Blog

What's new at Tervene

Despite newly promoted managers’ technical knowledge, they may still need more management training and structure. They might forsake essential managerial activities as they react to unforeseen issues on the production floor. Undoubtedly, mastering hard skills doesn’t necessarily translate into possessing soft skills. Not to mention that senior and newly promoted supervisors will certainly adopt different […]

Key Takeaways (TL;DR): What Is an Operational Excellence Management System (OEMS)? An Operational Excellence Management System (OEMS) is an administration framework for any organization seeking peak efficiency and performance. OEMS embeds a culture of excellence and accountability at every management level. This all-inclusive system drives real change in performance, health, environmental, and safety (EHS) outcomes. […]

This article delves into how DMS, as a structured approach, significantly enhances operational efficiency and productivity in manufacturing environments. Through real-world examples and best practices, we explore the transformative impact of DMS on streamlining workflows, improving team collaboration, and fostering a culture of continuous improvement. Discover the key strategies and tools that make DMS an essential component for modern manufacturing success.

Our article provides an in-depth look at tiered meetings, a structured approach to organizing meetings across different levels of management. We explain how dividing meetings into Tier 1, Tier 2, and Tier 3 can lead to more targeted and efficient discussions, relevant to each level of the organization. The piece addresses common problems in traditional meeting setups, such as prolonged sessions and unprepared participants, and suggests practical ways to overcome these issues. It also highlights the role of digital tools in enhancing meeting productivity and accountability. Focusing on applications in the manufacturing and health sectors, the article offers insights into adapting the tiered meeting structure to various organizational contexts. This method aims to improve communication flow and decision-making efficiency in businesses.

Definition: In manufacturing, Gemba Walks involve management walking around a factory floor to identify problems and ideas for improvement.

Five steps, one system: 5S is a must for any worksite to organize and optimize its operations. It reduces daily inefficiencies, improves workplace safety, and minimizes time, movement, and resource waste. Over time, though, a 5S audit must come into play to prevent standards from going wayward. The question then is, how can one conduct […]

Defining Lean Daily Management (LDM) Lean Daily Management (LDM) is a systematic strategy for building Lean habits and managing continuous improvement and daily operations in the workplace. It involves multiple aspects, such as Leader Standard Work and Lean management routines, visual management boards, daily accountability, and problem-solving where the work happens (Gemba). LDM improves efficiency, […]

What Is the 5S Methodology in Lean Manufacturing? 5S is a prevalent Lean manufacturing method in factories and plants that helps organize the workspace, optimize performance, and ensure a safer workplace. Its goal is simple: create a safe, orderly environment conducive to productivity at every workstation. In this article, we’ll delve into the setup of […]

Defining Shop Floor Management Shop Floor Management (SFM) is a leadership structure within Lean management aiming to streamline manufacturing operations on the shop floor, optimize daily management processes, and further cooperation between employees and management. SFM coordinates efficient production and ensures standardization, waste reduction, safety protocols, continuous improvement, and quality control. Evolution and Global Adoption […]

A Gemba Walk is an operational control practice aiming to systematically validate standards, identify issues proactively, and generate improvement opportunities. A Gemba Walk structure ensures all management levels walk in the workplace. It involves going to the work area with a checklist, observing operations, engaging with employees, and asking questions. Using the right tool will […]

Table of Contents What Is a Gemba Walk Checklist? Used in Lean management, a Gemba Walk Checklist is a form containing a series of checkpoints and questions validated by managers during their regular Gemba Walk. Thanks to its structured approach, team leaders, managers, and directors go to the workplace (or Gemba in Japanese) to identify […]

This guide provides a straightforward and insightful resource to understand and implement a Layered Process Audit (LPA). Discover the 12 steps for integrating LPAs into operational frameworks. What Is a Layered Process Audit? Layered Process Audits (LPAs) are structured evaluations spanning multiple organizational levels to ensure adherence to established processes and enhance performance. Frontline employees, […]

Defining the PDCA and the Deming Cycles The PDCA cycle (Plan Do Check Act) is a methodology to develop and customize internal organizational procedures for quality, project, and problem management. The Deming cycle is the visual representation of that model. In other words, while the PDCA cycle is a systematic method for continuous process improvement, […]

Do your supervisors and managers need to be more accountable regarding your performance objectives? Do they have regular management routines (process audits, 5S audits, safety inspections, Gemba Walks, meetings)? Without Leader Standard Work and Lean Leadership Routines, you’re likely seeing skills gaps between your different team leaders. Address this challenge by implementing Leader Standard Work. […]

The CQI-8 Layered Process Audit Guideline is an initiative from the Automotive Industry Action Group (AIAG) to improve quality and processes with a suggested framework for managing Layered Process Audits. LPAs can help to reduce the cost of poor quality (CoPQ) by conducting audits at every layer of the organization, not just focusing on the […]

Tervene Unveils Its New Platform to Help Manufacturers with Daily Management and Performance Improvement Version 2.0 of the software standardizes management processes and accelerates digital transformation in the manufacturing and industrial sectors. MONTREAL, October 12, 2023 / Tervene, a Canadian technology company offering a daily management solution, unveils the latest version of its platform, featuring […]

Maximizing performance is as complex as crucial in the industrial and manufacturing sectors. That’s why it’s essential to establish a continuous improvement culture. By anchoring this approach in the core of operations, achieving objectives and improving performance becomes a reality. What Is Continuous Improvement Culture or Kaizen? Continuous improvement culture, also known as Kaizen, is […]

Auditing processes in the manufacturing, distribution, and healthcare sectors is not merely a luxury; it’s the cornerstone of any organization striving for excellence in its products and services. Maintaining high-quality, safe, and efficient procedures cannot be overstated since the repercussions of subpar standards can be damaging, leading to lost customers, rework, product recalls, and reputational […]

Createch and Tervene team up to offer operational performance consulting services and daily management solutions (DMS). [Montréal, September 20th, 2023] – Createch, a leader in digital transformation and operational performance improvement, is pleased to announce its new strategic partnership with Tervene, a company dedicated to the development of Daily Management System (DMS) software for the […]

What is a Safety Walk? What is a Health and Safety Checklist? Who Usually Conducts Safety Walks? Benefits of Implementing Safety Walks and Checklists Case Study : Health and Safety Inspections at TOMRA Canada Steps to Implement Safety Inspection Checklists in a Manufacturing Environment Workplace Safety Inspection Checklist (Example) Safety Checklist Questions for Manufacturers (Example) […]

In factories, daily production meetings and huddles are essential for maintaining a smooth workflow, keeping employees informed about progress, and addressing any issues that may arise. However, these meetings can quickly become ineffective if they are not structured properly. Here are some tips for running effective daily production meetings and factory team huddles: Segregate meetings […]

In today’s manufacturing industry, implementing a robust quality management system is essential for ensuring product quality, reducing defects, managing deviations from standards, and preventing the problem from occurring again. One such system is the Quick Response Quality Control (QRQC) system, a process designed to quickly identify and resolve quality issues. QRQC Origin The Quick Response […]

Leader Standard Work involves creating a standard set of tasks and activities that a manager should perform on a daily, weekly, or monthly basis. We’ll explore Leader Standard Work (LSW) in detail, discussing the benefits of implementing an LSW calendar, providing examples of tasks that should be included, and offering template ideas. Table of Contents: […]

The manufacturing industry has a wide range of specific workforce challenges. Unfortunately, it can be difficult to find ways to deal with these issues, especially when your daily time and energy are limited. What are the primary workforce challenges in manufacturing, and how can you overcome them to ensure organizational health? Here you’ll find useful […]

Digital Daily Management System (DMS) at Safran Cabin Safran Cabin Canada, formerly Zodiac Aerospace One of our most important considerations was that our supervisors needed to manage lots of different issues at a time. We needed a solution that would structure the flow of information, but that could also structure our Gemba Walk program. Michel […]

In a manufacturing context with many growing industries, it is frequent for factories to add continuous work shifts in order to keep a production pace that answers the growing demand. However, while necessary, these additional work shifts add a level of complexity to the business’s operations workflow. More specifically, operations managers must deal with having […]

Frontline managers are essential to support daily operations. They coordinate shifts and work teams, ensure production planning, prioritize problem-solving and follow action plans with the support groups. Manufacturers that sustain excellent supervision practices get better control over daily operations. Thus, they improve synergy between operators, support groups and top management. Although some supervisors acquire good […]

The daily management of a factory and its operations is full of unexpected events and emergencies. To remain in complete control, each management level wants to anticipate and quickly solve the encountered issues. For some organizations, it can be hard to proactively identify problems, while supporting an internal improvement culture, before the problems negatively impact […]

As a response to new health & safety risks and requirements, organizations have rapidly deployed measures to maintain a safe and compliant workplace while supporting daily operations. The pressure of the Covid situation has created a strong increase of digital initiatives in businesses. Many EHS managers set up connected tools to manage safety as part […]

Discover how Tervene equips your frontline teams and supports your daily operation control. Request a copy of our brochure: Download and save the brochure to read later or share with your team. In this brochure, you’ll get: What is Tervene? Your daily operation control with Tervene Tervene’s features overview Customer testimonials Our professional coaching services

How to Perform Continuous Improvement with Tervene In a few words: ✓ Identify improvement opportunities ✓ Log and document opportunities ✓ Schedule improvement meetings ✓ Prioritize improvement ideas ✓ Manage improvement projects ✓ Track action plan progress Related blog post: How Gemba Walks Sustain Continuous Improvement Identify Improvement Opportunities In order to generate ideas for […]

What is a Gemba Walk? In the manufacturing industry, a Gemba Walk is the action of walking around a factory floor where operations take place in order to reduce Waste and improve processes. Managers perform this operational control to identify discordances with the standard and raise issues. A Gemba Walk is a proactive problem-solving practice […]

Gemba Walks enable supervisors and managers to detect, solve and transfer issues proactively. Otherwise, these problems impact performance indicators negatively and bring time-consuming activities in the manager’s daily work. One of the causes of a reactive system is managing in a firefighter mode. Why is Measurement Important? The main challenge is to conduct a standard […]

What’s New? In order to increase Tervene’s accessibility, our Connected Management System is now available on mobile and Android devices. In other words, workers and managers can perform Gemba Walks and audits with their smartphones. Supported Operating Systems and Devices Apple: App Store iPad iPhone (NEW) Android: Google Play Store Smartphone (NEW) Tablet (NEW) Microsoft: […]

Which Type of Organization? Gemba Walks are a common practice on the production floor in the manufacturing industry. Performed regularly, Gemba Walks are an essential part of operational control and support a strong continuous improvement culture. Ultimately, Gemba Walks are useful for all organizations with the need to detect issues and generate improvement ideas proactively. […]

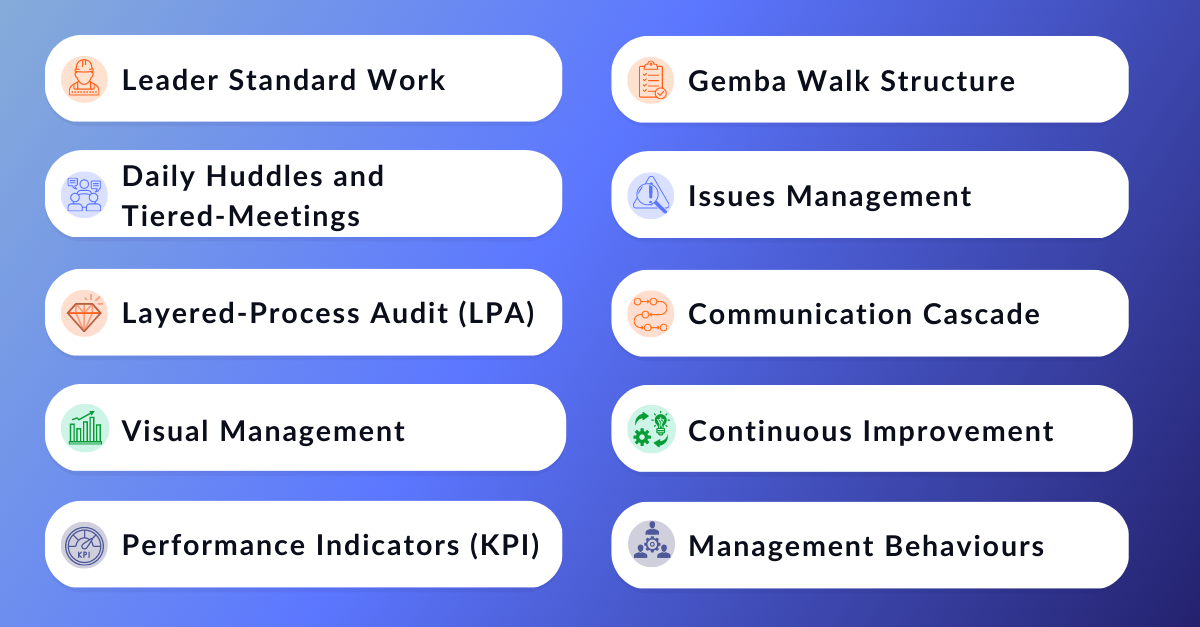

What is a Daily Management System? A Daily Management System (DMS) is a complete system that structures daily operational controls as well as continuous improvement to reach operational excellence. All levels of management know the performance of their processes, identify discrepancies from the objectives, follow key indicators and take corrective action quickly. DMS’ role Align […]

Manufacturing managers face unprecedented challenging times caused by COVID-19. While some essential companies have never stopped producing, other factories are currently planning and coordinating a reopening with the greatest concern for health and safety measures. Managers have to deal with the implementation of social distancing measures, new procedures deployment, quality issues, reduced frontline workers access on […]

A Daily Management System, commonly referred to as DMS, is the structure by which organizations conduct operational management to ensure their day-to-day goes as planned and continuously improves. In other words, it encompasses all of the operational control activities, from the factory floor to the highest management levels.

Digital tools enable task management standardization. As a result, it is possible to prioritize, assign and monitor tasks much more effectively. Using a standard tool, everyone within the organization can collaborate.

How to implement a systematic Gemba Walk Structure on the factory floor? Checklists, schedule, improvement meetings and more. (+ Free eBook)

In this series, Management practices digitalization, we’ll explore the differences between traditional methodologies and Tervene’s approach to operations management. Discover how Tervene sets the table to a successful digital transition for meetings.

In this series, Management practices digitalization, we’ll explore the differences between traditional methodologies and Tervene’s approach to operations management. Discover how Tervene sets the table to a successful digital transition for inspection processes.

In this series, Management practices digitalization, we’ll explore the differences between traditional methodologies and Tervene’s approach to operations management. Discover how Tervene sets the table to a successful digital transition for operational control.

The partnership combines Toptech’s expertise in operational excellence with Tervene’s tool for digitizing and standardizing the management of manufacturing operations.

Tervene now offers live support from within the app! Click this post to see how to use it.

Looking for a continuous improvement software? Here are the minimal features you should require.