizations.

It’s a guide built from real operations, designed to help you move from scattered digital projects to a connected system that drives measurable results.

What Should Be On Manufacturing Leaders’ Radar in 2026

Quick-Win Starting Points for Manufacturers

Most plants don’t need to wait years to see results. There are a couple of moves they can roll out almost right away that show visible returns and help build momentum for bigger change:

- Digitize tiered meetings: Swap the paper agendas for digital checklists. Make sure every shift handover includes the numbers that truly matter (safety, quality, delivery) plus any issues from the last shift. Keep it routine, give people clear accountability, and follow up. Just this shift alone usually brings recurring problems to light that no one noticed before.

- Top five KPIs on visible boards: Don’t drown in metrics. Pick the five that matter most for your plant, be it lead time, uptime, quality, or anything that’s most aligned with your priorities. Put them where everyone can see them, and keep them updated at all times. Once teams see targets slip, adjustments happen faster.

- Live production loading and schedule transparency: Supervisors and operators need to see what’s queued, which machines are down, and the order status as it changes. That kind of visibility keeps work balanced and stops the unexpected surprises at shift changes.

If you want the deeper playbook with more actionable tips and expert proof points from industry leaders, check out the eBook below.

Standardize work and gain clear visibility with Tervene’s tools

Case Study: Schneider Electric’s Lexington Smart Factory

At its 60-year-old Lexington, Kentucky plant, Schneider Electric proved that even legacy facilities can successfully implement digital transformation.

The site combined lean routines with digital tools like Leader Standard Work, digital Gemba walks, IoT energy meters, and predictive analytics.

The results were concrete: ~90% less manual paperwork, reported gains of up to 20% faster repair times, and nearly 6% less unplanned downtime. On the sustainability front, the plant also achieved 26% lower energy consumption and 30% fewer CO₂ emissions, earning recognition from the World Economic Forum.

This is just one of many real-life cases of measurable results from digital transformation. For more success stories and expert insights from leading manufacturing firms across all industries, check out the leadership guide.

Common challenges and pitfalls (and how to dodge them)

There are many challenges in manufacturing that companies face, regardless of industry. When it comes to digital transformation initiatives, most stall for the same predictable reasons:

- Tech-first instead of value-first: Companies chase tools without tying them back to real KPIs. The result? Shiny dashboards that don’t improve performance.

- Siloed pilots: Running isolated experiments in one department without scaling them leaves the rest of the plant untouched.

- No ownership or routines: Without Leader Standard Work and tiered accountability, new systems collapse into firefighting.

- Vanity KPIs: Tracking dozens of numbers that don’t drive decisions wastes time and mismatches priorities.

- Paper/digital hybrids: Mixing whiteboards and spreadsheets with “half-digitized” workflows often creates more confusion than clarity.

The fix to these challenges is simple, but not easy: anchor every initiative in measurable value, enforce standard routines, and give frontline leaders the structure and training to make those new systems stick.

Pair those routines with platforms that digitize leadership practices and connect the shop floor to your ERP, and transformation stops being a theory, it becomes the way the factory runs every day.

Your Next Step in Digital Transformation

Digital transformation is more than a side initiative, it has become the most prominent operating model of the modern manufacturing environment. Companies that embrace it see faster decisions, tighter control, and operations that hold up under pressure. Those that don’t will fall behind.

The good news is that you don’t have to start from scratch. Specialized management tools like Tervene and Genius ERP are designed to support manufacturing workers at every level, from operators to executives, helping them build a fully functional digital system in no time.

For more proof points, case stories, and expert insights, download the full co-branded eBook — and see how leading manufacturers turn digital initiatives into measurable performance gains.

What Should Be On Manufacturing Leaders’ Radar in 2026

FAQ: Digital Transformation in Manufacturing

It’s the shift from disconnected, manual operations to a fully connected, data-driven system. Transformation means decisions flow from real-time data, teams follow structured routines, and every part of the business — from shop floor to boardroom — runs on the same digital playbook.

Most frameworks point to: technology, processes, people, and culture. Transformation succeeds only when all four are aligned. Technology alone isn’t enough without structured routines and empowered teams.

They are: People, Process, Platform, Performance, and Purpose. These elements ensure transformation is not only technical but also strategic and human-centered.

Examples include digitizing tier meetings, using digital performance boards for key KPIs, and integrating ERP with shop-floor reporting. These build quick momentum before scaling to larger initiatives.

It enables them to standardize operations across multiple sites, unify data flows, and cut down inefficiencies at scale. The result is better visibility, more predictable output, and faster adaptation to market volatility.

Digitalization means converting paper-based or manual processes into digital ones (e.g., audits or work orders). Digital transformation goes further. It changes leadership routines, integrates ERP with the shop floor, and builds a data-driven culture across the organization.

Global supply chain volatility, labor pressures, and sustainability regulations are making agility and visibility non-negotiable. Manufacturers that delay risk being left behind by more connected, efficient competitors.